Consummables

UV, LED inks supplied are popular for our turnkey cases, in compliance with FDA regulation. We offer ink with all categories of regular and spot colors at your demand.

Blanket size is subject to specific format of your printing machine varied by brands of presses. Normal blanket size for 45” press is 1175×1135×1.95mm

Prebaked PS plate is highly recommended to save make-ready. PS plate size is normally 1160 ×1040×0.3mm for 45’’ metal press, 1040×1100×0.3mm for refurbished smaller press. We are able to offer customized sizes varied by brands of presses.

4.1 Classic Type of PS Plate Making Machine

Features

Latest model of conventional plate making

Computerized operation

Data storage

Second-time exposure

Light-flux calculation

Higher efficiency, stability and durability

Budget and cost-efficiency solution

Suitable for various types of plates such as PS plate, PVA plate and etc..

Benefits of the Line to the End-user:

Economic choice

Flexible solutions as per customer budgets

Equipment specifications:

| Elite1400 Plate Making Machine | |

| Max. plate making area | 1100×1300mm |

| Vacuum speed | 1L/S |

| Vacuum range | 0-0.08MPa |

| Light evenness | ≥95% |

| Power supply | 3KW 220V/380V |

| Machine Dimension | 1500×1350×1300mm |

| Weight | 400kg |

| Elite1250 Automatic Plate Developing Machine | |

| Max. developing width | 1200 mm |

| Min. developing length | 360 |

| Developing thickness | 0.15-0.3mm |

| Developing speed | 20-80s |

| Developing temperature | 20-40ºC (adjustable) |

| Drying temperature | 40-90 ºC (adjustable) |

| Developing solution volume | 35L |

| Glue volume | 5L |

| Power supply | 220V 20A |

| Weight | 500kg |

| Machine dimension | 1500×1600×1150mm |

Line Working Environment

Electricity: 380V 50Hz 3Phases

Techniques of plate making

4.2 Advanced Type of PS Plate Making Machine-CTP

Technical Data:

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Light Roller Rotate Speed

|

800rpm-900rpm Industry AVG. 600rpm, 50% higher Stability than usual with smaller size drum |

|||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Plate-in Method |

High Pressure Air, Touch-free Plate-in |

|||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Plate Absorb Method |

3 Chamber Sucking, Auto Sucking Area Adjustable subject to Plate Size, Free of Waving & Floating |

|||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Optic Lens Running Method |

maglev |

|||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Line-adding Method |

Frequency-adjustable, Format-adjustable, Mix-adding methods. Bi-digital halftone processing specially for metal printing. Dot output ratio control for color deviation. | |||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Color Management |

In-line with types of presses, Output preset data for printing | |||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Processor Data.

|

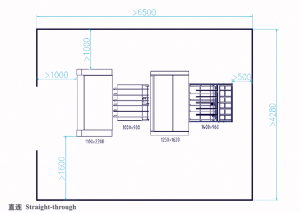

connection method: straight

PLC touch screen panel, problem auto indication precisely control 0.1℃ auto dynamic/static rehydration system auto glue-cleaning, and glue recycling, auto-lubrication 6. max processing size 1250mm 7. plate thickness:0.15mm~0.40mm |

|||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Stacker (1 SET) |

auto-stacking

suit to CTP system request |

|||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Conveyor (1SET) |

straight conveyor

suit to CTP system request |

|||||||||||||||||||||||||||||||||||||||||||||||||||||

|

CTP server (1SET) |

fits CTP system request, operation system pre-installed. | |||||||||||||||||||||||||||||||||||||||||||||||||||||

Main Parameter

|

Machine |

Attributor |

Specifications |

Remarks |

|

|

plate-making |

laser |

48-Channel Laser |

|

|

|

exposure |

830nm |

|

||

|

plate size |

Max.1230×1130mm |

|

||

|

plate thickness |

0.15-0.40mm |

|

||

|

pixel |

2400dpi |

|

||

|

net-adding |

frequency-adjusting |

20μm |

|

|

|

amplitude-adjusting |

300 Line |

|

||

|

max net cable connection |

300 Line |

|

||

| mesh-output |

1%-99% |

|

||

| repeat precision |

<0.01mm |

|

||

| plate uploading |

自动装版 auto load |

|

||

| speed |

Min.不少于12P/hr |

|

||

|

Others |

|

|

||

|

processor |

developer tank vol. |

60L |

|

|

| clean water tank vol.

|

20L |

|

||

|

developer temp.(adjustable) |

15-45℃ |

|

||

|

dryer temp (adjustable) |

this dryer only for liquid drying |

Baking is not mentioned hereby (baker will use 260-300℃ baking plate 6mins till gold color). | ||

| others |

water recycle |

|

||

|

conveyor |

plate workable size |

1250×1150×100mm |

|

|

|

Others |

|

|

||

|

stacker |

plate workable size |

1300×1150×(0.15—0.40)mm |

|

|

|

Other |

|

|

||

| installation power |

10.5kw |

|

|

|

Working & Installation Props.

| installation environment request | Temp.温度25℃±3℃

Humidity湿度20%~80% |

| main parameter | Max plate size: 1230*1130mm

Output pixel: 2400dpi |

| Facilities by end-user | Server supplied by customer: for file design flow purpose i7-7700k

VGA: above gtx.1050 RAM:16G SSD:128G Hard Disc: 2T Computer for the machine control server: GMA HD RAM 4G, H61 main board, IT hard disc |

Don’t hesitate to pop your inquires by mail: vente@eureka-machinery.com