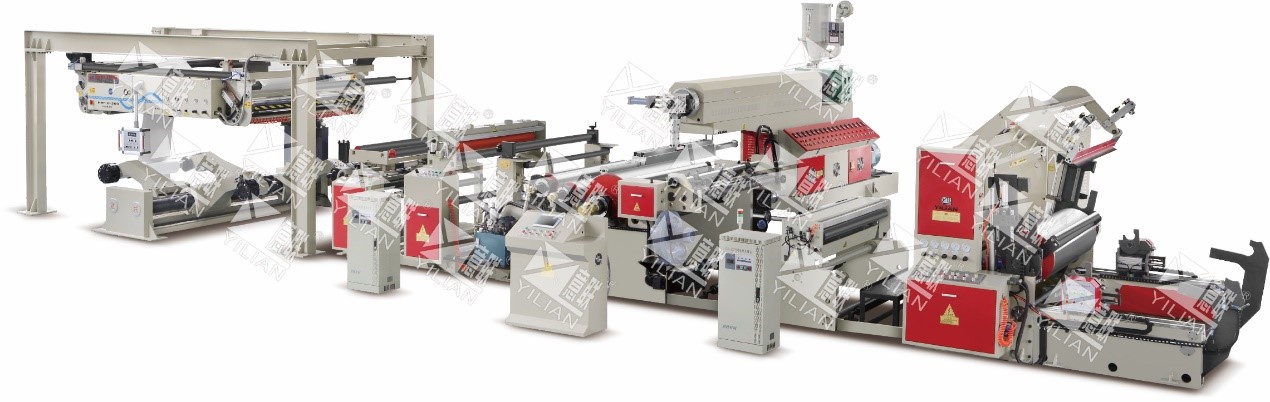

WSFM1300C Automatic Paper PE Extrusion Coating Machine

| Suit laminating resin | LDPE、PP etc |

| Suit base material | paper(80—400g/m²) |

| Max mechanical speed | 300m/min( working speed depends on the coating thickness, width) |

| Coating width | 600—1200,guide roller width:1300mm |

| Coating thickness | 0.008—0.05mm (Single screw) |

| Coating thickness error | ≤±5% |

| Auto tension setting range | 3—100kg full margin |

| Max extruder quantity | 250 kg/h |

| Compound cooling roller | ∅800×1300 |

| Screw Diameter | ∅110mm ratio35:1 |

| Max unwind diameter | ∅1600mm |

| Max rewind diameter | ∅1600mm |

| Unwind paper core dia :3″6″ and Rewind paper core diameter:3″6″ | |

| Extruder is drove by 45kw | |

| Total power | about 200 Kw |

| Machine weight | about 39000kg |

| Outside dimension | 16110 mm×10500 mm ×3800 mm |

| Machine body color | Grey and Red |

1. Unwind part (with PLC, servo unwinding)

1.1 Unwind frame

Structure: Hydraulic shaft-less unwinding frame

The BA series splicer forms an integral part of the lamination line and is installed over the roll stand underneath the bridge structure. It allows the continuity in running of the existing paper roll to the next paper roll without stoppage of the production.

Within the splicer side frames are 2 movable splicing head and a movable central support section. Above it are 2 nip rolls.

The capstan roll, reverse idler roll and double dancer system form the paper accumulation section which is able to accumulate paper up to 4 times the length of the splicer.

The machine is operated through the operation panel on the machine

Paper linking speed Max.300m/min

a)when paper strength above 0.45KG/mm,max. 300m/min;

b)when paper strength above 0.4KG/mm,max. 250m/min;;

c)when paper strength above 0.35KG/mm,max. 150m/min;;;

Paper width

Max. 1200mm

Min. 500mm

Speed CE-300

Max. 300m/min

Pneumatic data

Set pressure 6.5 bar

Min. pressure 6 bar

Model CE-300

Power 3.2kVA, 380VAC/50Hz/20A

Control voltage 12VDC/24VDC

1.1.1 Independent hydraulic shaft spindle clamp arm type double work-station unwinding,without air shaft ,hydraulic loading ,save the cost of loading mechanical structure. Automatic AB shaft auto reel alternation, less waste of material.

1.1.2 Max. unwinding dia.:¢1600mm

1.1.3 Auto tension setting range :3—70kg full margin

1.1.4 tension precision:± 0.2kg

1.1.5 paper core:3” 6”

1.1.6 Tension control system: shaft type of tension detector by precision potentiometer detection tension, the centralized control of the programmable PLC

1.1.7 Drive control system:PIH cylinder braking, the rotary encoder feedback speedily, precision pressure regulating valve closed loop control, programmable controller PLC centralized control

1.1.8 Tension setting :By the precision pressure regulating valve setting

1.2 Storing type of automatic picking, cutting device

1.2.1 Storing driven by pneumatic motor buffer, ensure stable tension when picking paper.

1.2.2 separate cutting structure

1.2.3 PLC auto calculate new shaft rotary speed, and keep speed with main line speed

1.2.4 Receive material press roller, cutter broken material .tension control change, reset all can finish automatically

1.2.5 Roller change pre alarm,: work diameter when reach 150mm.,machine will alarm

1.3 Rectifying control: photoelectric putter rectifying control system (bst structure)

2. Corona (Yilian customized)

Corona treatment power :20 kw

3. Hydraulic lamination unit:

3.1 Three rollers laminating compound structure, back press roller, can make compound roller bear strength even, compound firm.

3.2 Stripping of silicon rubber roller: compound product is easy to peer off from cooling roller, Hydraulic can press tightly.

3.3 The curved roll film flattening structure,: can make film rapid deployment

3.4 Compound feed material adjust roller can overcome film material thickness uneven and so on weakness

3.5 High pressure blower sucks scrap edge quickly.

3.6 Compound outlet cutter roller

3.7 Compound roller is driven by motor dependently

3.8 Compound roller driven motor is controlled by Japan frequency controller

Spec:

(1)compound roller:¢ 800 × 1300mm 1pcs

(2)rubber roller:¢ 260 × 1300mm 1pcs

(3)press roller:¢ 300 × 1300 mm 1pcs

(4)compounding oil cylinder:¢63 × 150 2pcs

(5)peel off roller:¢130 × 1300 1pcs

(6)11KWmotor(SHANGHAI) 1set

(7)11KW Frequency converter (JAPAN YASKAWA)

(8)rotate connector:(2.5"2 1.25"4)

4. Extruder (auto height adjusting )

4.1 Screw diameter:¢ 110,Max extruder about :250kg/h (Japanese technology )

4.2 T-die( Taiwan GMA)

4.2.1 Mold width:1400mm

4.2.2 Mold effective width:500-1200mm

4.2.3 Mold lip gap:0.8mm, coating thickness: 0.008—0.05mm

4.2.4 Coating thickness error:≤±5%

4.2.5 Electric heating tube inside heating, heating high effective, temperature increase quickly

4.2.6 Totally enclosed passage, Stuffing width adjustment

4.3 Rapid change network devices

4.4 Front and back walking, can automatically lift Trolley, lift range :0-100mm

4.5 Mould 7 areas temperature control. Screw barrel 8 section temperature control. connector 2 area temperature control adopts Infrared heating units.

4.6 Big power Reduction gear box, HARD TOOTH (Guo tai guo mao)

4.7 Digital temperature controller automatic temperature control

Main parts:

(1) 45kw AC motor (SHANGHAI)

(2) 45KW frequency converter (JAPAN YASKAWA)

(3) Digital temperature controller 18pcs

(4) 1.5KW walking motor

5.Pneumatic Round knife trimming device

5.1 Trapezoidal screw transverse adjusting device, change the cutting width of paper

5.2 Pneumatic Pressure cutter

5.3 5.5kw high pressure edge absorb

6.Rewinding Unit :3D heavy duty structure

6.1 Rewinding Frame:

6.1.1 Friction type electric double stations rewinding machine, high-speed automatic cutting and picking finished material, automatic unloading.

6.1.2 Max. rewinding diameter:¢ 1600 mm

6.1.3 roll-over speed:1r/min

6.1.4 tension:3-70kg

6.1.5 Tension precision:± 0.2kg

6.1.6 paper core: 3″ 6″

6.1.7 Tension Control System: The cylinder cushion floats the floating roller type structure, the tension is detected by the precision potentiometer, and the programmable controller PLC centrally controls the tension. (Japan SMC low friction cylinder) 1 set

6.1.8 Drive Control System: 11KW motor drive, rotary encoder speed feedback, Senlan AC inverter dual closed-loop control, programmable controller PLC centralized control. 1 set

6.1.9 Constant Tension Setting: Precision Pressure Regulator Setting (Japan SMC)

6.1.10 Taper tension setting: arbitrarily set by computer screen, PLC control, conversion by electric/air ratio (Japan SMC)

6.2 Automatic Feeding and Cutting Device

6.2.1 Splicing Support Rollers are controlled by a PLC to drive the motor to hold the material away from the rubbing roller

6.2.2 Hydraulic Independent Cutter Mechanism

6.2.3 PLC automatic calculation of the picking process, the replacement of the volume is completed with a key

6.2.4 Function of Supporting Roller, Cutting Material, Reset, etc. Automatically Completed

6.2.5 Specifications

(1) Friction roller: ¢700x1300mm 1 bar

(2) Winding motor: 11KW (Shanghai Lichao) 1 set

(3) Rolling down gear box: hardened surface helical gear reducer (Thailand Mau)

(4) Inverter: 11KW (Japan Yaskawa) 1 set

(5) Support roller gear box: 1 set of force

(6) Speed reducer: hard tooth 1 set of force

(7) Rolling walking speed reducer: 1 set of force

(8) Discharging hydraulic station

7.Auto air shaft puller

8.Drive Section

8.1 Main motor, transmission belt adopts synchronous belt

8.2 Compounding, rewinding and unwinding motor: Drive belt adopt arc gear, chain and synchronous belt transmission

8.3 Main drive gear box: Sealing oil-immersed helical gear, Line helical gear transmission structure

9.Control Unit

Independent electrical cabinet, centralized control, the composite location with centralized control cabinet operation. Machine automation system using a set of PLC (hollsys) device with high processing ability, and the man-machine dialogue signals using network communication between the interface. PLC, extrusion unit, man-machine dialogue interface between driving system and constitute an integrated automatic control system. For any parameters can be set, with automatic calculation, memory, detection, alarm, etc. Can the tension of visual display device, speed, coating thickness, speed and different working condition.

10. others

11.1 Guide Roller:Hard anodization of aluminum alloy guide roll, the movement process

11.2 Low voltage apparatus for France Schneider, omron Japan, etc.

11.parts brand

11.1 PLC(Beijing Hollysys)

11.2 Touch screen(TAIWAN)

11.3 frequency converter:Japan Yaskawa

11.4 Main motor: SHANGHAI

11.5 low friction cylinder(Japan SMC)

11.6 AC CONTACTOR(Schneider)

11.7 button(Schneider)

11. Static mixer(Taiwan)

11.9 cylinder pressure regulating valve(Taiwan)

11.10 Magnetic exchange valve(Taiwan)

11.11 precision pressure regulating valve(SMC)

12.Customer self provides facilities

12.1 Equipment space and foundation

12.2 Facilities supply for Machine electrical cabinet

12.3 Water supply to the machine facilities in and out of the gate (the buyer prepares the water chiller)

12.4 Gas supply to the machine set in and out of the stomatal

12.5 Exhaust pipe and fan

12.6 Collect, loading and unloading of base material the finished tool

12.7 Other facilities not listed in contract

13. Spare parts list:

| No. | Name | Spec. |

| 1 | Thermocouple | 3M/4M/5M |

| 2 | Temperature controller | Omron |

| 3 | Micro-regulating valve | 4V210-08 |

| 4 | Micro-regulating valve | 4V310-10 |

| 5 | proximity switch | 1750 |

| 6 | Solid relay | 150A和75A |

| 7 | travel switch | 8108 |

| 10 | heating unit | ϕ90*150mm,700W |

| 11 | heating unit | ϕ350*100mm,1.7KW |

| 12 | heating unit | 242*218mm,1.7KW |

| 13 | heating unit | 218*218mm,1KW |

| 14 | heating unit | 218*120mm,800W |

| 15 | Schneider button | ZB2BWM51C/41C/31C |

| 16 | air cock | |

| 17 | High temperature tape | 50mm*33m |

| 18 | telflon tape | |

| 19 | Corona roller cover | 200*1300mm |

| 20 | Copper sheet | |

| 21 | screen filter | |

| 22 | Circulate slits | 150*80*2.5 |

| 23 | pneumatic connector | |

| 24 | air gun | |

| 25 | water joint | 80A和40A |

| 27 | screws and others | |

| 28 | drag chain | |

| 29 | tool box |

Main parts and picture:

Unwinder(Auto splicer) → web guiding → Corona treater → Extrusion and compounding part Edge Trimming → Rewinding