RB420B Moetsi oa Lebokose le Otlolohileng

| RB420B Moetsi oa mabokose a thata ka ho iketsa | |||

| 1 | Boholo ba pampiri(A×B) | Amin | 100mm |

| Amax | 580 limilimithara | ||

| Bmin | 200mm | ||

| Bmax | 800 limilimithara | ||

| 2 | Botenya ba pampiri | 100-200g/m2 | |

| 3 | Botenya ba kareteboard(T) | 0.8-3 limilimithara | |

| 4 | Sehlahisoa (lebokose) se felileng(L×W×H) | L×W Min | 100 × 50 limilimithara |

| L×W Max | 420 × 320 limilimithara | ||

| H Min. | 12 | ||

| H Max. | 120 limilimithara | ||

| 5 | Boholo ba pampiri e phuthetsoeng (R) | Rmin | 10 limilimithara |

| Rmax | 35 limilimithara | ||

| 6 | Nepahalo | ± 0.50 limilimithara | |

| 7 | Lebelo la tlhahiso | ≦28sheets/min | |

| 8 | Matla a motlakase | 8kw/380v 3mohato | |

| 9 | Matla a heater | 6kw | |

| 10 | Phepelo ea Moea | 10L/min 0.6Mpa | |

| 11 | Boima ba mochini | 2900kg | |

| 12 | Boemo ba mochini | L7000×W4100×H2500mm | |

1. Boholo le boholo bo nyane ba mabokose bo tlas'a tsa pampiri le boleng ba pampiri.

2. Matla a tlhahiso ke mabokose a 28 ka motsotso. Empa lebelo la mochine le itšetlehile ka boholo ba mabokose.

3. Ha re fane ka compressor ea moea.

Likamano tse tšoanang pakeng tsa parameter:

W+2H-4T≤C(Max) L+2H-4T≤D(Boholo)

A(Min)≤W+2H+2T+2R≤A(Max) B(Min)≤L+2H+2T+2R≤B(Max)

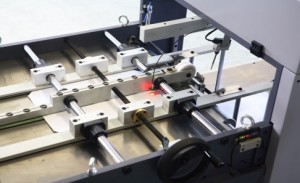

1. Mofani oa mochine ona o amohela mokhoa oa ho fepa ka morao-push, o laoloang ka pneumatically, 'me sebopeho sa oona se bonolo ebile se utloahala.

2. Bophara pakeng tsa stacker le tafoleng ea ho fepa e fetoloa concentrically bohareng. Opereishene e bonolo haholo ntle le mamello.

3. Sekoti se secha se entsoeng ka koporo se sebelisana le rolara ka mokhoa o tsitsitseng haholoanyane, ka katleho ho qoba ho phunya pampiri. 'Me scraper ea koporo e tšoarella ho feta.

4. Adopt imported ultrasonic double paper tester, e nang le ts'ebetso e bonolo, e ka thibelang likotoana tse peli tsa pampiri ho kena mochine ka nako e le 'ngoe.

5. Ho potoloha ka mokhoa o itekanetseng, ho kopanya le tsamaiso ea gluing bakeng sa sekhomaretsi se chesang se chesang. (Sesebelisoa sa boikhethelo: mitha ea viscosity ea glue)

6. Theipi ea pampiri e qhibilihang e chesang e fetisang, e sehang, 'me e qetelle e khomaretse lebokose le ka hare la quad stayer (li-angles tse 'nè) tsa khateboto ka mokhoa o le mong.

7. Fene e hulang ka vacuum tlas'a lebanta la conveyer e ka etsa hore pampiri e se ke ea kheloha.

8. Lebokose le ka hare la pampiri le khateboto le sebelisa sesebelisoa sa hydraulic rectifying ho bona hantle.

9. Sephutheloana se ka lula se phuthela, sa phutha litsebe le mahlakoreng a pampiri 'me sa theha ka mokhoa o le mong.

10. Mochine oohle o sebelisa PLC, tsamaiso ea ho latela photoelectric le HMI ho iketsetsa mabokose ka mokhoa o le mong.

11. E ka hlahloba mathata le alamo ka tsela e nepahetseng.