KMM-1250DW Vertical Laminating Machine (Hot Knife)

FEEDER

Driven by servo motor

Feeding: Up & down pile facilities

Pile loading facilities: Yes

Dry suction and blowing pump

Automatic motorized loading platform with auto protection function

Gates: Yes (precise overlapping +/- 1.5mm)

Electronic overlap control

COATING UNIT

Driven by servo motor

Coating device by rolls system: Yes

Suitable for multi-type glue

DRYER

Stable transport by one overall belt: Yes

IR heating: Yes

Tension control by servo motor

Automatic up/down of the heating dryer

Friendly interface, easy for operation

LAMINATOR

Chromed double high-brightness coupling rollers.

Heating type: High accuracy intelligent heating system (internal electromagnetic cylinder), patented technology from Japan.

Electronic temperature control: Surface temperature difference < 1℃

Internal electromagnetic heating cylinder works (patented technology)

Automatic film tension control

Air Shaft locking mechanism: Yes

10 inch touch screen, friendly interface

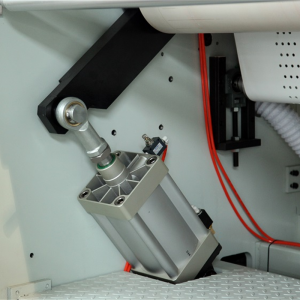

Pressure: Counter pressure roller pneumatically activated, no risk of leaking

Film slitter and re-winder

Teflon treatment on all gluing parts, greatly reducing time and difficulty of cleaning

Automatic open/close of oven, easy for cleaning and maintenance

High-efficiency drying roller and hot air circulation oven

SHEET SEPARATOR

Patented hot knife separation technology for cutting PET, Metalic or Nylon film.

BAUMER laser sensor made in Switzerland, for accurately detecting hot knife cutting position and guaranteeing clean cutting edge.

Perforating wheel: Yes

Rotary Knife: Yes

Fully automatic integrated snapping roll: Yes

Sheet blower: Yes

Optional: Double-laser automatic correction system

STACKER

Slow down unit: Yes

Pile loading: Pallet in feed Yes

Paper Height 1200mm

Pneumatic side pushers: Yes

Automatic motorized platform with auto protection function

AIR

Pressure: 6 bar or 90 psi Incoming air: 10mm diameter pipe

POWER

Voltage 380V-50 Hz

3 phases plus earth and neutral with a circuit breaker

Heating power 20Kw

Working power 45Kw

Breaker needed: 250A

SAFETY APPROVAL

CE

|

KMM-1250DW Main Commercial Part List |

|||

|

No |

Name |

Brand |

Note |

|

1 |

Industrial CPU |

BECKHOFF |

Made in Germany |

|

2 |

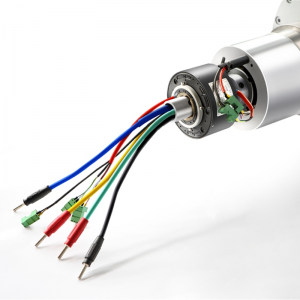

Hot knife servo motor |

BECKHOFF |

Made in Germany |

|

3 |

Hot knife servo drive |

BECKHOFF |

Made in Germany |

|

4 |

Extension module |

BECKHOFF |

Made in Germany |

|

5 |

Other servo motor and drive |

DELTA |

|

|

6 |

Sensor |

OMRON |

|

|

7 |

Proximity switch |

OMRON |

|

|

8 |

Laser Sensor |

BAUMER |

MADE IN SWITZERLAND |

|

9 |

Conveyor belt |

AMMERAAL BELTECH |

Based in Switzerland |

|

10 |

Pneumatic parts |

AIRTAC |

|

|

11 |

Bearings |

C&U |

Best brand in China |

|

12 |

Intelligent Electromagnetic Heating System |

DR |

Technology from Japan |