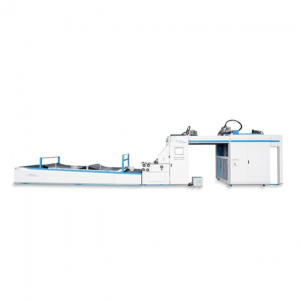

KFQ- Model Bare Frame Style High Speed Slitting Machine

| Width | 2600mm |

| Thickness of material | 50g/m2-500g/m2 (Decided according to the material) |

| Max diameter of raw material | φ1700mm |

| Max diameter of rewinding | φ1500mm |

| Width of material | 2600mm |

| The diameter of pneumatic shaft of rewinding | φ76mm (3”) |

| Rewinding shaft | 2 pcs(can rewinding with single shaft ) |

| Precision of slitting | ±0.2mm |

| Speed | 600m/min |

| Total power | 45-68kw |

| Weight | About 22000kg |

| Main color of machine body | Milky color |

| Adopts auto-photoelectric error correction | |

| Size (L*W*H) | 6500X4800X2500MM |

1, Unwinding part

1.1 Adopts casting style for machine body

1.2 Adopts hydraulic shaftless loading syestem

1.3 40kg tension magnetic powder controller and auto taper style control

1.4 With Hydraulic shaftless unwinding

1.5 Transmission guide roller: aluminum guide roller with active balance treatment

1.6 Adopts liquid press style subtense system,Error-correction precision: ±0.3mm

1.7PLC control (Siemens ),Touch screen (Made in Siemens)

2, Main machine part

●Adopts 60# high-quality casting structure

●Supported by non-gap empty steel tube

2.1 Drive and transmission structure

◆ Adopts motor and speed reducer together

◆ Adopts frequency timing system for main motor

◆ Transducer (Japan mitsubishi brand)

◆ Transmission structure: adopts vection control V6/H15KW(Coder made in Japan)

◆ Guide roller: adopts aluminum alloy guide roller with active balance treatment

◆ Aluminum guide roller:

2.2 Traction device

◆ Structure: active traction manual pressing style

◆ Pressing style is controlled by cylinder:

◆ Pressing roller: rubber roller

◆ Active roller: chrome plate steel roller

◆ Drive style: main transmission shaft will be drove by main motor, and active shaft traction will be drove by main shaft

2.3 Slitting device

◆ Circle blade device

◆ Upper knife shaft: empty steel shaft

◆ Upper round knife: can be adjusted freely.

◆ Lower knife shaft: steel shaft

◆ Lower round knife: can be adjusted by shaft cover

◆ Slitting precision: ±0.2mm

3 Rewinding device(surface and center rewinding)

◆ Structure style: double air shafts (also can use single air shafts)

◆ Adopts tile style air shaft

◆ Adopts moment motor for rewinding (60NL/set)

◆ Transmission style: by gear wheel

◆ Diameter of rewinding: Max ¢1500mm

◆ Impaction style: adopts air cylinder fixing cover structure

4 Wasted-material device

◆ Elimination style of wasted material: by blower

◆ Main motor: adopts three-phase moment motor 15 kw

5 Operation part: by PLC

◆It is composed of main motor control, tension control and others, All switch adopts schineider French

◆Main motor control: including main motor control and main controlling box

◆Tension control: unwinding tension, rewinding tension, speed.

◆Enclose with electronic metering, stop by alarm system, auto length-position.

All electrical components is made by French Schneider

Brand of main parts Brand Country

1)PLC: Siemens ,Germany

2)Touch screen: Wenview , Taiwan

3)Frequency converter: V-T , American

4)Rotary Coder for shaft : Nemicon ,Japan

5)EPC control system : Arise Taiwan

6)Electrical switch and buttons : Schneider ,French

6 Power: three-phase and four-line air switch voltage: 380V 50HZ