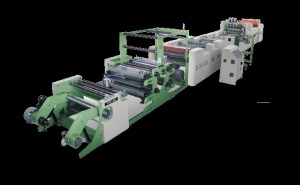

AFPS-1020LD Notebook/Exercise Book Flexo Printing Production Line

| Multipurpose use |

| Low production cost |

| Longer life |

| Sheet counting without changed counting gear |

| Deep pile delivery |

| Very good accessibility through L-shape especially during deep pile operation. |

| Easy to operate and low maintenance cost. |

| Staple pin exercise book |

| Drawings books without ruling. |

| Bunch of book block, suitable for spiral books, central sewn books etc… |

The exercise book production line is a highly sophisticated solution for the fabrication of staple pin exercise book, ruled and unruled pre-products, folded sheets or country specific finished products, It can be used for medium and large runs, from reel to the finished products. Basic machine consists of a single reel stand, flexo ruling, cross cutting, overlapping, collecting and counting, sheet feeding, wire stitching, folding, spine pressing, trimming of long sides, cutting into individual products, collecting of exercise book stacks and straight-on delivery.

|

Max. paper roll dia. |

1200mm |

|

Printing Width |

Max.1050mm, min.700mm |

|

Printing color |

2/2 on both sides |

|

Printing-Cutting Length |

Max.660mm, Min.350mm |

|

adjustment of printing length |

5mm |

|

Max. ruling width |

1040mm |

|

Cutting length |

Max.660mm, Min.260mm |

|

Max. machine Speed: |

Max.350m/min(Running speed based on paper GSM and quality ) |

|

Number of sheet layer |

6-50sheets, after folding 10-100 sheets |

|

Max. converting cycles |

60 times per min |

|

Inner page thickness |

55 gsm - 120 gsm |

|

Index page thickness |

100 gsm - 200 gsm |

|

Cover thickness |

150 gsm - 300 gsm |

|

Cover width |

Max.660mm, Min.260mm |

|

Max. cover pile height |

800mm |

|

Max. deliver pile height |

1500mm |

|

Stitching head quantity |

10 pcs |

|

Max. stitching thickness |

5mm ( after 10mm notebook thickness) |

|

Notebook binding width |

Max.300mm, Min.130mm |

|

Face trim |

Max.1050mm, min.700mm |

|

Side trim |

Max.300mm, Min.120mm |

|

Cutting thickness |

2mm-10mm |

|

Max. number of notebook block |

Max. 5 ups |

|

Total power: |

60kw 380V 3phase (depend on your country's voltage) |

|

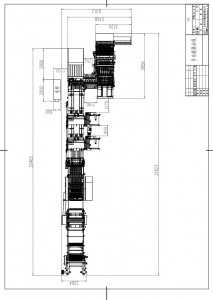

Machine dimension: |

L21.8m*W8.8m*H2.6m |

|

Machine weight |

Appr. 35.8 tons |

| Flexo Cylinder | 4 pcs |

| Side trimming Up Knife | 6 Pcs |

| Side trimming down Knife | 6 Pcs |

| Face Up Knife | 1 Pc |

| Rotary Up / down Knife | 1 Set |

| Feeding Belt | 20 m |

| impression cylinder | 1 PC |

| Double-side adhesive tape | 2 rolls |

| Stitching wire ( 15kgs/coils) | 8 coils |

| Tools box and manual | 1 set |

| 1 | Single station roll feed |

| - Clamping chuck: 3" | |

| - Reel pick-up via push button | |

| - Hydraulic tension control system | |

| - web edge control | |

| edge sensor can be moved on rails and clampled. | |

| 2 | Flexo ruling unit for 2/2 colors |

| - For integration of ruling units | |

| - Centralized lubrication system | |

| - Manual ruling cylinder lift-off upon machine stop | |

| - Pitch: 5mm | |

| - Coated impression cylinder | |

| - Steel anilox ink transmission cylinder | |

| 3 | Sheeter |

| 1 x cross cutter frame | |

| 1 x set of high speed steel knife | |

| 4 | Sheet overlapping |

| - one by one sheet overlapping | |

| 5 | Sheet Counting |

| - adopt Servo motor control | |

| - without counting gear | |

| 6 | Index pages inserting |

| 7 | Cover inserting |

| - adjustable suction head at back edge with blowing air between sheets. | |

| - automatic pallet lifting | |

| 8 | Pile delivery |

| Max. pile height: 1300mm | |

| 9 | Stitching unit |

| - installed 10 pcs of stitching heads Model: 43/6S Made in Germany | |

| 10 | Folding |

| -mechanical folder | |

| 11 | Spine Square |

| 12 | Face trim |

| 13 | Both sides and 3rd / 4th / 5th trim |

| 14 | Delivery table |

| 15 | Electrical controlling system |

| 1 | Stitch head | Hohner | Germany | |

| 2 | Breaking system | ChangLing | China | |

| 3 | rectifying device | JinPai | China | |

| 4 | mandrel type cam face cam splitter | TanZi | Taiwan | |

| 5 | Torque limiter | XianYangChaoYue | China | |

| 6 | Continuously variable transmission | Begema | Italy | |

| 7 | Reducer | LianHengJiXie | China | |

| 8 | Worm gear and worm reducer | TaiBangJiDian | Taiwan | |

| 9 | Lower friction cylinder | Kortis | China | |

| 10 | Combination magnetic clutch | YanXin | Taiwan | |

| 11 | Vacuum pump | Becker | Germany | |

| 12 | Circuit breaker | Schneider | France | |

| 13 | Electrothermal magnetic circuit breaker | Schneider | France | |

| 14 | Control button | Schneider | France | |

| 15 | Photoeletric switch | Banner | USA | |

| 16 | encoder | Omron | Japanse | |

| 17 | Ultrasonic sensor | Sick | Germany | |

| 18 | Exchanger | Siemens | Germany | |

| 19 | PLC | Siemens | Germany | |

| 20 | Bus adapter | Siemens | Germany | |

| 21 | Proximity switch | Autonics | Korea | |

| 22 | Normal open PNP Proximity switch | Festo | Germany | |

| 23 | Servo driver | Siemens | Germany | |

| 24 | Servo controller | Siemens | Germany | |

| 25 | V20 frequency inverter | Siemens | Germany | |

| 26 | Solenoid valve | Airtac | Taiwan | |

| 27 | Servo motor | Siemens | Germany | |

| 28 | Main motor | Phase | Italy | |

| 29 | Inching switch | TianDe | Taiwan | |

| 30 | Storage card | Siemens | Germany | |

| 31 | Model | Siemens | Germany | |

| 32 | Connecting terminal | YangMing | Taiwan | |

| 33 |

|

MingWei | Taiwan | |

| 34 | Touch screen | Delta | Taiwan | |

| 35 | ET 200 connecting terminal | Siemens | Germany | |

| 36 | Wire cable | Siemens | Germany | |

| 37 | Remoter control | DingYu | Taiwan | |

| 38 | Bearing | RCT | Germany | |

| 39 | Timing belt | Gates | USA | |

| 40 | adjust belt | Begema | Italy | |

| 41 | Air cylinder | Festo | Germany | |

| 42 | linear guider | ABBA | Taiwan |

Staple pin exercise book

Central sewn books

Bunch of book block,