Cambridge-12000 High-Speed Binding System (Full Line)

Cambridge12000 Binding System is JMD’s latest innovation of world leading perfect binding solution for

high production volume. This high performance perfect binding line features on outstanding binding

quality, faster speed and higher degree of automation, which makes it an ideal choice for large printing houses to improve production efficiency and to lower production cost.

♦High Productivity: Book production speed up to 10,000 books/hour can be achieved, which increases greatly the net output and cost-effectiveness.

♦Strong Stability: The whole system is designed with European top quality standards, and use high quality materials and components, which ensures a strong stability even at very fast running speed.

♦Outstanding Binding Quality: JMD’s core binding technologies integrated with advanced automatic control system creates a strong and accurate perfect binding effect.

♦High Degree of Automation: By employing servo-motor control system in the critical parts, the make-ready time is greatly shortened for different binding formats.

♦Optional PUR Binding Function: Changeover between EVA and PUR gluing application systems can be easily finished in just a few minutes.

Configuration 1: G-120/24Stations Gatherer

G-120 High-Speed Gathering Machine is to gather the folded signatures, and then feed the well-gathered book block into the perfect binder. G-120 gathering machine consists of gathering station, rejection gate, hand feeding station and other units.

●Horizontal gathering design allows fast and steady feeding of signatures.

●Comprehensive detection systems can detect the miss-feed, double-feed, jam and overload.

●1:1 and 1:2 speed change mechanism brings high efficiency.

●Hand feeding station provides convenient feeding of additional signatures.

●Gathering machine and binding machine can work standalone.

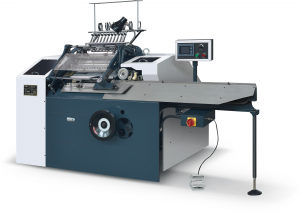

Configuration 2: Cambridge-12000 High-Speed Binder

The 28-clamp perfect binder offers simple operation and superior binding quality. Double spine gluing and double nipping process creates durable, strong binding quality with sharp spine corners.

♦High-speed and high productivity up to 10,000 cycles per hour

♦28 Siemens servo motor controlled book clamps

♦Siemens touch screen control system for easy operation

♦Dual spine gluing stations for superior binding quality

♦Easy changeover between EVA and PUR gluing application systems

♦In-lined with G460B gatherer and T-120 three knife trimmer

Configuration 3: T-120 Three-Knife Trimmer

T-120 Three-Knife Trimmer is specially designed and firmly built with European high quality standards. It can automatical finish all the processes from untrimmed books stacking, feeding, positioning, pressing, and trimming to trimmed books delivery, with max. mechanical speed of 4000 c/h.

Automatic adjustment system of T-120 Three-Knife Trimmer enables short make-ready and quick changeover. The intelligent diagnose system will provide the fault-indication, and alarm when the papameter set-up is wrong, which can maximally reduce the machine damage caused by human factor.

It can be used either as a stand-alone machine or connect in-line with Cambridge-12000 Perfect Binder.

♦High production efficiency up to 4000 c/h with excellet trimming quality.

♦High automation and short make-ready: the side gauge, front stop gauge, distance between two side knives, height of output conveyor, height of pressing station are automatically adjusted by servo motors.

♦Books of a wide range sizes can be trimmed to meet different requirements.

♦High safety operation can be guaranteed by torque limiter at book stacking unit, which can proetct the machine from accidentally overload.

| 4) Technical Data | ||||||||||||||||||||||||||||||||||

|

Machine Model |

G-120 |

|

||||||||||||||||||||||||||||||||

| No. of Stations |

24 |

|||||||||||||||||||||||||||||||||

| Sheet Size (a) |

140-450mm |

|||||||||||||||||||||||||||||||||

| Sheet Size (b) |

120-320mm |

|||||||||||||||||||||||||||||||||

| In-line Max. Speed |

10000 cycles/h |

|||||||||||||||||||||||||||||||||

| Power Required |

15kw |

|||||||||||||||||||||||||||||||||

| Machine Weight |

9545kg |

|||||||||||||||||||||||||||||||||

| Length of Machine |

21617mm |

|||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||

| Machine Model |

T-120 |

|||||||||||||||||||||||||||||||||

| Untrimmed Book Size (a*b) |

Max. 445*320mm |

|||||||||||||||||||||||||||||||||

|

Min. 140*73mm |

||||||||||||||||||||||||||||||||||

| Trimmed Book Size (a*b) |

Max. 425*300mm |

|||||||||||||||||||||||||||||||||

|

Min. 105*70mm |

||||||||||||||||||||||||||||||||||

| Trim Thickness |

Max. 60 mm |

|||||||||||||||||||||||||||||||||

|

Min. 3 mm |

||||||||||||||||||||||||||||||||||

| Mechanical Speed | 1200-4000cycles/h | |||||||||||||||||||||||||||||||||

| Power Required | 26kw | |||||||||||||||||||||||||||||||||

| Machine Weight | 4,000 kgs | |||||||||||||||||||||||||||||||||

| Machine Dimensions (L*W*H) | 1718*4941*2194mm | |||||||||||||||||||||||||||||||||

-2.jpg)

-2-300x169.jpg)

-5-300x169.jpg)

-300x168.jpg)

2-300x168.jpg)

-2.jpg)

2.jpg)