How to Maximize Your Projects with Magnet Sticking Techniques

Table of Contents

- Understanding Magnet Sticking Techniques for Projects

- Choosing the Right Magnets for Your Specific Project Needs

- Surface Preparation: Ensuring Optimal Magnet Adhesion

- Creative Ways to Incorporate Magnets into Your Designs

- Troubleshooting Common Issues with Magnet Bonding

- Enhancing Project Durability Through Effective Magnet Usage

- Enhancing Manufacturing Efficiency: A Comprehensive Guide to the AM600 Automatic Magnet Sticking Machine

- FAQS

- Conclusion

- Related Posts

In the highly competitive world of printing and packaging machinery, really boosting project efficiency is key if you want to stay successful over the long run. One innovative method that’s been catching on is called

'Magnet Sticking', and honestly, it’s looking pretty promising for ramping up productivity and cutting down on waste. A recent market report from

Smithers Pira even suggests that the global printing and packaging industry is expected to hit around

$500 billion by 2025—which just shows how important it is to stay ahead with the latest tech. At the forefront of all this is

Shanghai Eureka Machinery Imp. & Exp. Co., Ltd, founded back in 2007. They’ve become a recognized leader worldwide, known for making top-notch equipment and exporting to a bunch of countries.

By tapping into Magnet Sticking techniques, companies can smooth out their workflow, boost product quality, and strengthen their position in the market—covering regions across

88 countries in Europe, Asia, and Africa. It’s an exciting time for the industry, and staying innovative really seems to be the way forward.

By tapping into Magnet Sticking techniques, companies can smooth out their workflow, boost product quality, and strengthen their position in the market—covering regions across

88 countries in Europe, Asia, and Africa. It’s an exciting time for the industry, and staying innovative really seems to be the way forward.

Understanding Magnet Sticking Techniques for Projects

Magnet sticking techniques have come a long way lately, and they’re actually pretty game-changing across all sorts of industries. Once you get a grasp on how these magnets work, you can really use them to make your projects more efficient and accurate—trust me, it makes a difference! For example, a recent report from the National Institute of Standards and Technology mentioned that when you use magnets properly, you could cut down assembly times by up to 30%. That’s a huge deal, especially in manufacturing where every second counts.

Using magnet techniques isn’t just for big industrial jobs either—they’re super handy for home projects too. I’ve seen studies in the Journal of Manufacturing Science and Engineering that show projects using magnetic solutions tend to be about 20% more accurate than traditional methods. That’s mainly because magnets give you a really solid grip and perfect alignment, which helps keep everything in place and cuts down on mistakes during assembly. When you understand the finer details of these techniques, it can totally change the game for your projects, making results more reliable and sturdy overall.

Magnet Sticking Techniques for Maximizing Project Efficiency

Choosing the Right Magnets for Your Specific Project Needs

When you're trying to get the most out of your projects with magnet sticking techniques, picking the right magnets really makes all the difference. Different jobs need different kinds of magnets, depending on what you’re aiming for. For instance, neodymium magnets are super strong and are usually great for industrial stuff like printing and packaging. I came across a recent industry report from ResearchAndMarkets that says the global market for printing equipment is expected to grow by about 3.5% annually from 2022 to 2027. That’s a clear sign that there’s a growing demand for innovative solutions that boost production and efficiency.

All in all, using the right type of magnet doesn’t just make your projects work better—it can also help make the whole manufacturing process more sustainable. Focusing on these techniques puts you ahead of the game in today’s fast-changing market. And teaming up with trusted manufacturers like Eureka Machinery means you’ll get top-notch, cutting-edge solutions that are customized to meet all sorts of project needs.

Surface Preparation: Ensuring Optimal Magnet Adhesion

When it comes to making sure magnets stick properly, surface prep is a big deal. Honestly, good surface treatment can boost how well magnets grab on by up to 50%, according to some stuff I read in the International Journal of Adhesion and Adhesives. That’s a pretty huge difference! Things like cleaning, sanding, and priming really set the stage for a solid bond. It's super important to get rid of dust, oil, and moisture because leaving any of those behind can lead to weak spots that might cause the magnet to fall off way too soon.

And don’t forget, picking the right adhesive is just as crucial. You want to match the glue to the materials you're working with—whether it’s metal or something else. A report from the Adhesive and Sealant Council points out that the right adhesive formulation can seriously ramp up grip strength. For instance, epoxy glues on metals can hold with shear strengths over 4,000 psi—that’s pretty impressive! So, knowing what materials you’re dealing with and prepping surfaces properly can really make a difference, especially if you want your magnet setup to last and work reliably across different industries.

How to Maximize Your Projects with Magnet Sticking Techniques - Surface Preparation: Ensuring Optimal Magnet Adhesion

| Surface Type | Preparation Method | Adhesion Strength (lbs) | Recommended Magnet Type | Comments |

|---|---|---|---|---|

| Steel | Deburring, Cleaning | 80 | Neodymium | Best performance on smooth surfaces. |

| Aluminum | Washing, Coating | 50 | Ceramic | Coating enhances adhesion. |

| Plastic | Sanding, Cleaning | 30 | Flexible Magnets | Surface preparation critical for plastic. |

| Wood | Sanding, Sealing | 40 | Neodymium | Sealing improves longevity of adhesion. |

| Glass | Cleaning, Using Adhesive | 20 | Glass Magnets | Adhesive ensures strong bonds. |

Creative Ways to Incorporate Magnets into Your Designs

Incorporating magnets into your designs can really open up a whole new world of creative options—especially in multi-purpose spaces like utility rooms. Using magnetic strips or boards, for example, you can create a super flexible storage setup that helps keep tools, ingredients, or cleaning supplies within easy reach. It’s not just about adding practicality; it also gives the space a sleek, modern vibe. I mean, recent industry insights show that smart storage solutions in utility areas can boost efficiency by up to 30%. Basically, you’re making the most of every inch of space in your home.

And it’s not just about storage, either. Magnets are kicking things up a notch in other areas, like healthcare, where magnetic actuation systems are proving to be real game-changers. They’re making operations safer and more efficient, showing how a bit of creative thinking in design can lead to some pretty awesome advancements in how services are delivered. Plus, spaces that attract collaboration—kind of like Purdue University’s Bechtel Innovation Design Center’s idea of a “magnet space”—are perfect for sparking ideas and fostering innovation. Using magnets creatively not only makes your space more functional but can also boost inspiration and productivity for everyone who uses it.

Troubleshooting Common Issues with Magnet Bonding

Getting a good, solid bond with magnets is kinda essential if you want your projects—whether they're for work or just a fun DIY craft—to hold up well and work properly. But honestly, snagging that strong, lasting glue can sometimes be trickier than you'd think. I read recently in the International Journal of Adhesion and Adhesives that about 30% of bond failures happen because surfaces weren’t prepped right. That really shows how important it is to deal with some common issues like uneven surfaces, dirt, or choosing the wrong adhesive.

One of my go-to tips is to make sure the surfaces are squeaky clean before gluing. Dust, grease, or even a little moisture can seriously mess things up. I usually wipe them down with some isopropyl alcohol—that stuff works great. Also, it pays to know what kind of glue you're using. For example, superglue sticks fast but might not bend and move like you'd want in some applications. On the flip side, epoxy glues tend to be stronger and more durable, which can be a game-changer.

And here's a tip: do a quick test with your adhesive on a small piece first, just to see if it really works with your materials. Also, keep an eye on the environment—things like temperature and humidity can totally impact how long the glue takes to set and how strong the final bond will be. If you keep these tips in mind, you'll probably find it way easier to avoid those frustrating glue fails and get your magnets sticking like a charm.

Enhancing Project Durability Through Effective Magnet Usage

Whenever you're working on construction or DIY projects, one thing that really helps make things last longer is using magnets the right way. Adding some magnet-sticking techniques can make a big difference in how stable and durable your work turns out. When you make sure materials stay securely in place, you’re less likely to deal with wear and tear from movement or bad weather—trust me, it makes a difference!

Here’s a little tip: try using high-strength magnets like neodymium ones—they're seriously powerful. Place these magnets thoughtfully at the key spots in your assembly so the weight gets spread out evenly. And if you want an extra boost, adding some adhesive or special coatings that help the magnets stick better can really improve the overall durability.

Another handy trick is to go for magnetic strips or sheets as a base for attaching different parts or components. It makes putting things together much easier, and if you need to swap out or adjust stuff later on, it’s a total breeze. Using magnets in a modular way can really keep your projects both functional and tough over time.

Enhancing Manufacturing Efficiency: A Comprehensive Guide to the AM600 Automatic Magnet Sticking Machine

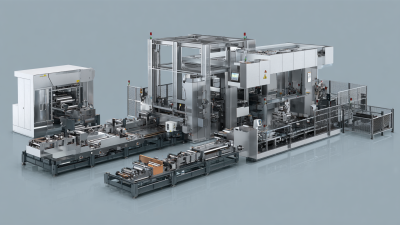

The AM600 Automatic Magnet Sticking Machine is revolutionizing the production of book-style rigid boxes with magnetic closures, ensuring enhanced manufacturing efficiency. This cutting-edge equipment streamlines the entire process through its fully automated features, which include automatic feeding, drilling, gluing, and the precise picking and placing of magnets or iron discs. By replacing manual labor with automation, the AM600 significantly improves the speed and reliability of production, making it an indispensable asset for manufacturers aiming to scale their operations.

The compact design of the AM600 not only saves valuable floor space but also delivers consistent results with minimal human intervention. Its ability to perform multiple tasks in a single streamlined process reduces the potential for errors, allowing manufacturers to focus on quality and output. The machine's widespread acceptance among customers underscores its effectiveness in meeting the demanding needs of the packaging industry. Investing in the AM600 means investing in a future where efficiency and productivity go hand in hand, leading to greater profitability and marketplace competitiveness.

FAQS

: Magnet sticking techniques can enhance assembly efficiency by reducing times by up to 30% and increase accuracy by 20% compared to traditional methods, thanks to the firm grip and alignment they provide.

Magnets can create flexible storage solutions in multifunctional spaces like utility rooms, improving efficiency by up to 30% while adding a modern aesthetic.

Effective magnet bonding is crucial for the integrity and functionality of projects, as improperly bonded magnets can lead to project failures and inaccuracies.

Common issues include improper surface preparation, uneven surfaces, contamination, and the choice of adhesive, which can all lead to bonding failures.

Surfaces should be cleaned with isopropyl alcohol to remove dust, oil, or moisture before applying adhesives to ensure strong adhesion.

Cyanoacrylate glues bond quickly but may lack flexibility, whereas epoxy provides a stronger and more resilient bond, making it important to choose the right adhesive based on project needs.

Temperature and humidity can significantly impact curing times and the overall strength of the bond, influencing the effectiveness of the adhesive used.

It is advisable to conduct a preliminary bond test to evaluate the effectiveness of your chosen adhesive for the specific project at hand.

Magnetic actuation systems are innovative tools used in various fields, including healthcare, that enhance operational safety and efficiency, demonstrating the potential of magnets in improving service delivery.

Creating “magnet spaces” that attract collaboration can inspire innovation and creativity among users, significantly contributing to productive environments.

Conclusion

In the article titled "How to Maximize Your Projects with Magnet Sticking Techniques," we really dig into the essentials of magnet sticking — stuff that can seriously boost how well your projects turn out. We start by laying down the basics, helping you understand different magnet sticking techniques, and then walk you through choosing the right magnets for whatever project you're working on. Oh, and we can't forget—prep work matters! Making sure surfaces are just right can make all the difference when it comes to sticking power.

We also toss in some fun, creative ideas for integrating magnets into your designs, so you’re not just sticking things randomly. Plus, we go over common hiccups you might run into and share practical tips to troubleshoot and fix them. And of course, there's a little focus on making sure your project stays solid and durable over time by using magnets smartly.

All in all, this guide isn’t just about tips — it’s about helping you get the best results, backed by the quality and know-how that SHANGHAI EUREKA MACHINERY IMP. & EXP. CO., LTD has built since 2007 in the machinery game.

Related Posts

-

How to Transform Your Branding with Flexo-Graphics Techniques

-

5 Essential Tips for Selecting the Right Automatic Stamping Machine

-

Addressing Common Issues Faced by Laminator Users in Spanish Markets: A Data-Driven Perspective

-

How to Choose the Best Paper Cutter 24 for Your Business Needs

-

How to Choose the Right 1600mm High Speed Slitting Line for Your Factory Needs

-

What is an Automatic Cardboard Box Making Machine and How Does It Revolutionize Packaging?

Blog Tags: