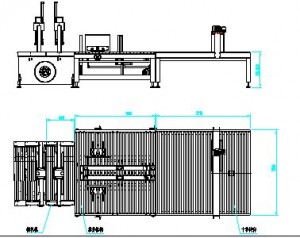

Automatic Folder Gluer for corrugated box(JHX-2600B2-2)

|

Model |

JHX-2600B2-2 |

|

Installation Area |

12000*4200mm |

|

Total Power |

14.1Kw |

|

Max. Gluing Speed |

130m/min |

|

Sheet Thickness |

A, B, C, AB |

|

Gluing Method |

Glue Wheel |

|

Gluing Width |

25/35mm |

|

Power Supply |

380V 50HZ |

When do gluing

|

Model |

JHXDX-2600B2-2 |

|

|

|

Max(mm) |

Min(mm) |

|

A |

880 |

200 |

|

B |

900 |

100 |

|

C |

880 |

200 |

|

D |

900 |

100 |

|

E |

2500 |

680 |

|

F |

900 |

300 |

|

G |

35-40 |

|

a) Key Features

●Unique separate sheet separation and registration part which can eliminate the fish tail phenomenon effectively.

●Order saving function can store the carton size in touch screen, machine will adjust automatically when the operator selected an saved order.

b) Main Features

●Patent design of 90°angle folding knife can make the carton folding precisely.

●Using motor to adjust the synchronous belts, easy operation and reduce change time.

●

Feeding Unit:

a) Adopt high quality rubber vacuum belt, stocking and automatic input to ensure the efficiency of feeding.

b) Special design makes the adjustment simply, quickly and precisely. Pneumatic side regulation, paper feed baffle and belt are separately operated, which make the order change easy.

Creasing wheel

There is a creasing wheel at the sticking point, and the folding effect is better.

Gluing Unit:

a) The gluing width is 25mm/35 mm-gluing from bottom side.

b) The glue box can be moved left or right according to the requirement of the corrugated board.

c) The gluing amount can be adjusted.

d) The glue box is made of stainless steel-big contain and easy for cleaning.

e) The electrical control system makes nail stitching more precise.

f) Automatic nail feeding device, four sensors detecting the nail shortage break.

Pressure roller

The seven pressure rollers from big to small, it is not easy to crush the paper and make sure the good folding effect.

Folding Unit

a) It uses high friction belt. The folding speed is controlled by frequency converter which can be controlled separately and synchronized with the main motor.

b) Motor driven for order change adjustment-fast and convenient.

c) Re-creasing roller, re-creasing knife, side roller and flapping plate can eliminate the fish tail effectively. The re-creasing knife adopts new design and structure which makes the carton folding straight and perfect.

d) The top strengthen parts adopt liner slide rail and pneumatic lock device, it makes the machine running stably in high speed which can ensure the folding precisely.

Diagonal pressure roller

There is a set of diagonal pressure rollers at the back of left folding and right folding which can achieve a 90 degree folding.

Sheet Separation and Registration Unit

a) Our unique design of sheet side lay and speed disparity unit can connect with other automatic folder gluer.

b) When choose stitching mode, there has two servo motors control the sheet aligning actions, secondary compensation and correction system eliminates fish tails phenomenon.

Automatic Adjusting Function

Re-design and structure of support wheels, electric control and motor driving make the adjustment fast and convenient, suit for different thickness corrugated board.

Take the top part of corrugated sheet as the base line getting an accurate positioning and reducing the fish tail problem greatly.

Motor and encoder make the adjustment easy and convenient, the operator can save the sheet data though touch screen.

Stitching Unit

1.Adopts Synchronous belt drive, PLC control system, touch screen adjustment, convenient, fast and accurate.

2.The swing style stitching head with the features of less power consumption, faster speed and high stability can effectively enhance the product quality.

3.One button control the gluing mode and stitching mode exchange, all adjustment controlled by electric motor.

4.The nail pitch and stitching head up and down are controlled by electric motors. The cut-off knife adopts cemented carbide material, long service life.

5.The nail shape can be adjusted as sheet requirement.

Stacking and Counting Unit

a) The Flapping Plate can help to reduce the fish tail phenomenon when gluing.

b) The pile number can be set at 10, 15, 20 and 25.

Scientific and reasonable mechanical structure, reliable quality electrical elements makes the machine free of trouble.

1.Installation areas: 12000×4200mm

2.Training, installation and debugging

a)Seller in charge of installation, debugging and training in the buyer's factory. However the days used should be generally no more than seven days

b)The buyer should try to help as much as they can while the supplier’s engineer is debugging the machine by providing enough workers, powers, tools and some necessary documents or papers.

a) Electric Part:

|

Name |

Brand |

Specification |

Model |

Quantity |

|

Frequency converter |

Invoance |

|

MD300 |

1 |

|

Power |

Taiwan Mean Well |

S-150-24 |

NES-150-24 |

1 |

|

Contactor |

French Schneider |

LC1-D0910M5C |

LCE0910M5N |

5 |

|

Control button |

Shanghai Tianyi |

Green button |

LA42P-10 |

13 |

|

Red button |

LA42PD-01 |

1 |

||

|

Green lamp |

LA42PD-10/DC 24V |

4 |

||

|

Red lamp |

LA42PD-01/DC 24V |

4 |

||

|

Yellow lamp |

LA42PD-20/DC 24V |

1 |

||

|

Control knob |

Fuji |

|

LA42J-01 |

1 |

|

Photoelectric switch |

OPTEX |

|

BTS-10N |

1 |

|

Air switch |

Delixi |

DZ47 |

E3F3-D11 |

1 |

|

Touch screen |

Hitech |

10inch |

PWS5610T-SB |

1 |

|

PLC |

Invoance |

|

|

|

b) Main Mechanical Parts:

|

|

Name |

Brand |

Quantity |

|

1 |

Feeding belt(A) |

Bailite |

6 |

|

2 |

Receiving belt(C) |

Forbo-siegling |

19 |

|

3 |

Conveyor belt(B) |

Forbo-siegling |

13 |

|

4 |

Air fan |

Hengshui(Licen) |

1 |

|

5 |

Main Motor |

Simens(beide) |

1 |

|

6 |

Gear Motor |

Zhejiang |

6 |

-Sample-300x260.jpg)