Machine Model: Challenger-5000 Perfect Binding Line (Full Line)

|

Machine Model: Challenger-5000 Perfect Binding Line (Full Line) |

|||

| Items |

Standard Configurations |

Q‘ty |

|

| a. | G460P/12Stations Gatherer | Including 12 gathering stations, a hand feeding station, a criss-cross delivery and a reject-gate for faulty signature. |

1 Set |

| b. | Challenger-5000 Binder | Including a touch screen control panel, 15 book clamps, 2 milling stations, a moveable spine gluing station and a moveable side gluing station, a stream cover feeding station, a nipping station and automatic lubrication system. |

1 Set |

| c. | Supertrimmer-100 Three-Knife Trimmer | Including touch screen control panel, horizontal in-feed carriage belt from the right, vertical in-feed unit, three-knife trimmer unit, gripper delivery, and discharge conveyor. |

1 Set |

| d. | SE-4 Book Stacker | Including stacking unit, book pushing unit and emergency exit. |

1 Set |

|

e. |

Conveyor |

Including 20-meter connection conveyor. |

1 Set |

The Challenger-5000 Binding System is an ideal binding solution for small to medium production runs with max. speed up to 5,000 cycles per hour. It featurs operational convenience, high productivity, flexible changeover for multiple binding methods, and excellent performance ratio.

Outstanding Features:

♦High net output at 5000 books/hour with thickness up to 50mm.

♦Position indicators provide user-friendly operation and precise adjustments.

♦Spine preparation with powerful milling motor for top-quality spine forming.

♦Rigid nipping and cover scoring stations for strong and accurate binding.

♦European imported spare parts gurantee strong and consistent performance.

♦Flexible changeover between hotmelt EVA and PUR binding method.

Configuration 1: G460P/12 Stations Gatherer

G460P gathering system is speedy, stable, convenient, efficient, and flexible. It can be used either as a stand-alone machine or connected in-line with Superbinder-7000M/ Challenger-5000 Perfect Binder.

●Reliable and non-marking signature separation thanks to the vertical gathering design.

●Touch screen allows easy operation and convenient fault analysis.

●Comprehensive quality control for miss-feed, double-feed and paper jams.

●Easy changeover between 1:1 and 1:2 production modes brings high flexibility.

●Criss-cross delivery unit and hand feeding station are offered as standard features.

●Reject gate for faulty signatures ensures non-stop production.

●Excellent quality control is enabled by the optional signature recognition system.

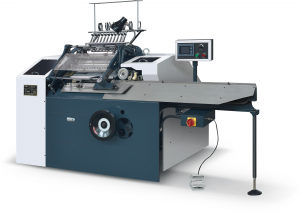

Configuration 2: Challenger-5000 Binder

The 15-clamp perfect binder Challenger-5000 is an ideal choice for small to medium production runs with speed up to 5000 cycles/hour. It features easy operation and precise change-over by position indicators.

Configuration 3: Supertrimmer-100 Three-Knife Trimmer

The Supertrimmer-100 features sturdy configurations and precise cutting accuracy with a user-friendly touch-screen control panel. This machine could be used stand alone, or connected in-line for a complete binding solution.

♦Streamlined process: feeding, positioning, pushing-in, pressing, trimming, output.

♦No book no cut control to avoid unnecessary movements

♦Cast-made machine frame for a reduced vibration and higher trimming precision.

|

One set of Supertrimmer-100 Touch screen control panelHorizontal infeed carriage belt from the right

Vertical infeed unit Three-knife trimmer unit Gripper delivery Output conveyor

|

Configuration 4: SE-4 Book Stacker

|

One set of SE-4 Book Stacker Stacking Unit. Book Emergency Exit. |

Configuration 5: Conveyor

|

20-meter connection conveyorTotal length: 20 meters.1 book emergency exit.

LCD main control. Each section of conveyor speed adjusted by ratio or separately.

|

|

Critical Parts List of Challenger-5000 Binding System |

|||

|

Item no. |

Parts Name |

Brand |

Remark |

|

1 |

PLC |

Schneider (French) |

Gatherer, Binder, Trimmer |

|

2 |

Inverter |

Schneider (French) |

Gatherer, Binder, Trimmer |

|

3 |

Touch Screen |

Schneider (French) |

Gatherer, Binder, Trimmer |

|

4 |

Power supply switch |

Schneider (French) |

Binder, Trimmer |

|

5 |

Power supply switch |

MOELLER (Germany) |

Gatherer |

|

6 |

Main motor of binder, Milling station motor |

SIEMENS (Sino- Germany joint venture) |

Binder |

|

7 |

Switching power supply |

Schneider (French) |

Gatherer |

|

8 |

Switching power supply

|

East (Sino-Japanese joint venture) |

Trimmer |

|

9 |

Photoelectric switch

|

LEUZE (Germany), P+F(Germany), OPTEX (Japan) |

Gatherer, Binder |

|

10 |

Proximity switch |

P+F(Germany) |

Gatherer, Binder, Trimmer |

|

11 |

Safety switch |

Schneider (French), Bornstein(Germany) |

Gatherer, Binder, Trimmer |

|

12 |

Buttons

|

Schneider (French), MOELLER (Germany) |

Gatherer, Binder, Trimmer |

|

13 |

Contactor |

Schneider (French) |

Gatherer, Binder, Trimmer |

|

14 |

Motor protection switch, circuit breaker |

Schneider (French) |

Gatherer, Binder, Trimmer |

|

15 |

Air pump

|

ORION (Sino-Japanese joint venture) |

Gatherer, Binder |

|

16 |

Air compressor

|

HATACHI (Sino-Japanese joint venture) |

Full Line |

|

17 |

Bearing

|

NSK/NTN (Japan), FAG (Germany), INA (Germany) |

Binder, Trimmer |

|

18 |

Chain

|

TSUBAKI(Japan), TYC(Taiwan) |

Binder, Trimmer |

|

19 |

Electromagnetic valve

|

ASCA (USA), MAC (Japan), CKD (Japan) |

Gatherer, Binder |

|

20 |

Air cylinder |

CKD (Japan) |

Gatherer, Trimmer |

Remark: The machine design and specifications are subject to change without notice.

| Technical Data | |||||||||

|

Machine Model |

G460P/8 |

G460P/12 |

G460P/16 |

G460P/20 |

G460P/24 |

|

|||

| No. of Stations |

8 |

12 |

16 |

20 |

24 |

||||

| Min. Sheet Size (a) |

196-460mm |

||||||||

| Min. Sheet Size (b) |

135-280mm |

||||||||

| In-line Max. Speed |

8000 cycles/h |

||||||||

| Off-line Max. Speed |

4800 cycles/h |

||||||||

| Power Required |

7.5kw |

9.7kw |

11.9kw |

14.1kw |

16.3kw |

||||

| Machine Weight |

3000kg |

3500kg |

4000kg |

4500kg |

5000kg |

||||

| Length of Machine |

1073mm |

13022mm |

15308mm |

17594mm |

19886mm |

||||

|

Machine Model |

Challenger-5000 |

||||||||

|

No. of Clamps |

15 |

||||||||

|

Max. Mechanical Speed |

5000 cycles/h |

||||||||

| Book Block Length (a) |

140-460mm |

||||||||

| Book Block Width (b) |

120-270mm |

||||||||

| Book Block Thickness (c) |

3-50mm |

||||||||

| Cover Length (d) |

140-470mm |

||||||||

| Cover Width (e) |

250-640mm |

||||||||

| Power Required |

55kw |

||||||||

| Machine Model |

Supertrimmer-100 |

||||||||

| Untrimmed Book Size (a*b) |

Max. 445*310mm (Off-line) |

||||||||

|

Min. 85*100mm (Off-line) |

|||||||||

|

Max. 420*285mm (In-line) |

|||||||||

|

Min. 150*100mm (In-line) |

|||||||||

| Trimmed Book Size (a*b) |

Max. 440*300mm (Off-line) |

||||||||

|

Min. 85*95 mm (Off-line) |

|||||||||

|

Max. 415*280mm (In-line) |

|||||||||

|

Min. 145*95mm (In-line) |

|||||||||

| Trim Thickness |

Max. 100 mm |

||||||||

|

Min. 10 mm |

|||||||||

| Mechanical Speed | 15-45 cycles/h | ||||||||

| Power Required | 6.45 kw | ||||||||

| Machine Weight | 4,100 kgs | ||||||||

-2-300x169.jpg)