Flatbed Diecutting

-

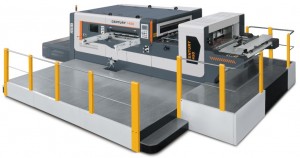

GUOWANG T-1060BN DIE-CUTTING MACHINE WITH BLANKING

T1060BF is the innovation by Guowang engineers to perfectly combine the advantage of BLANKING machine and traditional die-cutting machine with STRIPPING, T1060BF(2nd generation) has all the same feature as T1060B to have a fast, accurate and high speed running, finishing product piling and automatic pallet change( Horizontal delivery ), and by one -button, machine can be switch to traditional stripping job delivery( Straight line delivery ) with motorized non-stop delivery rack. No mechanical part need to be replaced during the process, it is the perfect solution for customer who need a frequent job switching and fast job changing.

-

GUOWANG R130 AUTOMATIC DIE-CUTTER WITHOUT STRIPPING

Pneumatic lock system makes easier lock-up and release of cutting chase and cutting plate.

Pneumatic lifting cutting plate for easy slide in and out.

Centerline system on die-cutting chase with transversal micro adjustment ensures accurate registration that result in quick job changeover.

Accurate positioning of Cutting chase controlled by precision optical sensors with automatic check-lock device.

Cutting chase turnover device.

Siemens main motor controlled by Schneider inverter.

-

GUOWANG R130Q AUTOMATIC DIE-CUTTER WITH STRIPPING

The side lays can be switched directly between pull and push mode on both sides of the machine simply by turning a bolt without having to add or remove parts. This provides the flexibility for processing a wide range of material: irrespective of whether the register marks are to the left or right of the sheet.

Side and front lays are with precision optical sensors, which can detect dark color and plastic sheet. The sensitivity is adjustable.

Optical sensors with automatic stop system on feeding table enable you to optimize system monitoring- for comprehensive quality control over the entire sheet width and paper jam.

Operation panel for feeding part is easier to control the feeding process with LED display.

-

GUOWANG T-106Q AUTOMATIC FLATBED DIE-CUTTER WITH STRIPPING

T106Q is a highly automated and ergonomic die-cutter on the market. This top of the range machine delivers unmatched productivity thanks to many features for fast, uninterrupted production, short set-up times, while also providing high cost efficiency rate to keep you competitive in the industry.

-

GW double station die-cutting and foil stamping machine

Guowang Automatic Double Station Die-cutting and Hot Foil-stamping Machine can realize a various of different combination by customer’s demand.

First unit can reach 550T pressure. so that you can have Large area stamping+deep embossing+ hot foil-stamping+stripping in one run.

-

Automatic Flatbed Die-cutting Machine MWZ1450QS for Cardboard Corrugated

Suitable for cardboard from 90-2000gsm and corrugated board ≤4mm high speed die-cutting and stripping. Automatic feeding and delivery.

Max. Speed 5200s/h Max. Cutting pressure 300T

Size: 1450*1050mm

High speed, high accuracy, quick job change over.

-

Automatic Flatbed Die-cutting Machine MWZ-1650G

Suitable for 1≤corrugated board≤9mm high speed die-cutting and stripping.

Max. Speed 5500s/h Max. Cutting pressure 450T

Size: 1630*1180mm

Lead edge/Cassette style feeder/Bottom suction feeder

High speed, high accuracy, quick job change over.

-

Century MWB 1450Q (with stripping) Semi-Auto Flatbed Die Cutter

Century 1450 model is able to handle corrugated board, plastic board and cardboard for display, POS, packaging boxes etc.

-

GUOWANG C80Q AUTOMATIC DIE-CUTTER WITH STRIPPING

High quality feeder with 4 suckers for lifting paper and 4 suckers for forwarding paper ensure stable and fast feeding paper. The height and angle of suckers are easily adjustable to keep sheets absolutely straight.

Mechanical double-sheet detector, sheet-retarding device, adjustable air blower ensure sheets transfer to the belt table steadily and precisely.

Vacuum pump is from German Becker. -

MWZ1620N Lead Edge Automatic Die Cutting Machine with Full Stripping Section

Century 1450 model is able to handle corrugated board, plastic board and cardboard for display, POS, packaging boxes etc.

-

GUOWANG C106Q AUTOMATIC DIE-CUTTER WITH STRIPPING

Perfect piles can be formed on pallets which run on rails for pre-load system. This makes a significant contribution to smooth production and let operator move the prepared pile to feeder accurately and conveniently.

Single position engagement pneumatic operated mechanical clutch insures the first sheet after every re-start of machine is always fed to front lays for easy, time-saving and material-saving make-ready.

The side lays can be switched directly between pull and push mode on both sides of the machine simply by turning a bolt without having to add or remove parts. This provides the flexibility for processing a wide range of material: irrespective of whether the register marks are to the left or right of the sheet. -

EC-1450Q AUTOMATIC FLATBED DIE-CUTTER With Stripping (TOP FEEDER) QUOTATION LIST

Built for quick set-up, safety, wide range stock and reducing damages to print sheets.