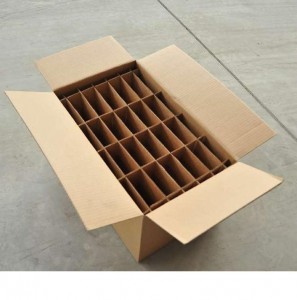

ZL-900X500 6N Automatic Partition Assembler Machine for Corrugated

I. Application and characteristics

ZL900X500 6N serious automatic partition assembler machine is optimized to be a new partition assembler devices on the basis of absorbing the advantage of equipment at home and abroad in our factory. The equipment takes the place of the traditional manual operation made, automatic complete insertion of clapboard, saving labor costs, effectively improve the production efficiency at the same time. It is the ideal packing equipment of fruit and vegetable, glass ceramic, plastic and so on.

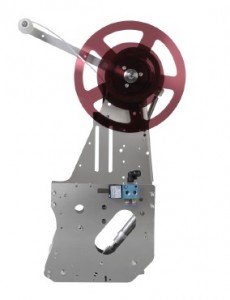

II. Structure features

1.Suitable for the auto insertion of all kinds of carton clapboard.

2.Vertical direct using vacuum adsorption feeding, landscape orientation using servo feeding , quick and accurate .

3.Longitudinal and transverse to cross the two pieces of paper at the same time.

4.Longitudinal feeding shaft adopts electric lifting .

5.Landscape orientation feeding worktable lifting adopts electric adjustment .

6.Electric adjust the clapboard height in landscape orientation .

7.Output in double work positions, high efficiency and energy saving.

8.Touch screen input control, electric to adjust the clapboard parameters .

9.Comprehensive using of pneumatic and electric control, to ensure the advancement of machine control .

10.Using compressed air storage tanks for gas centralized supply, gas supply pressure stability, enough gas source.The gas devices get the gas from the primary tracheal , independent control, no influence between each other .

11.Equipped with fault detection device, auto stop the machine when paper blocking .

III. Advantages introduction

1.Instead of traditional manual operation mode, reduce the manpower cost, high efficiency and energy saving

2.Touching screen configuration, easy operation

3.All parts is made of high quality raw materials, after precision machining equipment, long service life

4.Science advanced mechanical structure, adjust easily in short time, easy to use and maintenance .

5.Purchased components selects the high quality brand products at home and abroad, the quality is guaranteed

6.

| IV. Machine model introduction: | |

| VII. Configuration List | |||

|

S/N |

Name |

Qty |

Note |

|

1 |

Auto partition assembler |

1 set |

Output : double station Clapboard combinations: crisscross |

|

2 |

Paper feeder |

1 set |

|

|

3 |

Electric system |

1 set |

PLC, human-computer interface, Servo control |

|

Serial |

Brand |

Origin |

|

PLC |

Delta |

TaiWan |

|

servo motor |

Delta |

TaiWan |

|

touch screen |

Delta |

TaiWan |

|

electrical parts |

Schneider |

France |

|

AirTAC |

Taiwan |

|

|

Wanxin |

China |

|

|

bearing |

HRB |

China |

|

Transmission synchronous belt |

Farman |

China |

| Max speed | 8000sheets/h |

| Max speed size | 720*1040mm |

| Min sheet size | 390*540mm |

| Max printing area | 710*1040mm |

| Thickness(weight) of paper | 0.10-0.6mm |

| Feeder pile height | 1150mm |

| Delivery pile height | 1100mm |

| Overall power | 45kw |

| Overall dimensions | 9302*3400*2100mm |

| Gross weight | About 12600kg |

1.Frequency conversion stepless speed regulation; PLC control; air clutch

2.Anilox roller & chambered doctor blade adopted; coating glossy and well-distributed

3.Sliding coating system with good rigidity and enough space for operation

4.Non-stop feeder & delivery

5.Drop-down conveyor belt prevents burns and enhances security

6.UV oil temperature-controlled preheating and circulatory delivering devices; electrical pump standard and diaphragm pump for option

|

Name |

Model and function characteristics. |

| Feeder | ZMG104UV,Height: 1150mm |

| Detector | convenient operation |

| Ceramic rollers | Improve printing quality |

| Printing unit | Printing |

| Pneumatic diaphragm pump | safe, energy-saving, efficient and durable |

| UV lamp | improves the wear resistance |

| Infrared lamp | improves the wear resistance |

| UV lamp control system | wind cooling system (standard) |

| Exhaust ventilator | |

| PLC | |

| Inverter | |

| main motor | |

| The counter | |

| The contactor | |

| The button switch | |

| Pump | |

| bearing support | |

| Cylinder diameter | 400mm |

| Tank |