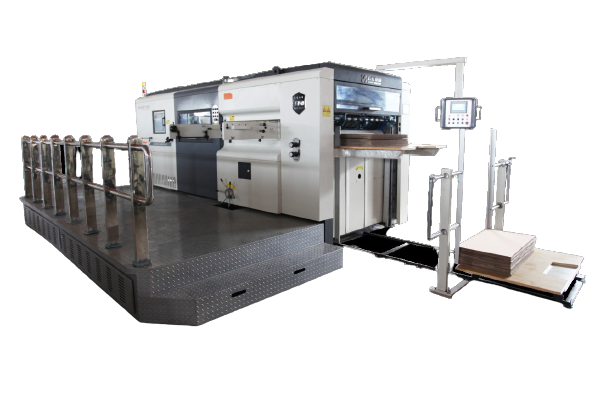

Century MWB 1450Q (with stripping) Semi-Auto Flatbed Die Cutter

| Model | MWB1450Q |

| Max. Paper Size | 1480*1080 mm |

| Min. Paper Size | 550*480 mm |

| Max. Cutting Size | 1450*1050 mm |

| Max. Cutting Pressure | 300x104N |

| Stock Range | Corrugated board ≤ 9 mm |

| Die Cutting Accuracy | ±0.5 mm |

| Max. Mechanical Speed | 4000s/h |

| Pressure adjustment | ±1 mm |

| Minimum Front Margin | 8MM |

| Inner Chase Size | 1480*1080 mm |

| Total Power | 21KW (exclude the work platform |

| Machine Dimension | 7750*4860*2440 mm (Include the work platform, pre-feeder) MWB1620Q |

| Machine Dimension | 5140*2605*2240 mm (Exclude the work platform, pre-feeder) MWB1620Q |

| Total Weight | 19t |

Feeding Section

√Effective manual feeding system.

√Automatic sheet pile lifting system.

√Side guide to position paper pile center.

√Applicable to E, B, C, A flute and double wall.

Die Cutting Section

√ Pneumatic push button die-chase locking mechanism to ensure safe and operator friendly changing of the die-cutting plate.

√Center line system for quick cutting die set up and change.

√ Knuckle system for maximum cutting pressure up to 400 tons

√Automatic and independent Self-lubrication system for smooth operation and longer lifespan

√Safety door and photo-electrical device for safe operation.

Stripping Section

√ Upper stripping frame can be lifted up for stripping die install and change.

√Centerline system for quick stripping die set up and job change

√Frame lock device, flexible and easy to lock and loosen the stripping die.

√Photo-sensor and safety window equipped for safe operation.

√Semi-stripping system leaves the gripper edge not stripped.

Delivery Section

√Side and front joggers to ensure neat stacking.

√Pallet delivery system

√Photoelectric detective device for safety entrance and operation.

Electrical Control Section

√Siemens PLC l technology to ensure trouble free running.

√Electrical components are from Siemens, Schneider.

√All electrical components meet CE standard

| Part name | Brand |

| Main bearing | NSK |

| Main drive chain | RENOLD |

| Frequency Inverter | YASKAWA |

| Electrical Components | Siemens/Schneider |

| Encoder | OMRON |

| Photo sensors | Panasonic/Omron |

| Main motor | Siemens |

| Pneumatic component | AirTac/SMC |

| PLC | Siemens |

| Touch Panel | Siemens |

Pre-Feeder

This pre-feeder helps make the next sheets pile ready and do the quick change of sheets pile. When the operator is feeding the sheets to the die cutter, another operator can prepare another sheets pile at the same time. Once sheet in-feeding is finished, the sheets pile prepared on the pre-feeder can be pushed to automatic pile lifting device. This will save about 5 mins of preparing the sheets pile each and increase the productivity.

Operation panel with moveable arm// Siemens Smart line Touch Panel

Feeding Section

√Camera to monitoring the condition of delivery section inside

√Automatic pile lifting system

√Adjustment device of infeed gap between the sheets and grippers.

√Safety window and photo-sensor offer protection for operator and machine when the safety window is open.

√Pressing plate to ensure the sheets never over-fed to die cutter

√Side joggers to keep the pile always in the center and achieve easy and accurate sheets infeed.

Photo sensor to keep the pile lifting always in time for sheets feeding.

Die Cutting Section

√Die cutting plate is made of 65Mn with hardness of HRC45, suitable for die cutting.

√Safety window equipped for operator’s and machine’s safety.

√Center line system for quick cutting die set and job change.

√Cutting force adjustment handle. Easy and simple.

Worm wheel with hand grinding craft to guarantee the smoothness of the surface for accurate die cutting.

Automatic self-lubrication system

Mono-cast made for less vibration when machine running.

Support apron can be adjusted to different sizes for different sheets’ size.

Delivery Section

√Non-stop pallet delivery system

√Operation panel

√Safety window

√Photo sensor equipped to make sure that the machine will stop when something enters the machine at this section.

√Side joggers for neat sheets collecting

Viewing window for checking the sheets collection and do some necessary adjustment if needed.

Sheet format adjustment device

Electrical Control

CPU Module//Siemens Simatic S7-200

Yaskawa Frequency Inverter

Schneider relays, contactors and so on.

Gripper bars, which is made of aerospace aluminum material.

Two extra sets of gripper bars will be shipped along with the machine as spare parts.

-300x179.jpg)

-300x204.jpg)

-300x179.jpg)

-300x200.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)