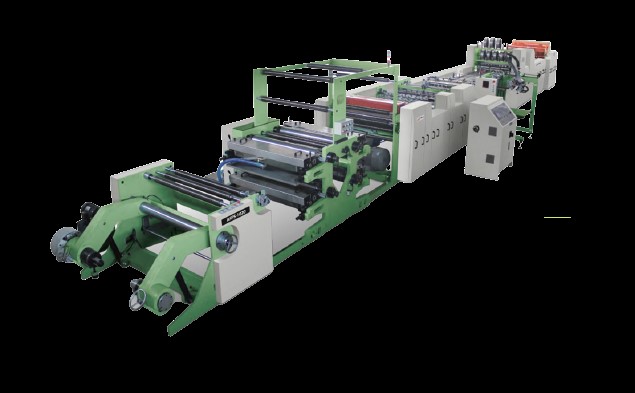

AFPS-1020A Fully Automatic Exercise Book Production Line

|

Max. paper roll dia. |

1200mm |

|

Printing Width |

Max.1020mm, min.580mm |

|

Printing-Cutting Length |

Max.480mm, Min.290mm |

|

in steps of gear |

5mm |

|

Max. size of notebook |

297*210mm |

|

Min. Size of notebook |

148 x 176 mm |

|

Printing color: |

2+2 (2 color on both side) |

|

machine Speed: |

Max.280m/min (Running speed based on the paper thickness) |

|

Inner sheet thickness: |

45g/㎡-120g/㎡ |

|

Number of sheet per groups: |

5-50 sheets, after folding 10-100 sheets = 20 pages to 200 pages |

|

Quit of stitching heads |

8 pcs |

|

Max. number of notebook block |

Max. 5 ups |

|

Cover thickness: |

150g-450g |

|

Max. cover pile height |

800mm |

|

Notebook thickness: |

10mm (unfolding book thickness:5mm) |

|

Article thickness (unfolded) |

5mm |

|

Max. output frequency |

45 times |

|

Total power: |

22kw 380V 3phase (depend on your country's voltage) |

|

Machine dimension: |

L21.8m*W2.5m*H2.4m |

| Flexo Cylinder |

4 Pcs |

Paper counting Synchronizing wheel |

3 pcs |

| Vertical Up Knife |

5 Pcs |

Horizontal Up Knife (W18A ) |

1 Pc |

| Rotary Up / down Knife |

1 SET |

Vertical Down Knife |

5 Pcs |

| Feeder Belt |

25 m |

Belt Lacing Machine |

1 Pc |

| Sheet counting gear |

4 pcs for 40 sheets, 38 sheets, 35 sheets and 25 sheets |

||

| 1, | Single Reel stand | 7, | Stitching (8 pcs stitching heads) | |

| 2, | Flexo ruling | 8, | Folding unit | |

| 3, | cross cutting | 9, | Spine Squared | |

| 4, | Sheet overlapping | 10, | Frontal trimming section | |

| 5, | Sheet Counting | 11, | Splitting and side trimming knives (5 pcs) | |

| 6, | Cover inserting | 12, | Delivery table | |