OEM/ODM China Auto Die Cutting Machine - Automatic Flatbed Die-cutting Machine MWZ1450QS for Cardboard Corrugated – Eureka

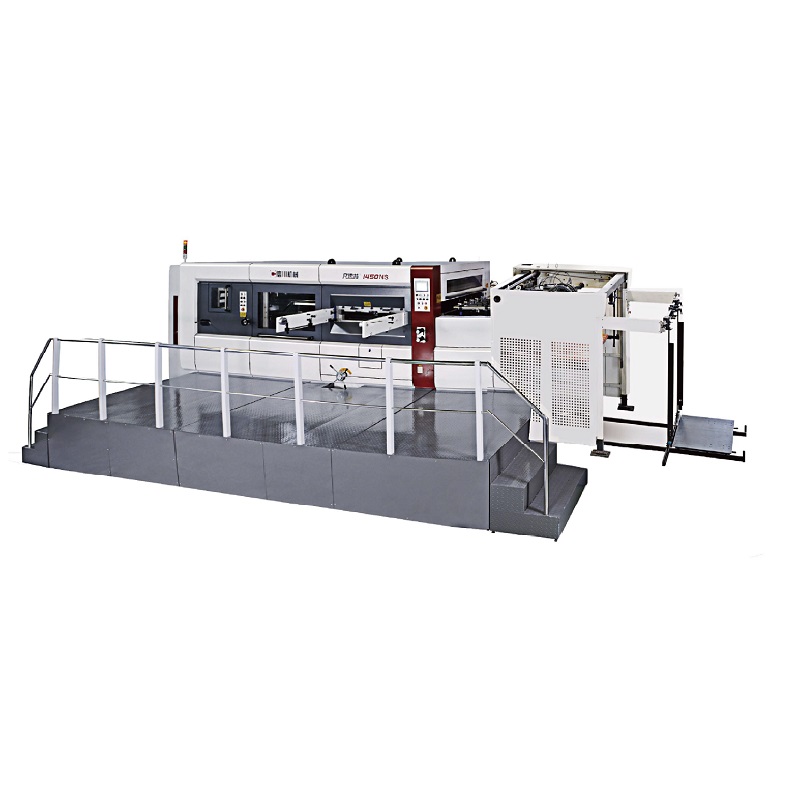

OEM/ODM China Auto Die Cutting Machine - Automatic Flatbed Die-cutting Machine MWZ1450QS for Cardboard Corrugated – Eureka Detail:

Built for quick set-up, safety, wide range stock and reducing damages to print sheets.

-This MWZ 1450S is able to handle solid board (min.200gsm) and corrugated board of single flute and doublewall of BC, BE up to 7mm.

-The feeder will offer stream feeding for solid board while singe sheet feeding for corrugated sheets.

-Feeding table with Pull and Push convertible Side Lay for accuracy.

-Gear driven and cast-iron build machine body for smooth and stable machine performance.

-Center line system equipped to be compatible with cutting forms used in flatbed die cutters of other brands. And to offer quick machine setup and job changes.

-Full stripping function (triple action stripping system and lead edge waste removal device) to savor labor cost and shorten delivery time to your customers.

-Non-stop High pile delivery system.

-Sheet blowing system and brush system at delivery section especially for solid board perfect collecting.

-Many safety devices and photo-sensors are equipped to protect operators from injury and to also protectmachine from incorrect operation.

-All the parts selected and assembled are built for stable performance and long run.

| Machine model | MWZ 1450QS |

| Maximum sheet size | 1480 x 1080mm |

| Minimum sheet size | 600 x 500mm |

| Maximum cutting size | 1450 x 1050mm |

| Maximum Cutting force | 300 Tons |

| Maximum mechanical speed | 5,200 sheets per hour |

| Production speed | 2,000~5,000 s/h subject to working environment, sheet quality and operation skills, etc. |

| Stock range | Corrugated sheet up to 7mm

Solid board 200-2000gsm |

| Height of cutting rule | 23.8mm |

| Pressure adjustment | ±1.5mm |

| Cutting precision | ±0.5mm |

| Min. front waste | 10mm |

| Maxi. Pile height at feeder (incl. pallet) | 1750mm |

| Maxi. Pile height at delivery (incl. pallet) | 1550mm |

| Chase size | 1480 x 1104mm |

| Power consumption (not included air pump) | 31.1kW // 380V, 3-PH, 50Hz |

| Dimension (L x W x H) | 10 x 5.2 x 2.6m |

| Machine weight | 27 Tons |

Sheet feeder

High speed and high precision top feeder with Four sucking cups and Six forwarding cups, sheets separates brush and fingers.

Stream feeding for solid board while singe sheet feeding for corrugated sheets.

Equipped with double sheet detection device

Feeding table

Servo system to control feeding speed.

Feeding table with Pull and Push convertible Side Lay foraccuracy.

Photoelectrical detector and rubber wheel for high speed feeding and precise registration.

Rubber wheel and brush wheel mechanism will be changed to below structure.

Die cutting section

Automatic and independent self-lubrication system built to save maintenance job.

Center line system for quick cutting die set up and change over.

Safety door and die chase safety locking system to ensure safe operation.

Automatic and independent Self-lubrication system for main drive chain.

Equipped with worm wheel, crankshaft working with toggle-type die cutting lower platform.

Torqure limitor protection

Siemens touch screen

Stripping section

Center line system for quick stripping die set up and job change over and applicable to stripping dies of other brands die cutting machines.

Equipped with Safety window for safe operation

Photo sensors for paper waste detecting and keep machine running in neat condition.

Triple action stripping system

Front waste separator device removes and transfers waste edge to machine drive side by conveyor belt.

Delivery Section

High pile delivery system

Safety window for safety, monitoring delivery action and adjusting the side joggers

Front, back and side joggers to ensure neat stacking.

Sheet air blowing system and sheet brush system for perfect sheets collecting.

Easy-Adjustable Side and rear joggers for quick set up.

Electrical Control Section

Siemens PLC technology.

YASKAWA frequency inverter

All electrical components meet CE standard.

Standard Accessories

1) Two sets of gripper bars

2) One set of work platform

3) One pcof cutting steel plate (material: 65Mn, thickness: 5mm)

4) One set of tools for machine installation and operation

5) One set of consumable parts

6) Two waste collecting boxes

7) One set of pre-loader

Company Introduction

A Chinese leading manufacturer and supplier of flatbed die-cutters and post-press converting line to corrugated board packages manufacturers.

47000 m2 manufacturing space

3,500 installations completed worldwide

260 employees (November, 2020)

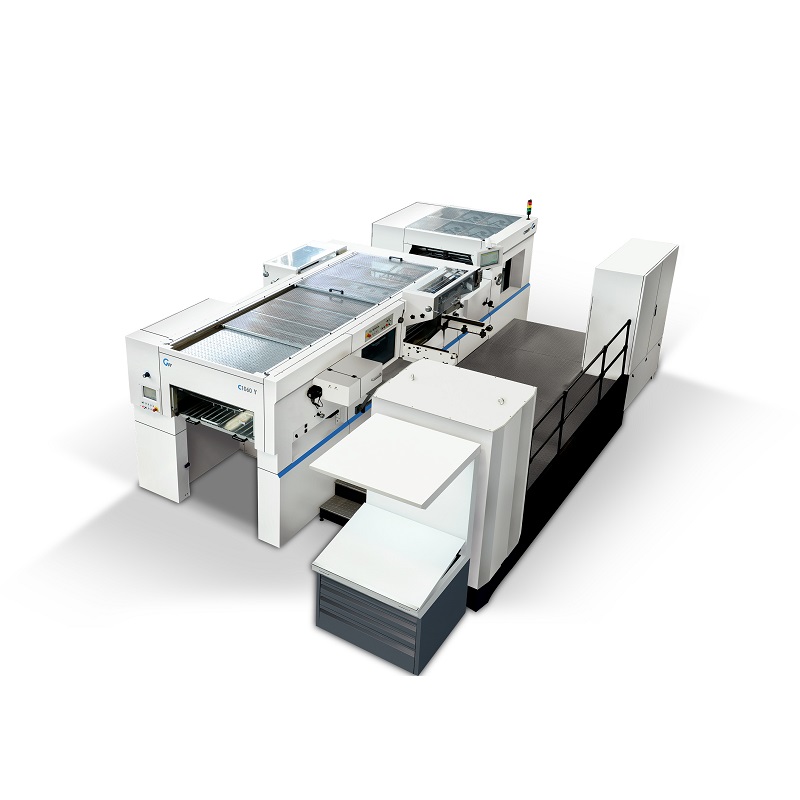

Product detail pictures:

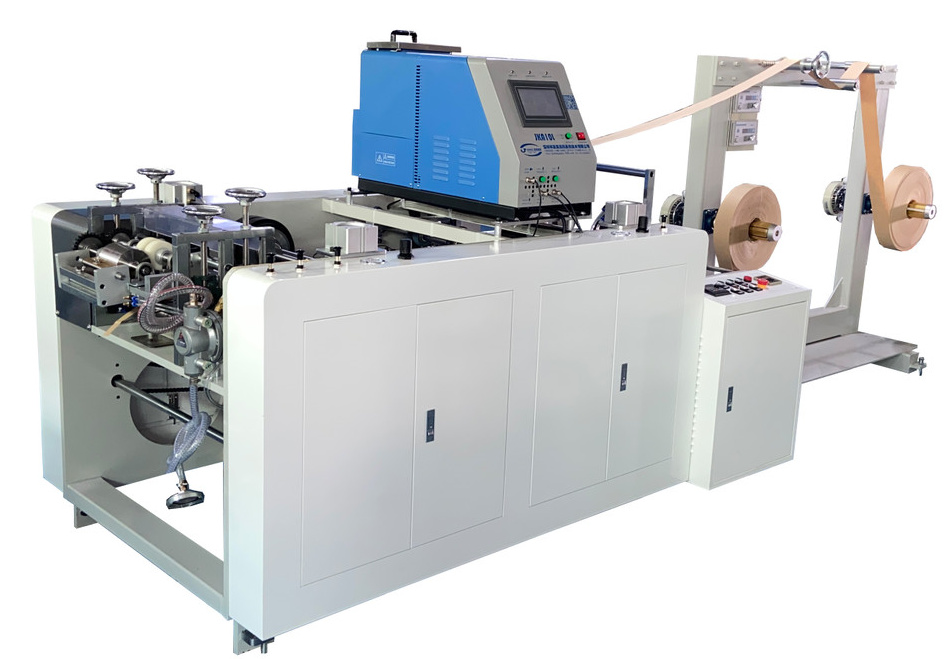

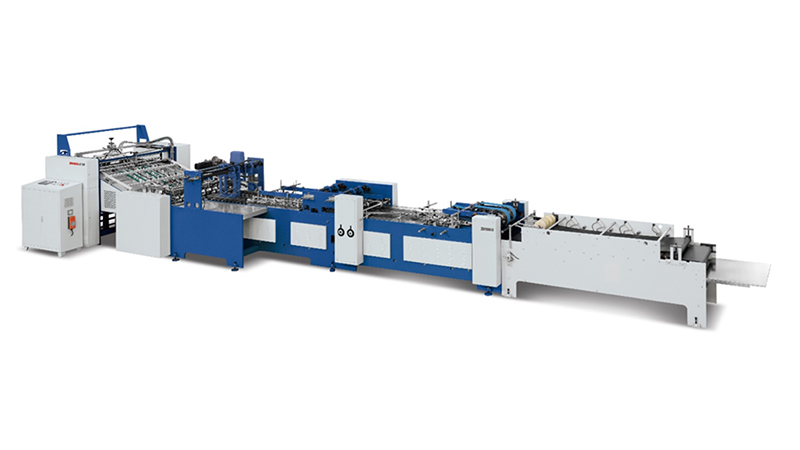

Related Product Guide:

"Quality first, Honesty as base, Sincere service and mutual profit" is our idea, in order to develop continuously and pursue the excellence for OEM/ODM China Auto Die Cutting Machine - Automatic Flatbed Die-cutting Machine MWZ1450QS for Cardboard Corrugated – Eureka , The product will supply to all over the world, such as: Peru, Greenland, Singapore, We have been fully aware of our customer's needs. We deliver high quality products, competitive prices and the first class service. We would like to establish good business relationships as well as friendship with you in the near future.

Cooperate with you every time is very successful, very happy. Hope that we can have more cooperation!