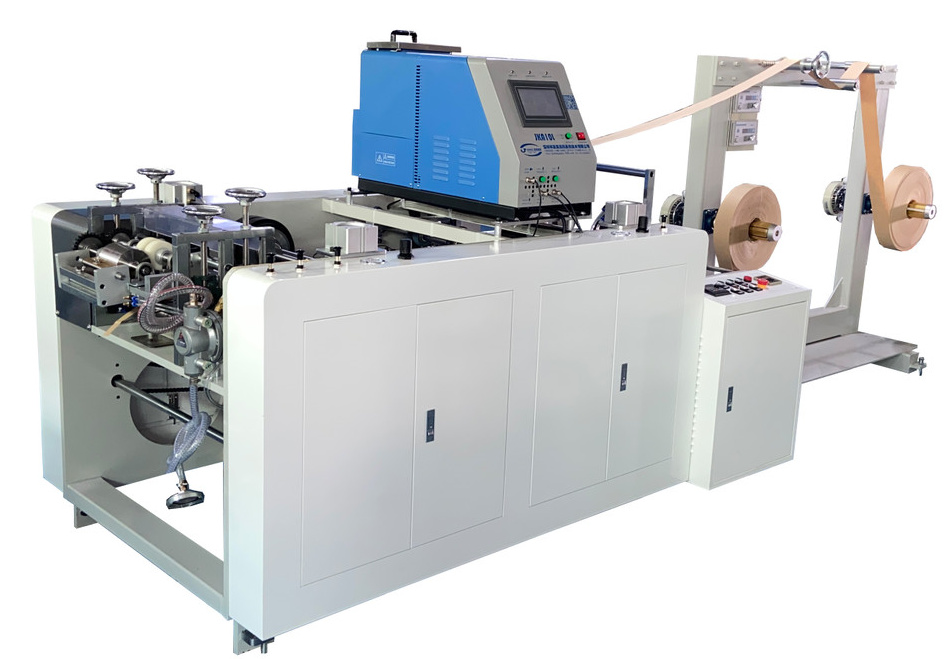

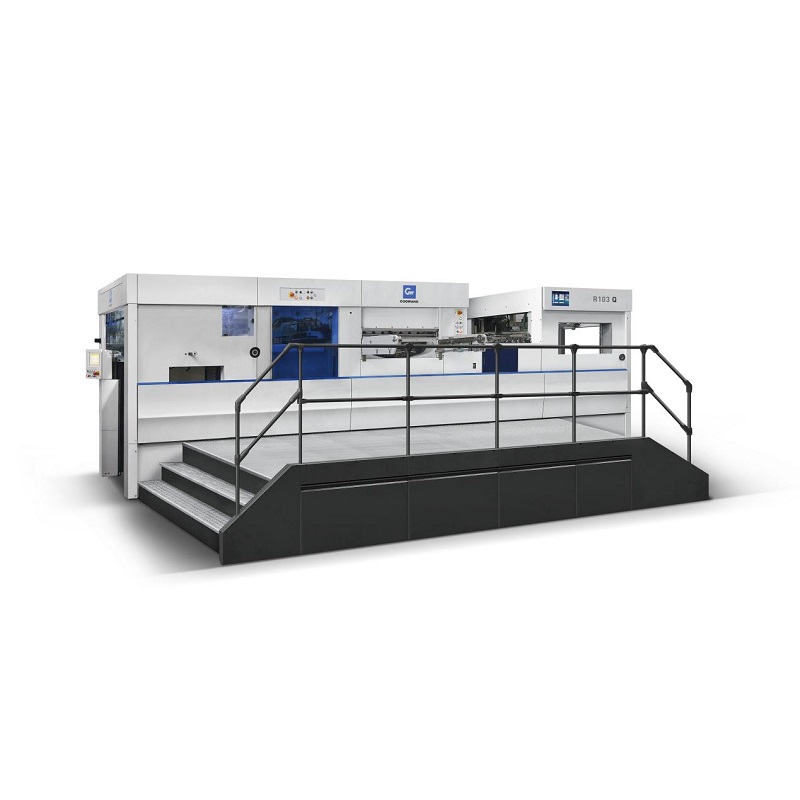

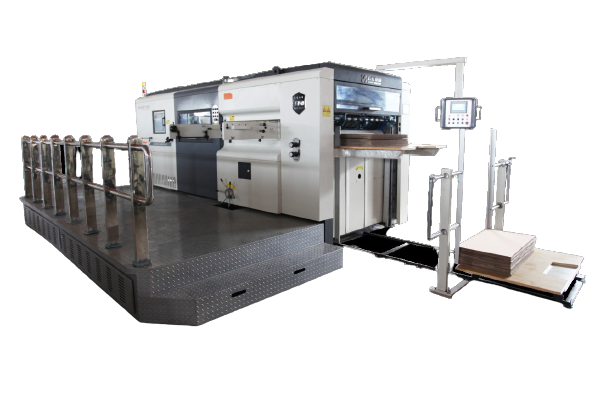

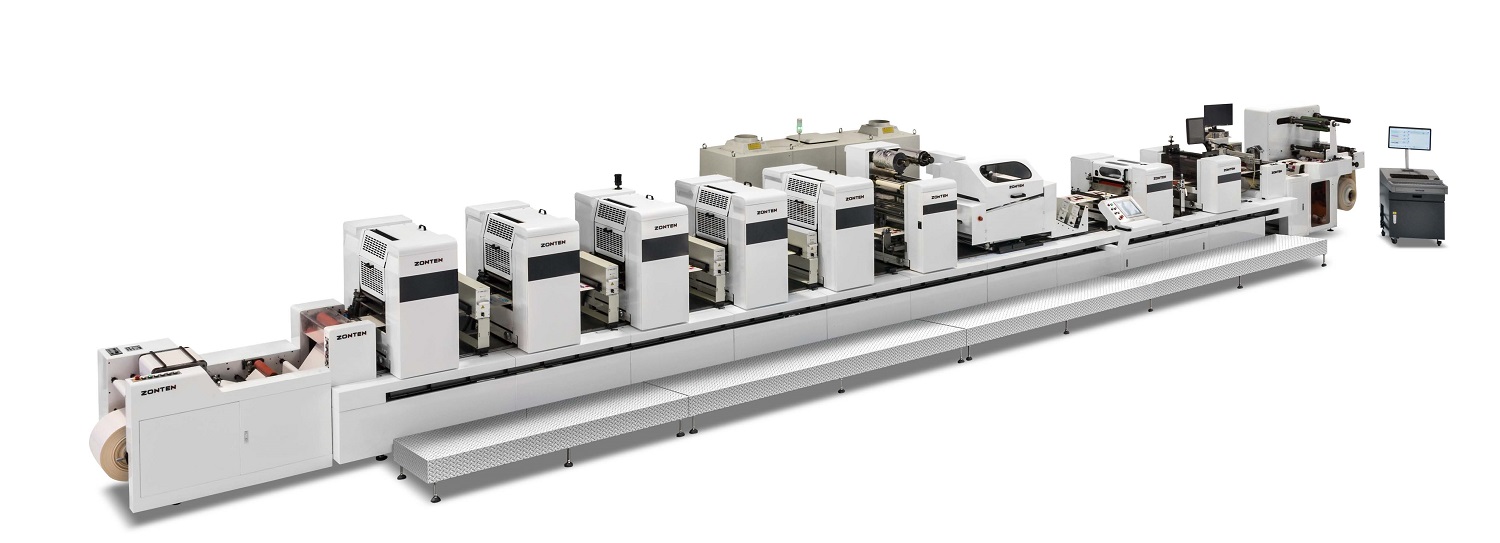

We adopts the advanced production solution and 5S management standard. from R&D, purchasing, machining,assembling and quality control, every process strictly follow standard. With a rigid system of quality control, each machine in the factory should pass the most complex checks tailored individually for related customer entitled to enjoy the unique service.