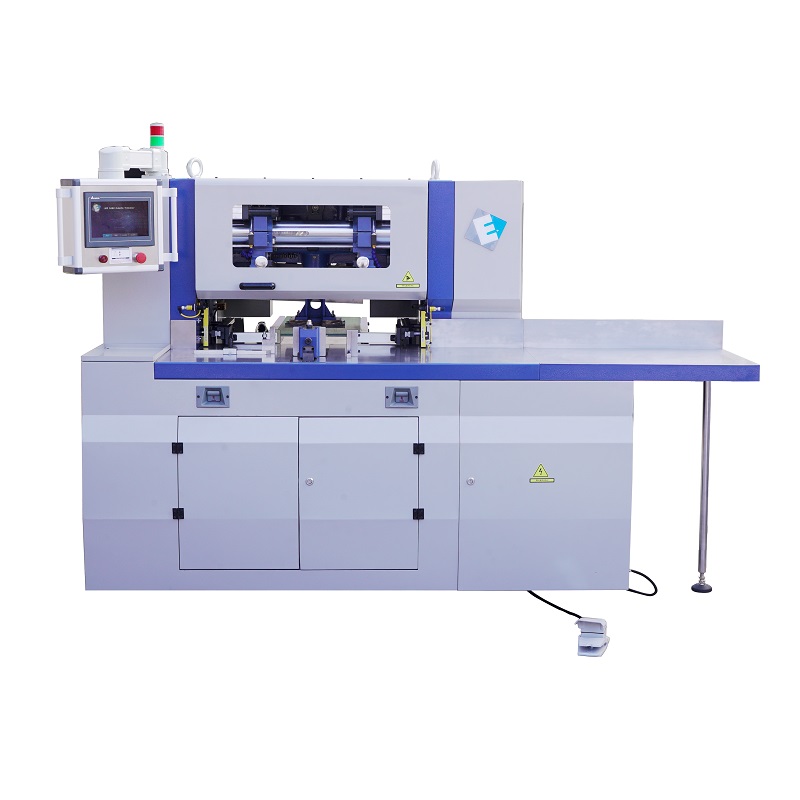

Good Wholesale Vendors Precision Paper Cutter Machine - THE GW- P HIGH SPEED PAPER CUTTER – Eureka

Good Wholesale Vendors Precision Paper Cutter Machine - THE GW- P HIGH SPEED PAPER CUTTER – Eureka Detail:

Sizes Available

GW-P guillotine cutters come in five cutting sizes:

31″/80CM

36″/92CM

45″/115CM

54″/137CM

69″/176CM

Looking through the GW-P. Here’s a glance at just some of what GW-S high speed cutters offer

Highlight Features

Our GW-P computer control unit with 15” color touch screen for automating backgauge movement is the most user-friendly system in the industry,50000+ programs for job saving and has keyboard.

Cutting power is provided by a hydraulic clutch and time-tested worm gear design

Cushion contact clamping eliminates pile disturbance.

High-speed steel knives offer extended durability.

High Performance

Air table with built-in blower allows for easy material movement.

One-hand control of the back gauge for fast and precise settings, driven by YASKAWA Servo system.

Easily adjustable, electronic, programmable hydraulic clamping system.

The knife lifting unit allows for fast, simple, safe knife changes

Strong, Durable Using

One-piece, chrome-plated, slotless cast iron table is sturdy and easy to maintain

Oversize chromed, cast iron side tables with air are standard

The knife bar is guided by dual gibs, engineered for rigidity and cutting accuracy

Ball screw and dual liner guide guarantee precise back gauge positioning

Our soft clamp foot treadle feature assures safe, 30KG safety pressure, easy use of the clamp

Optional Pilz safety module, AB light barrier and all CE standard electronic components, can be build in CE standard

Numerous other features such as knife bar overloads, infrared light barriers

| Model |

GW80P |

GW92P |

GW115P |

GW137P |

GW176P |

| Size (cm) |

80 |

92 |

115 |

137 |

176 |

| 15 inch screen |

○ |

○ |

○ |

○ |

○ |

| Touch screen |

△ |

△ |

△ |

△ |

△ |

| Memory |

|

|

|

|

|

| Back gauge speed 16m |

○ |

○ |

○ |

○ |

○ |

| Double guide ball screw |

○ |

○ |

○ |

○ |

○ |

| Chromed air table |

○ |

○ |

○ |

○ |

○ |

| Large vice working table 1000 x 750mm |

× |

× |

△ |

△ |

△ |

| Electric-magnet clutch |

× |

○ |

× |

× |

× |

| hydraulic clutch, Italy gear pump |

○ |

△ |

○ |

○ |

○ |

| German Wessel hydraulic system |

△ |

△ |

△ |

△ |

△ |

| On-line & USB program function available |

× |

× |

× |

× |

× |

| Optimized cutting |

× |

× |

× |

× |

× |

| Self diagnose system |

○ |

○ |

○ |

○ |

○ |

| Clamp pressure programmable |

△ |

△ |

△ |

△ |

△ |

| Rear table cover |

△ |

△ |

△ |

△ |

○ * |

| 30kg safety pedal pressure |

△ |

△ |

△ |

△ |

△ |

| TUV CE |

△ |

△ |

△ |

△ |

△ |

| PILZ module, redundant control, Leuze light barrier |

|

|

|

|

|

| ○Standard ×Not configured △ Option *GW 176 Safety pressure is 50KG |

|

|

|

||

1.Au19 inch industrial grade color touch screen

2.No limit clamp pressure adjustment system animation demonstration

3.Secure and convenient knife change

4.Knife stick ejecting device

5.Centralization lubrication

6.Electrical cam option

7.Intensi_ed air cushion working table

8.PLE grade safety standard, self-diagnosis PILZ safety module

9.Worm gear drive system, imported electronic cam, knife position detection system

10.Protective Infrared Light Curtain with PLE Safety Standard

11.Seamless working table, ball screw, double guide

12.Optional German imported hydraulic system

13.Italy hydraulic pump

14.Casting part use resin sand, HT250/ HT300

15.Imported high accurate positioning servo system

16.Auto. Lubricating Device

| Model | 80 | 92 | 115 | 137 | 176 |

| Cutting width (mm) | 800mm | 920mm | 1150mm | 1370mm | 1760mm |

| Cutting length (mm) | 800mm | 920mm | 1150mm | 1450mm | 2000mm |

| Cutting height (without false clamp plate) | 130mm | 130mm | 165mm | 165mm | 165mm |

| Main motor power | 3kw | 3kw | 4kw | 4kw | 7.5kw |

| Net weight | 2200kg | 2800kg | 3800kg | 4500kg | 7500kg |

| Machine width | 2105mm | 2328mm | 2680mm | 2900mm | 3760mm |

| Machine length | 1995mm | 2070mm | 2500mm | 2823mm | 3480mm |

| Machine height | 1622mm | 1622mm | 1680mm | 1680mm | 1730mm |

| Clamp pressure min. | 1.5KN | 1.5KN | 1.5KN | 1.5KN | 3KN |

| Clamp pressure max. | 30KN | 30KN | 45KN | 45KN | 70KN |

| Blade specification | 12.7mm | 12.7mm | 13.75mm | 13.75mm | 13.75mm |

| Grinding reserve | 30mm | 30mm | 60mm | 60mm | 60mm |

| Smallest cut without false clamp | 18mm | 25mm | 25mm | 25mm | 35mm |

| Smallest cut with false clamp | 52mm | 85mm | 90mm | 90mm | 120mm |

| Cutting speed | 45 time/min | 45 time/min | 45 time/min | 45 time/min | 45 time/min |

| Packing size (LxWxH) | 2250x1400x1850mm | 2250x1400x1850mm | 2650x1450x2000mm | 2950x1550x2000mm | 3700x1600x2300mm |

| Power supply | 3Ph 400V 50Hz | 3Ph 400V 50Hz | 3Ph 400V 50Hz | 3Ph 400V 50Hz | 3Ph 400V 50Hz |

Product detail pictures:

Related Product Guide:

Our company insists all along the quality policy of "product good quality is base of enterprise survival; buyer fulfillment will be the staring point and ending of an company; persistent improvement is eternal pursuit of staff" and also the consistent purpose of "reputation very first, shopper first" for Good Wholesale Vendors Precision Paper Cutter Machine - THE GW- P HIGH SPEED PAPER CUTTER – Eureka , The product will supply to all over the world, such as: Cambodia, Paris, Mombasa, Our company is working by the operation principle of "integrity-based, cooperation created, people oriented, win-win cooperation". We hope we can have a friendly relationship with businessman from all over the world.

We feel easy to cooperate with this company, the supplier is very responsible, thanks.There will be more in-depth cooperation.