OTHER PRODUCTS

-

Automatic round rope paper handle pasting machine

This machine is mainly supporting semi-automatic paper bag machines. It can produce the round rope handle on line ,and stick the handle on the bag on line too, which can be attached onto the paper bag without handles in further production and make it into paper handbags.

-

EUD-450 Paper bag rope insertion machine

Automatic paper/cotton rope inserting with plastic ends for high quality paper bag.

Process: Automatic bag feeding, non-stop bag reloading, rope wrapping plastic sheet, automatic rope insertion, counting and receiving bags.

-

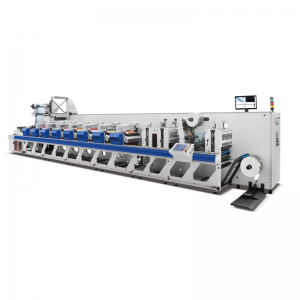

ZJR-450G LABEL FLEXO PRINTING MACHINE

7 colors flexo printing machine for label.

There are 17 servo motors in total for 7 colors machine which ensure the accurate registration running at high speed.

Paper and adhesive paper: 20 to 500 Grams

Bopp , Opp , PET ,PP, Shink Sleeve, IML , Etc, Most Plastic film. (12 micron -500micron )

-

YT-360 Roll feed Square Bottom Bag Making Machine with Inline Flexo Printing

1.With original Germany SIMENS KTP1200 human-computer touch screen, it is easy to operate and control.

2.Germany SIMENS S7-1500T motion controller, integrated with profinet optical fiber,ensure the machine with high speed steadily.

3.Germany SIMENS servo motor integrated with original Japan Panasonic photo sensor, continuously correcting slightest of the printed paper accurately.

4.Hydraulic up and down web lifter structure, integrated with constant tension control unwinding system.

5.Automatic Italy SELECTRA Web guider as standard, continuously correcting slightest alignment variations fast.

-

RKJD-350/250 Automatic V-Bottom Paper Bag Machine

Paper bag width:70-250mm/70-350mm

Max. Speed: 220-700pcs/min

Automatic paper bag machine for producing various sizes of V-bottom paper bags, bags with window, food bags, dried fruit bags and other environmentally friendly paper bags.

-

Automatic PE Bundling Machine JDB-1300B-T

Automatic PE Bundling Machine

8-16 bales per minute.

Max Bundle Size : 1300*1200*250mm

Max Bundle Size : 430*350*50mm

-

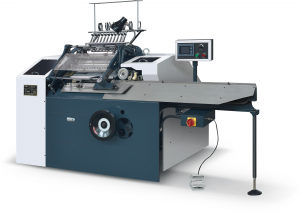

SXB460D semi-auto sewing machine

max binding size 460*320(mm)

min binding size 150*80(mm)

needle groups 12

needle distance 18 mm

max speed 90cycles/min

power 1.1KW

dimension 2200*1200*1500(mm)

net weight 1500kg -

SXB440 semi-auto sewing machine

max binding size: 440*230(mm)

min binding size: 150*80(mm)

number of needles: 11 groups

needle distance: 18 mm

max speed: 85cycles/min

power: 1.1KW

dimension: 2200*1200*1500(mm)

net weight: 1000kg” -

BOSID18046High Speed Fully Automatic Sewing Machine

Max. speed:180times/min

Max.binding size(L×W):460mm×320mm

Min.binding size(L×W):120mm×75mm

Max.number of needles:11guoups

Needle distance:19mm

Total power:9kW

Compressed air:40Nm3 /6ber

Net weight:3500Kg

Dimensions(L×W×H):2850×1200×1750mm -

WF-1050B Solventless and solvent base laminating machine

Suitable for the lamination of composite materials of 1050mm width

-

Roll Feeder Die Cutting&Creasing Machine

Max Cutting Area 1050mmx610mm

Cutting Precision 0.20mm

Paper Gram Weight 135-400g/㎡

Production Capacity 100-180 times/min

Air Pressure Requirement 0.5Mpa

Air Pressure Consumption 0.25m³/min

Max Cutting Pressure 280T

Max Roller Diameter 1600

Total Power 12KW

Dimension 5500x2000x1800mm

-

ASZ540A 4-Side Folding Machine

Application:

The principle of 4-Side Folding Machine is feeding surface paper and board which has been positioned through Pre-pressing, Folding left and right sides, Pressing corner, Folding front and rear sides, Pressing evenly process, which all automatically realizes four sides folding.

This machine combined with features in high-precision, fast speed, prefect corner folding and durable side folding. And the product is widely applied in making Hardcover, Notebook, Document folder, Calendar, Wall calendar, Casing, Gifting box and so on.