Addressing Common Issues Faced by Laminator Users in Spanish Markets: A Data-Driven Perspective

Table of Contents

- Understanding the Unique Laminator Needs in Spanish Markets

- Key Challenges Faced by Laminator Users in Spain

- Data Trends: Laminator Usage Patterns in Spanish Industries

- Solutions to Enhance Laminator Performance for Local Users

- Best Practices for Laminator Maintenance and Troubleshooting

- Customer Support: Building Trust with Spanish Laminator Users

- Optimizing Flute Laminator Efficiency: Insights from Industry Reports on Automatic Flip Flop Stackers EUSH 1450/1650

- FAQS

- Conclusion

- Related Posts

In today’s fast-changing world of printing and packaging, it’s pretty clear that folks are really looking for more reliable and efficient laminating machines. Especially here in Spain, the demand has shot up quite a bit. If you’ve kept an eye on recent industry chatter, you’ll notice that the market for laminating equipment is expected to grow a lot in the coming years — mainly because businesses want packaging that's both tough and looks good.

Shanghai Eureka Machinery, which has been around since 2007, is actually a pretty big player in this space. They’re known for making and exporting top-notch printing and packaging gear to around 88 countries, including Spain. This blog’s gonna dive into some of the common issues laminator users in Spain face—and use some solid data to suggest practical tips to get things running smoother. Our goal is to really understand the specific challenges around laminators in Spain, help users out, and give the whole industry a little boost along the way.

Shanghai Eureka Machinery, which has been around since 2007, is actually a pretty big player in this space. They’re known for making and exporting top-notch printing and packaging gear to around 88 countries, including Spain. This blog’s gonna dive into some of the common issues laminator users in Spain face—and use some solid data to suggest practical tips to get things running smoother. Our goal is to really understand the specific challenges around laminators in Spain, help users out, and give the whole industry a little boost along the way.

Understanding the Unique Laminator Needs in Spanish Markets

When it comes to the Spanish market, laminator users often face some pretty unique challenges that really call for tailored solutions. Understanding what local folks prefer and what their operational needs are is super important if you want to make your laminating process smoother and more effective. For example, you know how Spain’s climate varies—humid in some regions, dry in others? Well, those fluctuations in humidity and temperature can actually mess with how well your laminator performs. Companies like SHANGHAI EUREKA MACHINERY IMP. & EXP. CO., LTD, who have a solid presence in 88 countries, totally get these kinds of needs—and they tweak their machines accordingly to keep things running smoothly.

A few tips if you're using a laminator in Spain: first off, choose the right laminating film that matches your local environment to avoid annoying issues like bubbling or peeling. Don’t forget, regular maintenance is key—schedule some routine checks to keep your machine in top shape and extend its lifespan. And hey, investing in proper training for your team can really make a difference—knowing the best practices for running your laminator not only speeds things up but also boosts the quality of your output, helping you tackle those common hiccups you might face right here in this market.

Common Issues Faced by Laminator Users in Spanish Markets

Key Challenges Faced by Laminator Users in Spain

The lamination industry in Spain is currently facing quite a few hurdles, and these are pretty much tied to bigger economic trends and how consumers are behaving these days. One of the main issues? Rising material costs, which have been pushed even further by swings in the energy market. I read that over 70% of people using laminators say that the jump in raw material prices is hitting their operating costs hard. As Spain goes through these economic adjustments — with price hikes expected in multiple sectors — it’s super important for lamination businesses to get creative and find ways to keep costs under control.

On top of that, there’s also some frustration around outdated lamination tech. Many folks feel it just doesn’t cut it anymore, especially when it comes to high-volume jobs. Recent reports show that nearly 65% of users have faced delays because their equipment isn’t up to date. As competition gets tougher in the Spanish market, it’s clear that lamination companies need to start investing in newer, smarter automation solutions — not only to boost productivity but also to keep customers happy.

Industry experts are even saying that businesses switching to more advanced tech could see efficiency gains of up to 20%, which could make a real difference in this fast-changing environment.

Data Trends: Laminator Usage Patterns in Spanish Industries

So, when you look at how laminators are used across Spanish industries these days, the recent data really highlights some interesting trends. It’s clear that tech advancements, especially with digitalization, AI, and IoT, have completely changed the game. Companies are now adopting smarter laminating machines that not only boost efficiency but also help better manage resources—pretty important given everything going on with climate change, especially when it comes to groundwater issues in the Iberian Peninsula.

And if you dig into industry reports, you’ll see that how well a laminator performs often depends on how much products need to be made — demand drives the usage. But it’s not just about production; economic ups and downs, and environmental factors are influencing things too. More and more, businesses are shifting toward eco-friendly solutions—they’re investing in laminators that do the job well but also save energy. In fact, recent findings show that companies switching to greener laminating options are actually reducing operational costs. It’s all part of a bigger move towards more responsible practices for the environment. As the Spanish market keeps evolving, using data like this is super helpful for tackling challenges and spotting new opportunities in the laminating world.

Solutions to Enhance Laminator Performance for Local Users

In the competitive Spanish market, folks who use laminators often run into all sorts of challenges that can slow them down or affect quality. Spotting these issues early on is actually pretty important if you want to work smarter and get better results. Common headaches include frequent jams, inconsistent glue application, and struggling to get that perfectly even finish. But here’s the good news: by digging into data and really understanding these pain points, users can find smarter ways to fix them and boost their laminator’s performance.

At Eureka Machinery, we’re all about helping our clients in the printing and packaging business tackle their unique challenges. With experience working across 88 countries, we’ve picked up a ton of insights that help us meet local market needs. We’re strong believers in embracing new tech and sticking to regular maintenance to prevent those pesky issues from cropping up. Plus, by providing customized training for operators and tapping into advanced performance analytics, companies can totally level up their laminating game—making the process smoother, faster, and producing top-notch quality every time.

Best Practices for Laminator Maintenance and Troubleshooting

Taking good care of your laminator is super important if you want it to run smoothly and last a long time. I read a recent report from the Association of Suppliers of Paper, Film & Foil (ASPF), and it turns out that about 35% of laminator failures happen because of poor maintenance. So, regularly cleaning those rollers and tweaking the temperature based on what kind of laminate you're using can really make a difference. For example, getting the right pressure settings not only helps your machine last longer but also keeps the film sticking properly. Interestingly, using the wrong settings can actually reduce how well the film adheres—by up to 20%, they say!

Also, troubleshooting often comes down to knowing the common problems that pop up in lamination. A survey from the European Laminating Industry Association (ELIA) found that almost 40% of folks see bubbles or wrinkles during lamination. More often than not, that’s because of incorrect film thickness or wrong temperature settings. Things like preheating your film and using good-quality materials really help prevent these issues. Plus, keeping an eye on your machine’s performance through regular data checks can make troubleshooting a lot easier, helping you get the best out of your laminator. All in all, paying attention to these little details can seriously boost productivity, especially if you're working within the Spanish market.

Customer Support: Building Trust with Spanish Laminator Users

Building trust with folks who use laminators in Spain is super important if we wanna keep those relationships going strong and make sure everyone’s happy with their experience. A recent report from Smithers Pira showed that around 60% of laminator users in Spain are kinda worried about whether customer support is reliable. That really points to how crucial it is for companies to have support teams that actually respond quickly and know their stuff—so users don’t feel left hanging. When brands step up with top-notch customer service, not only do users get a better experience, but they also tend to stick around longer and become more loyal. Over time, that can really help a company grab more market share in Spain’s pretty competitive laminating scene.

On top of that, the same report mentions that over 75% of Spanish laminator users really appreciate support that’s personalized and meets their specific needs. This clearly shows that businesses should put some effort into training their support staff—not just on the tech stuff but also on understanding the local challenges and what users really want. Using tools like data analytics and listening to customer feedback can help companies spot common problems before they even happen, so they can offer solutions early on and build a reputation as real partners. With laminating demand only growing, tackling these customer support issues is gonna be a key piece of the puzzle for gaining loyalty from users all across Spain.

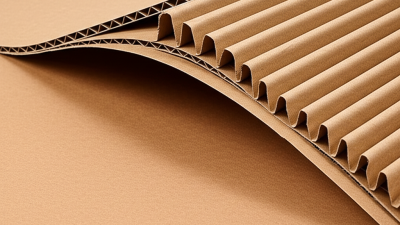

Optimizing Flute Laminator Efficiency: Insights from Industry Reports on Automatic Flip Flop Stackers EUSH 1450/1650

The efficiency of any flute laminator is pivotal in meeting production demands, and the integration of automatic flip flop stackers, particularly the EUSH 1450/1650 models, plays a significant role in optimizing this process. Recent industry reports indicate that automation in stack management can elevate production speeds substantially, with systems like the EUSH Flip Flop delivering rates between 5000 to 10000 pieces per hour. This remarkable efficiency not only increases throughput but also reduces labor costs and errors associated with manual stacking.

The EUSH Flip Flop is designed to seamlessly work with the EUFM Series high-speed flute laminators as well as other brands, showcasing its versatility in various production environments. With a maximum paper size handling capacity of 1450*1450mm or 1650*1650mm and a minimum size of 450*550mm, the EUSH Flip Flop caters to a wide range of operational needs. Industry analysts report that by implementing such advanced stacking solutions, companies can achieve a higher return on investment (ROI) through enhanced throughput and reduced operational downtime.

Incorporating automated technologies like the EUSH Flip Flop not only maximizes efficiency but also maintains the quality integrity of laminated products, an essential factor within the competitive market landscape. As businesses continue to push for higher performance, the adoption of such technologies will undoubtedly serve as a crucial differentiator in manufacturing capabilities.

FAQS

: One of the main challenges is the rising cost of materials, heavily influenced by fluctuations in the energy market.

Over 70% of laminator users report that rising raw material prices significantly impact their operational costs.

Many users are dissatisfied with outdated lamination technology, which struggles to meet the demands of high-volume production and has resulted in delays for nearly 65% of users.

Businesses that adopt advanced lamination technologies could see up to a 20% increase in efficiency.

Users often experience frequent jams, inconsistent adhesive application, and difficulty achieving uniform finishes.

Users can enhance their performance by leveraging data-driven insights, integrating innovative technologies, and adhering to regular maintenance schedules.

Eureka Machinery aims to address the unique needs of clients in the printing and packaging industry by providing valuable insights and advocating for modern technological solutions.

By investing in tailored training for operators and utilizing advanced performance analytics, businesses can improve their laminating processes and achieve higher-quality outputs.

Conclusion

So, there's this blog titled "Addressing Common Issues Faced by Laminator Users in Spanish Markets: A Data-Driven Perspective." It really digs into what local users in Spain are dealing with—things like inconsistent performance and tricky maintenance. The article sheds some light on how industries there are tweaking the way they use laminators to get better results. By analyzing trends and data, it offers some pretty neat insights into these problems, helping us come up with solutions that actually work for folks on the ground.

They also chat about best practices for keeping your laminator in good shape and troubleshooting common issues. And honestly, customer support plays a huge role in building trust with Spanish users. As a key player in the printing and packaging machinery world, SHANGHAI EUREKA MACHINERY IMP. & EXP. CO., LTD is all in on tackling these challenges head-on. Their goal? To provide quality solutions that really meet the needs of laminator users in Spain.

Blog Tags: