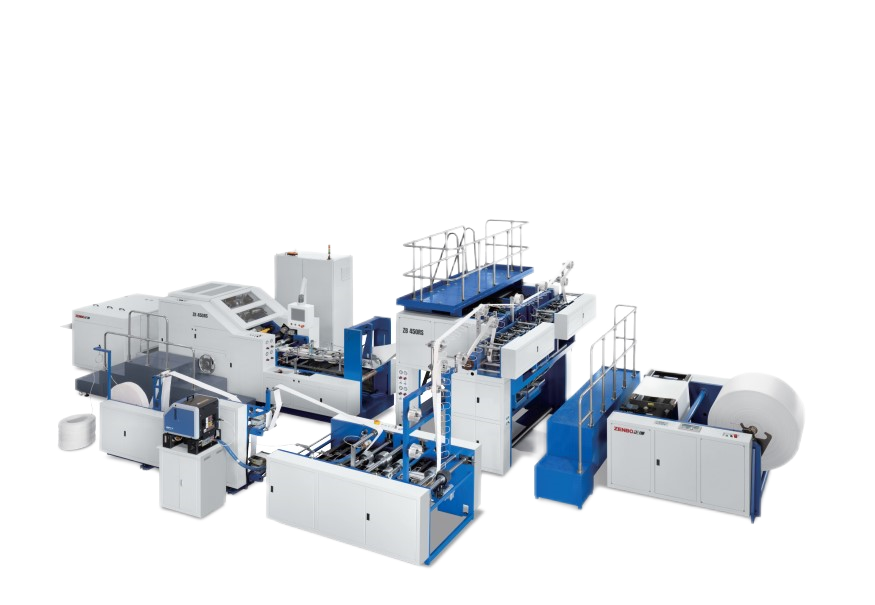

Fully Automatic Roll Feeding Paper Bag Making Machine ZB460RS

ZB460RS Fully automatic Roll feeding square bottom paper bag machine .Is designed for the production of paper bags with twisted handles. It is suitable for mass production of shopping bags in industries such as food and clothing. The one-line process consists of twisted handles making from paper rolls and twisted rope, delivery of handles to paste unit, pre-cutting of paper on position of rope, patch position gluing, handle pasting, and paper bag making. The paper bag making process consists of side gluing, tube forming, cutting, creasing, bottom gluing, bottom forming and bag delivery.

The speed of the machine is fast and the output is high. Greatly saves the labor cost. Humanized intelligent operation interface, Mitsubishi PLC、 motion controller and servo transmission system not only ensure the high speed operation of the machine, but also ensure the high precision of paper bag size.

| Model: ZB460RS | ||

|

Paper Roll Width |

670--1470mm |

590--1470mm |

|

Max.Paper Roll Diameter |

φ1200mm |

φ1200mm |

|

Core Diameter |

φ76mm(3") |

φ76mm(3") |

|

Paper Thickness |

90--170g/㎡ |

80-170g/㎡ |

|

Bag Body Width |

240-460mm |

200-460mm |

|

Paper Tube Length(cutt off length) |

260-710mm |

260-810mm |

|

Bag Bottom Size |

80-260mm |

80--260mm |

|

Handle Rope Height |

10mm-120mm |

------ |

|

Handle Rope Diameter |

φ4--6mm |

------ |

|

Handle Patch Length |

190mm |

------ |

|

Paper Rope Center Distance |

95mm |

------ |

|

Handle Patch Width |

50mm |

------ |

|

Handle Patch Roll Diameter |

φ1200mm |

------ |

|

Handle Patch Roll Width |

100mm |

------ |

|

Handle Patch Thickness |

100--180g/㎡ |

------ |

|

Max Production Speed |

120bags/min |

150bags/min |

|

Total Power |

42KW |

|

|

Overall Diamension |

14500x6000x3100mm |

|

|

Total weight |

18000Kg |

|

1.Adjustable roll to square bottom bag making machine

2.Introduce In-touch screen human-machine interface, easy for correction and fine adjustment. Alarm and working status can be displayed in screen on-line, easy for operation and maintenance.

3.Equipped with Mitsubishi PLC and motion controller system and SICK photocell for correction, tracking the printed material accurately, minimize the adjustment and preset time, increase the production efficiency.

4.Human oriented security protection, whole housing design, ensure the safety of operator

5.hydraulic material loading system.

6.Automatic constant tension control for unwinding, web guider system, motor for material feeding with inverter, minimize the adjustment time for web alignment.

7.High speed oriented design ensure successful of production: within the suitable paper range, production capacity can reach 90~150pics/min, . Increased the unit production capacity and higher profit.

8. SCHNEIDER electric system, ensure better stability and reliability; perfect after sale service, trouble free for customer.

|

No. |

Name |

Origin |

Brand |

No. |

Name |

Origin |

Brand |

|

1 |

Servo motor |

Japan |

Mitsubishi |

8 |

Photoelectric sensor |

Germany |

SICK |

|

2 |

Frequency converter |

France |

Schneider |

9 |

Metal proximity switch |

Korea |

Autonics |

|

3 |

Button |

France |

Schneider |

10 |

Bearing |

Germany |

BEM |

|

4 |

Electric relay |

France |

Schneider |

11 |

Hot melt glue system |

USA |

Nordson |

|

5 |

Air switch |

France |

Schneider |

12 |

synchronized belt |

Germany |

Contitech |

|

6 |

Frequency converter |

France |

Schneider |

13 |

Remote Controller |

China Taiwan |

Yuding |

|

7 |

Power switch |

France |

Schneider |

|

|

|

|