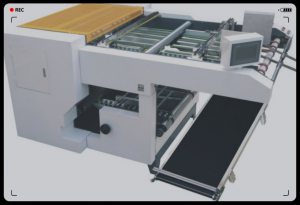

K19 – Smart board cutter

1、 The whole tray of boards is fed automatically.

2、 The long-bar board is automatically conveyed to the horizontal cutting after the first cutting is completed;

3、 After the second cutting is completed, the finished products are stacked into the whole tray;

4、 The scraps are automatically discharged and concentrated to an outlet to convenient scraps disposal;

5、 Simple and user-friendly operation process to reduce production process.

| Original board size | Width | Min. 600mm; Max. 1400mm |

| Length | Min. 700mm; Max. 1400mm | |

| Finished size | Width | Min. 85mm; Max.1380mm |

| Length | Min. 150mm; Max. 480mm | |

| Board thickness | 1-4mm | |

| Machine speed | Capacity of the board feeder | Max. 40 sheets/min |

| Capacity of the strip feeder | Max. 180 cycles/min | |

| Machine Power | 11kw | |

| Machine dimensions (L*W*H) | 9800*3200*1900mm | |

Net production is subject to sizes, materials etc.

1. Ground requirement:

The machine should be installed on a flat and sturdy floor to ensure sufficient grounding capacity, the load on the ground is 500KG/M^2 and adequate operation and maintenance space around the machine.

2. Environmental conditions:

l Keep away from oil and gas, chemicals, acids, alkalis and explosives or flammables

l Avoid adjacent to machines that generate vibration and high frequency electromagnetic

3. Material condition:

Cloth and cardboard must be kept flat and the necessary moisture and air-proof measures should be taken.

4. Power requirement:

380V/50HZ/3P. (Special circumstances need to be customized, can be explained in advance, such as: 220V, 415V and other countries voltage)

5. Air supply requirement:

Not less than 0.5Mpa. Poor air quality is the most important cause of failure of the pneumatic system. It will greatly reduce the reliability and service life of the pneumatic system. The loss caused by this will greatly exceed the cost and maintenance cost of the air supply treatment device. Air supply processing system and its components are very important.

6. Staffing:

In order to ensure the safety of human and machine, and to fully exert its performance, reduce faults and prolong the service life, it is necessary to have 1 people who are dedicated, capable and have certain mechanical equipment operation and maintenance capabilities.