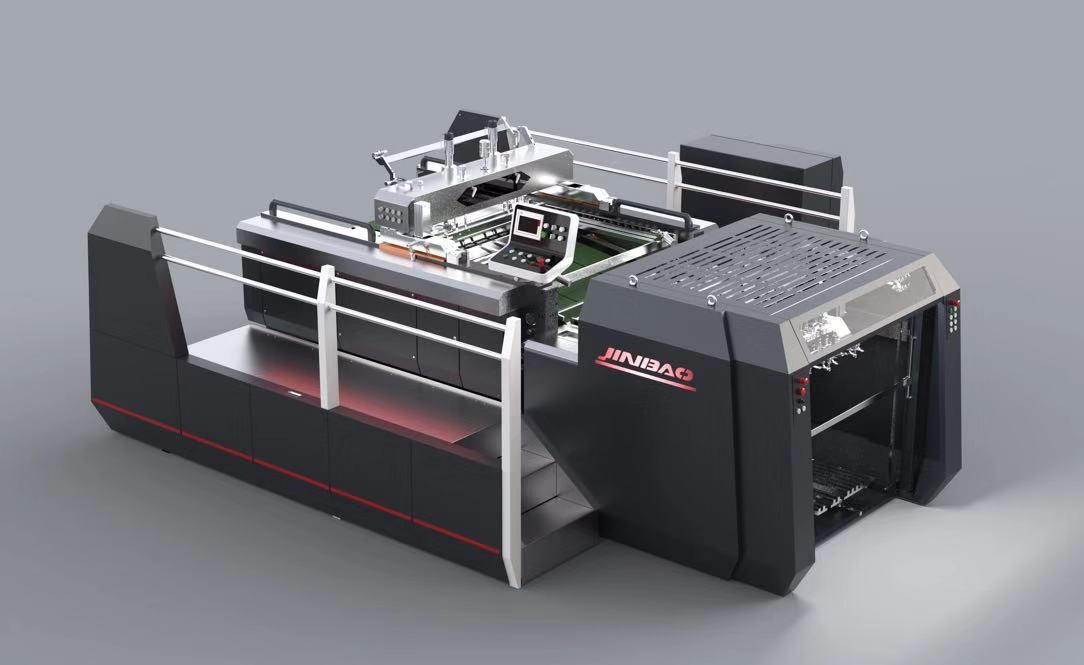

JB-145AS Servo Motor Controlled Automatic Stop Cylinder Screen-Printing Machine

It is a new type of intelligent screen printing machine independently developed and designed by our company with completely independent intellectual property rights. It has three invention patents and five utility model patents. The speed of full-size printing can be up to 3000 pieces / hour under the requirement of ensuring the quality of printing products. It is the best choice for paper and plastic packaging, ceramic and cellophane, textile transfer, metal signs, plastic film switches, electronic and electrical components and other industries.

The machine abandons the traditional single power source belt drive shaft, gearbox and chain mode, uses multiple servo motors to drive feeder, conveying, roller and mesh frame respectively, ensures the synchronization of several functional units through automatic control, not only eliminates a large number of mechanical transmission parts, but also greatly improves the rigidity of printing machinery, and reduces the errors caused by mechanical transmission device Poor, improve the printing quality and mechanical efficiency, improve the automation level of the production process, improve the working conditions of the environment.

|

|

JB-145AS |

|

Max.sheet size |

1460×1060㎜² |

|

Min.sheet size |

700×460㎜² |

|

Max.printing size |

1450×1050㎜² |

|

Frame size |

1720×1450 mm² |

|

Thickness of sheet |

108-420 g/m² |

|

Border |

|

|

Printing speed |

400-3000sheet/h |

|

Installation power |

3P 380V 50Hz 25.83Kw |

|

Total weight |

About 6500㎏ |

|

Overall size |

5300×4000×2090㎜³ |

1. Paper feeding feeder: offset Feeder head, higher speed, reliability and stability.

It has strong adaptability to the thickness of printed parts, and ensures smooth paper feeding at high speed;

The paper feeder can choose by itself and switch single sheet or laminated paper by one button.

2. Paper feeding table:

The stainless steel paper feeding table can effectively prevent the back of substrate from being scratched, and reduce the static friction between the table and substrate;

With vacuum adsorption at the bottom of the table, with the structure of pushing paper and pressing paper on the table, to ensure the smooth transportation of various materials;

When a single sheet of paper is fed, the conveyor belt slows down at the right time to ensure that the substrate is stable and in place at high speed.

3. Pneumatic side gauge:

The downward suction vacuum side pull gauge will not cause white and dirty paper and text marks.

One body variable push gauge type, one key switch, start and control push gauge pull gauge conversion.

Push pull positioning is accurate, positioning stroke is long, positioning speed is fast, and adjustment is convenient. The photoelectric detection system can monitor the position of printed parts in real time and reduce the rate of printing waste.

4. Shaftless system: traditional single power source of main drive with multiple drive modes

Using synchronous drive technology, the transmission shaft, gearbox and other mechanical devices are removed, and multiple servo motors are used to follow the virtual electronic spindle. A large number of mechanical transmission parts have been eliminated.

Noise reduction: the traditional main shaft and gearbox are discarded, the moving parts are reduced, the mechanical structure is simplified, and the components generating mechanical vibration are reduced, so the noise is greatly reduced in the operation process..

5. Heavy pneumatic scraping system: comprehensive application of electrical, pneumatic, hydraulic technology, automatic control of scraping action;

Start and end points can be set independently.

The whole process pressure is balanced and stable.

After grinding the scraper or replacing it with a new one, press one key to set and restore the previous printing pressure position.

It completely eliminates the disadvantages of cam mechanical control of squeegee action and ensures that the ink layer and clarity of the image are stable under any printing volume and printing speed.

6. Screen separation function:

The screen is separated by electric control to expose the whole conveying table and roller, so as to facilitate the registration of printing parts and the adjustment of feeding materials; at the same time, the cleaning of roller and screen is safer and faster.

7. Electric screen fine-tuning system, remote electric screen three-axis adjustment, direct input adjustment stroke, one step adjustment in place, convenient and practical.

8. Automatic oiling and lubricating system can reduce chain pulling and noise, and ensure operation accuracy and stability.

Automatic take-off set of screen press and semi-automatic screen printing press are used together, the finished products are caught up and taken out from the printing plate by manipulator and suction mouth, and delivery to next process(drying、solidifying or collecting).It can not only save the manpower, but also improve the using efficiency of the semi-automatic machine. It is fit for screen printing with soft materials, such as paper.

|

Item |

Instruction |

|||

|

1 |

Feeder |

|

||

|

|

● |

Rear pick up offset version feeder head |

Four sucking four delivery, with pre-position correction |

standard |

|

● |

Double mode paper feeding mode |

single sheet (variable speed paper feeding) or overlapping (uniform speed paper feeding) |

standard |

|

|

● |

Fast switching of paper feeding mode |

one key switching |

standard |

|

|

● |

Photoelectric double detection |

standard |

||

|

● |

Ultrasonic double sheet detection |

can only be used for single sheet paper feeding mode |

optional |

|

|

● |

One key to change the size of the paper |

the feeder head and the side guange stop paper in place quickly and automatically |

standard |

|

|

● |

Safety limited for feeder lifting |

standard |

||

|

● |

Standard configuration of non-stop system |

standard |

||

|

● |

Pre-loading |

stack printing materials in advance, reduce stacking time and improve work efficiency |

optional |

|

|

● |

Static electricity elimination device |

can reduce the static electricity on the material surface and improve the printing effect |

optional |

|

|

● |

photoelectric detection for paper shortage of paper feeding table |

standard |

||

|

2 |

Paper conveying and alignment front-lay and side-lay |

|

||

|

|

● |

paper conveying system with vacuum |

standard |

|

|

● |

double side downward suction air pull gauge |

to avoid paper front pull. |

Standard |

|

|

● |

Double side mechanical push gauge |

thick paper printing |

Standard |

|

|

● |

pull gauge / push gauge switch |

one key switch |

Standard |

|

|

● |

paper in place photoelectric detection |

side gauge in place detection and front gauge in place detection |

Standard |

|

|

● |

One key to change paper size; one key preset |

side gauge / feed brush wheel fast and automatically in place |

Standard |

|

|

3 |

Printing cylinder |

|

||

|

|

● |

Frame type lightweight roller structure |

Small inertia, stable operation |

Standard |

|

● |

adsorption printing and blowing stripping device |

Standard |

||

|

● |

anti rebound device of thick paper |

Standard |

||

|

4 |

Printing Framework |

|

||

|

|

● |

Three way electric screen fine adjustment |

Three way adjustment of remote electric screen |

Standard |

|

● |

Non-stop vertical and horizontal printing plate calibration |

Standard |

||

|

● |

automatic compensation for printing length shrinkage and extension |

Automatic compensation for the change of sheet length caused by the previous printing process |

Standard |

|

|

● |

pneumatic locking device |

Standard |

||

|

● |

the frame moves independently and disengages from the device |

Standard |

||

|

5 |

Pneumatic printing knife system |

|

||

|

|

● |

Automatic constant pressure and automatic adjustment of printing knife |

Keep printing pressure constant and improve printing quality |

Standard |

|

● |

Fast and automatic clamping of printing knife and ink returning knife |

The clamping force of the printing knife is even, which is convenient to replace the printing knife (squeegee) |

Standard |

|

|

● |

intelligent lifting up and down |

According to the printing conditions, set the position of the knife / knife, extend the life of the rubber scraper and the mesh, and reduce the ink waste |

Standard |

|

|

● |

ink drop device |

Standard |

||

|

6 |

Others |

|

||

|

|

● |

pneumatic lifting system for paper board |

Standard |

|

|

● |

automatic lubrication system |

Standard |

||

|

● |

touch screen human machine control |

Standard |

||

|

● |

safety protection grating |

Increase safety factor to ensure personal safety of operators |

optional |

|

|

● |

safety guard |

Increase safety factor and reduce the influence of dust on Printing |

optional |

|

|

|

● |

Automatic ink supply |

Supply ink automatic |

optional |

|

No. |

Item |

Qty |

Brand |

Remark |

|

1 |

Feeder drive servo motor |

1 |

Baumueller |

Germany |

|

2 |

Feed conveying servo motor |

1 |

Baumueller |

Germany |

|

3 |

Frame drive servo motor |

1 |

Baumueller |

Germany |

|

4 |

Cylinder drive servo motor |

1 |

Baumueller |

Germany |

|

5 |

Feeder main lifting motor |

1 |

CHENGBANG |

China Taiwan |

|

6 |

Feeder auxiliary lifting motor |

1 |

CHENGBANG |

China Taiwan |

|

7 |

Paper feed compound pump |

1 |

BECKER |

Germany |

|

8 |

Paper feed fan |

1 |

LINGGE |

China Zhejiang |

|

9 |

Paper discharge fan |

1 |

LINGGE |

China Zhejiang |

|

10 |

Output conveying motor |

1 |

CHENGBANG |

China Taiwan |

|

11 |

Printing knife head fine tuning motor |

2 |

Dunkermotoren |

Germany |

|

12 |

Pull gauge / screen stepper motor |

3 |

MBYS |

China Shenzhen |

|

13 |

Feeder regulating stepping motor |

4 |

MBYS |

China Shenzhen |

|

14 |

Motion controller (PLC) |

1 |

Baumueller |

Germany |

|

15 |

Controller expansion module |

18 |

Baumueller |

Germany |

|

16 |

Servo parameter module |

3 |

Baumueller |

Germany |

|

17 |

Power supply / filter / reactance module |

Each one |

Baumueller |

Germany |

|

18 |

Paper output conveying frequency converter |

1 |

Mitsubishi |

Japan |

|

19 |

Touch screen |

1 |

OMRON |

Japan |

|

20 |

AC contactor |

9 |

Eaton Muller |

Germany |

|

21 |

Motor protector |

5 |

Eaton Muller |

Germany |

|

22 |

Circuit breaker |

4 |

Eaton Muller |

Germany |

|

23 |

Press / knob switch |

58 |

Eaton Muller |

Germany |

|

24 |

Light lotus micro relay |

13 |

Fender |

Italy |

|

25 |

Micro relay |

6 |

Fender |

Italy |

|

26 |

optical fibre sensor |

8 |

OMRON |

Japan |

|

27 |

Induction switch |

12 |

OMRON |

Japan |

|

28 |

Induction switch |

8 |

IFM |

Germany |

|

29 |

Solenoid valve |

7 |

Foster |

Germany |

|

30 |

Cylinder |

6 |

Foster |

Germany |

|

31 |

Cylinder |

12 |

SMC |

Japan |

|

32 |

Solenoid valve |

9 |

SMC |

Japan |

|

33 |

Autolube pump |

1 |

SHENGXIANG |

China Tongxiang |

|

34 |

Printing guide / slide |

3sets |

THK |

Japan |