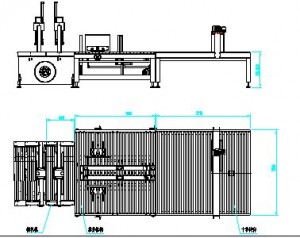

Automatic PE Bundling Machine JDB-1300B-T

a)Specifications

|

Model |

JDB-1300B-T |

|

Max Bundle Size |

1300*1200*250mm |

|

Min Bundle Size |

430*350*50mm |

|

PE Rope |

50# |

|

Bundle Speed |

8-16 Packages /Min |

|

Air Pressure |

0.4~0.8MPA |

|

Power Supply |

3PH 380V |

|

Main Power |

3.5kw |

|

Dimension |

3900*2100*2100mm |

|

Machine Weight |

2500KG |

b) Carton Size Comparison Table

|

Note |

Max |

Mini |

|

A |

1300mm |

430mm |

|

B |

1200mm |

350mm |

|

C |

250mm |

50mm |

● High safety standard: The rope arm will be disengaged and come back to its start position when resistance is detected. The pusher will stop the machine if resistance is found. With the door open, the machine can not run.

● Beak using Chromium-molybdenum alloy processed by a special procedures makes it more wear and tear with long service life.

● Driving gears are made of 45# steel dealt with high frequency heat treatment to increase its wear resistance.

● High efficiency, 8-16 bales per minute.

● Digital adjustment via touch screen easy to operate and understand.

● Digital adjustment via touch screen easy to operate and understand.

● Machine is equipped with automatic oil supply system which can lubricate the machine in time. Each input and output of electrical appliance is connected with monitoring points in touch screen to facilitate machine’s maintenance.

● Cost saving. PE only takes 0.17 Cents for one meter.

Bundling unit

1. Using pneumatic pressing structure, it makes the bundle tightness suitably and protect the paper pile effectively.

2. Using 4 unique torsion control structures, combine with rope feeding arms to achieve protection functions. The arms will stop working if definite resistance happen between the arm and paper pile, this function will protect the operator and machine.

3. Beak using Chromium-molybdenum alloy processed by a special procedures makes it more wear and tear with long service life.

Lubrication system

Multiply points lubrication system provide oil into the machine, the oil will transport to the pre set position, the oil volume and frequency can be set. This function can effective protect the machine.

|

Name |

Brand |

Specification |

Model |

Quantity |

|

PLC-30 |

|

V-TH141T1 |

|

1 |

|

Contactor |

Schneider |

E-0901/E-0910 |

|

11 |

|

Button |

TAYEE |

IEC60947 |

24V |

7 |

|

Photoelectric Switch |

ORMON |

E3F3-D11/E3Z-D61/E3FA-RN11 |

|

4 |

|

Air Switch |

CHINT |

DZ47-60 |

C20 |

1 |

|

Relay |

Schneider |

NR4 |

2.5-4A/0.63-1A/0.43-63A |

8 |

|

Magnetic Valve |

AIRTAC |

4V21008A |

AC220V |

6 |

|

Encoder |

OMRON |

E6B2-CWZ6C |

|

2 |

|

Touch Screen |

HITECH |

PWS5610T-S |

|

1 |

Tools

|

|

Name |

Quantity |

|

1 |

1 |

|

|

2 |

Screwdriver (plus) |

1 |

|

3 |

Screwdriver (minus) |

1 |

|

4 |

Pliers |

1 |

|

5 |

Monkey wrench |

1 |

|

6 |

Wrench |

3 |