Top Automatic Box Folder Trends and Innovations to Watch for in 2025

Table of Contents

- Top Automatic Box Folder Trends and Innovations to Watch for in 2025

- Overview of the Automated Box Folder Market: Growth Statistics and Trends

- Key Technological Innovations Driving Automatic Box Folder Development

- Increasing Demand for Eco-Friendly Materials in Box Folding Solutions

- The Rise of Smart Automation and AI in Packaging Machinery

- Impact of E-commerce Growth on Automatic Box Folder Design and Functionality

- Regional Market Insights: North America vs. Europe in Box Folding Equipment

- Future Challenges in Sustainability and Efficiency for Box Folder Manufacturers

- Maximizing Efficiency in Box Production: Insights from Industry Reports on Automatic Folder Gluers and the JHX-2600B2-2 Model

- FAQS

- Conclusion

- Related Posts

As we look ahead to 2025, it’s clear that packaging technology is evolving pretty quickly, and the Automatic Box Folder is definitely at the forefront when it comes to boosting efficiency and innovation. This state-of-the-art machine is built to speed up and improve the accuracy of boxing things up, which is really important given how the global supply chain keeps growing and getting more complex. In today’s world, where being flexible and staying productive are super important, it’s a good idea for businesses to stay on top of the latest trends and tech in Automatic Box Folders — it could really give them a leg up.

We’re also seeing some pretty exciting stuff happening with smart tech like AI and machine learning making these machines even smarter. They help make the packaging process smoother, catch errors faster, and cut down on waste, which is great for businesses trying to be more eco-friendly and save some money. Plus, since online shopping continues to boom, there’s a bigger demand for boxes that are versatile and customizable. Designers and manufacturers are now exploring new shapes and automation features to keep up.

In this constantly changing market, it’s really important for everyone involved to keep an eye on these innovations if they want to stay competitive. By jumping on these new advancements, companies can boost their production and be ready for whatever challenges come next — all while keeping efficiency and sustainability in mind.

Top Automatic Box Folder Trends and Innovations to Watch for in 2025

In 2025, the landscape of automatic box folders is set to transform dramatically, driven by emerging trends and innovations. One significant trend is the integration of artificial intelligence (AI) into folding machines. AI technology enables these machines to adapt in real-time to different box styles and materials, optimizing the folding process for increased precision and speed. This adaptability not only improves efficiency but also reduces waste, making operations more sustainable.

Moreover, advancements in automation technology continue to make box folding processes more user-friendly. New interfaces that allow operators to easily program and adjust settings are becoming commonplace, reducing the learning curve for new employees and minimizing downtime. As these innovations evolve, they promise to enhance operational workflows and boost productivity across various industries.

Tips: To keep your business at the forefront of these trends, consider investing in training programs for staff to familiarize them with the latest technologies. Additionally, regularly evaluate your equipment to ensure it meets the evolving demands of your production needs, enabling smoother integration of future advancements. Embracing flexible and scalable solutions will provide your operations with the agility needed to adapt to changing market conditions.

Overview of the Automated Box Folder Market: Growth Statistics and Trends

The automated box folder market is poised for significant growth in the coming years, primarily driven by the increasing demand for efficiency in packaging processes. According to industry reports, the market is expected to reach a valuation of approximately $1.5 billion by 2025, growing at a compound annual growth rate (CAGR) of around 6.2%. This expansion is largely attributed to the rising trends in e-commerce, which require faster and more reliable packaging solutions to handle the growing volume of shipments.

Innovations in technology are playing a crucial role in shaping the future of automated box folders. Advances in robotics and artificial intelligence are facilitating the development of more sophisticated machines that can seamlessly integrate with existing production lines. For instance, the adoption of machine learning algorithms enables these systems to optimize the folding process, reducing material waste and improving overall efficiency. Furthermore, a recent survey indicates that approximately 65% of packaging companies plan to invest in automation technologies over the next five years, highlighting a clear shift toward modernizing operations to meet evolving market demands.

Top Automatic Box Folder Trends and Innovations to Watch for in 2025

Key Technological Innovations Driving Automatic Box Folder Development

In the rapidly evolving packaging industry, advancements in automatic box folder technology are significant not just for enhancing efficiency but also for reducing operational costs. Innovations centering around artificial intelligence (AI) and machine learning are transforming how these machines operate, enabling real-time adjustments and predictive maintenance. According to a recent industry report by Smithers Pira, the demand for automated packaging machinery is projected to grow at a CAGR of 4.6% through 2025, driven largely by the need for streamlined production processes and the increasing emphasis on sustainability.

Another critical trend reshaping the future of automatic box folders is the integration of IoT (Internet of Things) technology. Modern machines equipped with IoT capabilities can collect and analyze data from the production line, providing actionable insights that optimize performance and resource utilization. A report by Allied Market Research indicates that the global smart packaging market is expected to reach $31 billion by 2026, largely due to advancements in packaging automation. This level of connectivity not only enhances operational efficiency but also supports better inventory management and reduces waste, aligning with the industry's broader push towards sustainability.

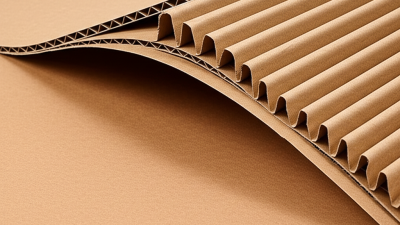

Increasing Demand for Eco-Friendly Materials in Box Folding Solutions

The increasing awareness of environmental issues has significantly influenced various industries, including packaging. In the realm of box folding solutions, there is a marked shift towards the use of eco-friendly materials. By 2025, businesses are expected to prioritize sustainable practices, adopting materials that are biodegradable, recyclable, and sourced from renewable resources. This demand is not merely a trend but a reflection of consumer preferences that increasingly favor products that align with eco-conscious values.

Advancements in technology are facilitating this transition towards greener solutions. Innovations in material science have led to the development of high-performance, eco-friendly alternatives that do not compromise on strength or durability. This evolution is crucial as companies seek to minimize their environmental footprint while still meeting the logistical demands of efficient packaging. The integration of automated box folding systems with these sustainable materials will likely become more prevalent, enabling manufacturers to streamline production processes while adhering to eco-friendly standards. As the industry innovates, the focus will be on creating packaging solutions that are both functional and environmentally responsible.

The Rise of Smart Automation and AI in Packaging Machinery

As the packaging industry continues to evolve, the integration of smart automation and artificial intelligence (AI) is set to revolutionize the way box folders operate. By 2025, we can expect to see a significant shift towards machines that not only automate the folding process but also incorporate advanced technologies to optimize production efficiency. These innovations include automated quality control systems that utilize AI-driven image recognition to detect defects in real time, ensuring that only the highest quality products make it to the end of the supply chain.

Moreover, the increasing demand for customized packaging solutions is pushing manufacturers to adopt flexible automation systems. These systems will leverage AI algorithms to adapt quickly to varying production needs, allowing for quick adjustments in folding styles and sizes without the need for extensive reconfiguration. This trend not only enhances flexibility but also reduces downtime, enabling manufacturers to meet dynamic market demands efficiently. As smart automation becomes more prevalent, we can anticipate a future where packaging machinery is more intelligent, responsive, and capable of self-optimizing to drive greater productivity and sustainability across the industry.

Impact of E-commerce Growth on Automatic Box Folder Design and Functionality

The surge of e-commerce has significantly influenced the design and functionality of automatic box folders, making them crucial for businesses aiming to boost their packaging efficiency. With online shopping becoming the norm, the demand for versatile and efficient packaging solutions has skyrocketed. Automatic box folders are adapting by integrating technology that allows for faster processing and customization, helping companies keep pace with fluctuating online order volumes. This evolution not only improves operational efficiency but also enhances the customer experience by ensuring that products arrive quickly and securely.

When implementing automatic box folders in an e-commerce environment, here are a few tips to consider:

- First, opt for machines that can handle a variety of box sizes and styles to accommodate diverse product offerings.

- Second, look for systems that feature advanced sensors and automation to minimize human error and reduce labor costs.

- Lastly, invest in models that offer real-time data analytics to track performance and optimize packing processes, thereby supporting continuous improvement efforts.

As e-commerce expands, the shift towards sustainable practices is also shaping box folder innovations. Companies are increasingly focusing on eco-friendly materials and designs, aligning their packaging solutions with the growing consumer preference for sustainability. By prioritizing these advancements in automatic box folder technology, businesses not only meet the rising expectations of the market but also contribute positively to environmental conservation.

Regional Market Insights: North America vs. Europe in Box Folding Equipment

The box folding equipment market is witnessing significant shifts between the North American and European regions, driven by varying consumer demands, technological advancements, and regulatory environments. In North America, there is a marked increase in demand for automation and efficiency in packaging processes, spurred by e-commerce growth and the need for faster production line speeds. Manufacturers are investing heavily in state-of-the-art automatic box folder technologies that enhance throughput and reduce labor costs. Moreover, sustainability is becoming a priority, with companies aiming to minimize waste and optimize packaging materials.

In contrast, Europe's approach to box folding equipment is influenced by a strong emphasis on environmental regulations and standards. European manufacturers are at the forefront of integrating eco-friendly materials and energy-efficient systems into their machinery. The market is also seeing a rise in the demand for customization, with businesses seeking versatile solutions that can accommodate various box sizes and types while maintaining sustainability goals. As the competition intensifies between the regions, innovations in smart technologies, such as IoT-enabled machines, are poised to redefine the landscape, offering enhanced connectivity and real-time data analytics for optimal operations.

Future Challenges in Sustainability and Efficiency for Box Folder Manufacturers

As the packaging industry evolves, box folder manufacturers face significant future challenges in sustainability and efficiency. According to a recent market analysis by Smithers Pira, the global demand for sustainable packaging solutions is projected to grow at a compound annual growth rate (CAGR) of 5.7% from 2021 to 2026, signifying that manufacturers need to prioritize environmental considerations in their production processes. The trend towards eco-friendly materials, such as biodegradable and recyclable options, is gaining traction, compelling manufacturers to innovate their box folding technologies to accommodate these materials without compromising on speed or efficiency.

Additionally, efficiency remains a critical focus area as market competition intensifies. A report by The Freedonia Group states that advancements in automation could lead to improvements in productivity by up to 30% in the box folder sector by 2025. This will necessitate the integration of smart technologies, such as AI and IoT, to optimize operations and manage supply chains more effectively. However, implementing these technologies requires significant investment and a skilled workforce, which presents a challenge for many manufacturers. Hence, balancing sustainable practices while enhancing operational efficiency will be the defining challenge for box folder manufacturers in the coming years.

Maximizing Efficiency in Box Production: Insights from Industry Reports on Automatic Folder Gluers and the JHX-2600B2-2 Model

The manufacturing industry is increasingly recognizing the importance of automating processes to enhance efficiency in box production. One of the key advancements in this area is the use of automatic folder gluers, particularly models like the JHX-2600B2-2. Designed specifically for handling a variety of corrugated sheets, including A.B.C.AB. flute and 3-ply configurations, this equipment not only streamlines operations but also ensures high-quality output.

The JHX-2600B2-2 model boasts impressive specifications, accommodating maximum sheet sizes of 2500*900mm and minimum sizes of 680*300mm. The machine features an advanced feeding system with eight adjustable suctions at the leading edge feeder, which allows for precise material handling. Furthermore, the strengthened folding section is designed to minimize waste, while the arm sorting function facilitates rapid job changes and neat sheet alignment, crucial for maintaining consistent production flow.

Incorporating cutting-edge technology, the machine is powered by a servo motor and supported by a user-friendly PLC and human-machine interface. This setup enables stepless speed regulation and secondary correction, significantly enhancing the automation process. With fast carton-forming speeds and precise operations, the JHX-2600B2-2 is an excellent choice for companies aiming to maximize their productivity and maintain high standards in packaging solutions.

FAQS

: One significant trend is the integration of artificial intelligence (AI) into folding machines, which allows them to adapt in real time to different box styles and materials, optimizing the folding process for precision and speed.

AI technology improves efficiency, reduces waste, and enhances sustainability by enabling machines to adapt to various box styles and materials in real time.

New interfaces are being developed that allow operators to easily program and adjust settings, which reduces the learning curve for new employees and minimizes downtime.

The automated box folder market is expected to reach a valuation of approximately $1.5 billion by 2025, growing at a compound annual growth rate (CAGR) of around 6.2%.

The rising trends in e-commerce require faster and more reliable packaging solutions to handle the growing volume of shipments, driving automation in the packaging industry.

Innovations in robotics and AI allow for the creation of more sophisticated machines that can integrate with existing production lines and optimize the folding process effectively.

Smart automation revolutionizes box folders by incorporating advanced technologies for optimizing production efficiency and implementing automated quality control systems.

Flexible automation systems enable quick adjustments in folding styles and sizes, allowing manufacturers to adapt to varying production needs without extensive reconfiguration.

Approximately 65% of packaging companies plan to invest in automation technologies over the next five years, indicating a shift towards modernizing operations.

Future packaging machinery is expected to be more intelligent, responsive, and capable of self-optimizing to drive greater productivity and sustainability in the industry.

Conclusion

The upcoming trends and innovations in the Automatic Box Folder market for 2025 highlight significant growth driven by technological advancements and changing consumer demands. Key developments include the integration of smart automation and artificial intelligence, which enhance efficiency and precision in box folding processes. Moreover, the increasing demand for eco-friendly materials reflects a shift towards sustainable packaging solutions, addressing environmental concerns.

Additionally, the rise of e-commerce continues to impact the design and functionality of Automatic Box Folders, necessitating more versatile and efficient equipment to accommodate varying box sizes and types. Regional insights suggest differences in market dynamics between North America and Europe, with each facing unique challenges in sustainability and manufacturing efficiency. This ongoing evolution indicates a promising future for Automatic Box Folder manufacturers who can adapt to these trends and consumer preferences.

Related Posts

-

10 Best Automatic Box Folders for Efficient Packaging Solutions in 2023

-

What is an Automatic Cardboard Box Making Machine and How Does It Revolutionize Packaging?

-

5 Essential Tips for Maximizing Efficiency with Automatic Bottom Box Solutions in 2023

-

What is a Stack Paper Cutter? Benefits, Features, and Buying Guide

-

Exploring Competitive Edge: Cutter Price Insights at the 138th Canton Fair 2025

-

Exploring Options for the Viena Seja Gofrētā Kartona Mašīna in Packaging Solutions

Blog Tags: