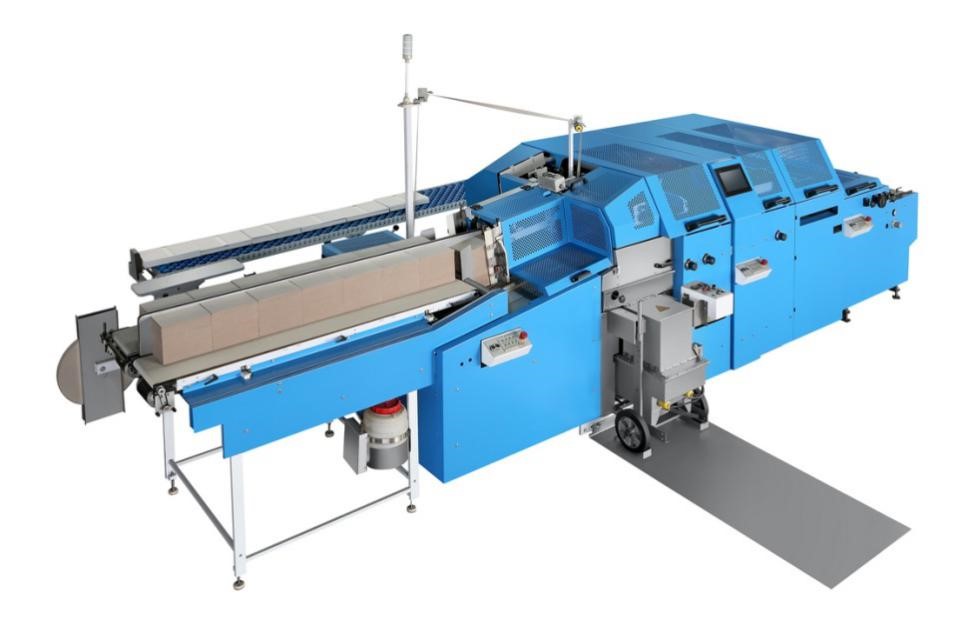

HCM390 Automatic high speed case maker

|

No. |

Model | HCM390 |

|

1 |

Case size(A×B) | MIN: 140×205mm

MAX: 390×670mm |

|

2 |

Paper size (W×L) | MIN: 130×220mm

MAX: 428×708mm |

|

3 |

Paper thickness | 100~200g/m2 |

|

4 |

Cardboard thickness (T) | 1~4mm |

|

5 |

Spine size (S) | 8-90mm |

|

6 |

Spine thickness | >200g&1-4mm |

|

7 |

Folded paper size(R) | 8~15mm |

|

8 |

Max. quantity of cardboard | 3pieces |

|

9 |

Precision | ±0.30mm |

|

10 |

Production speed | ≦65sheets/min |

|

11 |

Power | 8kw/380v 3phase |

|

12 |

Air supply | 28L/min 0.6Mpa |

|

13 |

Machine weight | 5800kg |

|

14 |

Machine dimension (L×W×H) | L6200×W3000×H2450mm |

Write your message here and send it to us