An automatic flatbed die-cutting machine with blanking uses a flat platen and die to cut and remove shapes from materials like paper, cardboard, plastic, and thin metal sheets. You get both die-cutting and blanking in one seamless automated process. This technology delivers high speed and precision—up to 8,000 sheets per hour—while reducing waste and errors. Many industries such as packaging, printing, and labeling rely on these machines to boost efficiency, maintain quality, and handle complex jobs with ease.

· Automatic flatbed die-cutting machines with blanking combine cutting and waste removal in one fast, precise process.

· These machines handle many materials like paper, cardboard, plastic, and foam with high accuracy and less waste.

· Automation reduces manual work, speeds up production, and keeps quality consistent for small or large jobs.

· Built-in features like digital controls, quick die changes, and safety systems make operation easy and reliable.

· They serve many industries including packaging, labels, and automotive parts, boosting efficiency and product quality.

How It Works

Core Mechanism

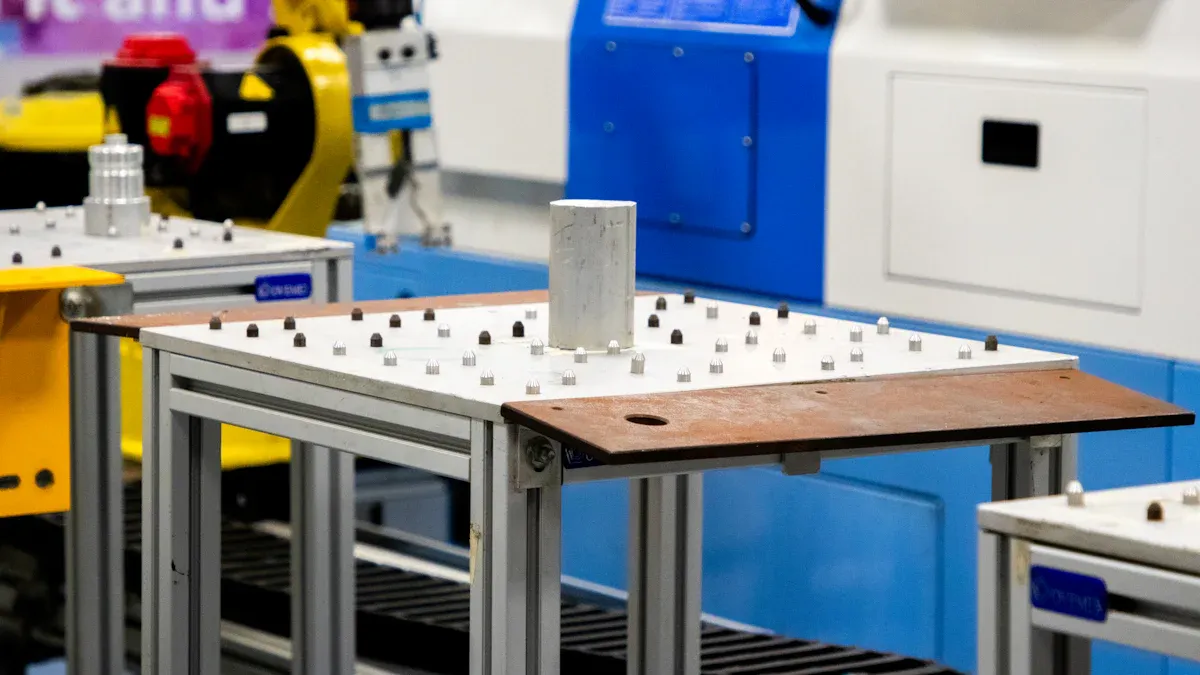

You will find that an automatic flatbed die-cutting machine uses a combination of advanced mechanical and electronic systems to deliver precise and efficient cutting. The main components work together to ensure each sheet is handled with care and accuracy.

· The machine uses a worm and worm gear transmission with a crankshaft. This setup gives you high cutting pressure and long-lasting durability.

· A high-precision intermittent mechanism keeps the cutting process steady and accurate.

· The feeding system, based on European technology, uses adjustable suction to move paper smoothly and precisely.

· Non-stop feeding, pre-stacking, and delivery devices help you keep production running without delays.

· Automatic pressure adjustment with a digital display lets you control and monitor the cutting force easily.

· The die frame and baseplate are designed for quick installation and adjustment. Pneumatic die locking saves you time and keeps the die secure.

· Paper positioning uses front lay, side lay, and fine-tuning devices. Optoelectronic position control helps reduce waste by making sure each sheet is in the right place.

· The electrical control system uses high-quality imported parts and a touch screen interface. You can monitor the machine in real time and solve problems quickly.

· A cycling cooling oil supply system keeps moving parts lubricated, which increases the machine’s lifespan.

When you look at the die-cutting process itself, you see how hydraulic presses and steel rule dies play a key role:

- Steel rule dies are thin steel blades shaped into the form you need and set into a strong board.

- The hydraulic press pushes the die into the material, cutting it cleanly.

- This method works well for materials like foam, film, rubber, foil, and adhesive tape.

- The die base is cut by laser or water jet to fit the steel rule blade.

- Rubber or foam between the steel rules helps push out waste after cutting.

- Hydraulic presses can be manual or automatic. In automatic flatbed machines, the material feeds from rolls, and finished products come out on conveyors.

- Adjustable stroke height and tonnage make sure the die board and cutting surface stay parallel, giving you uniform cuts every time.

- Quick-change tooling and optical registration systems help you switch jobs fast and keep cuts precise.

- Roll-feed transport and micrometer-stop depth control protect the die and keep cutting quality high.

Blanking Integration

Blanking is the stage where the machine removes waste and stacks the finished shapes automatically. You do not need to strip the waste by hand, which saves you time and effort.

- The blanking system uses robot arms and automatic stack loaders to separate cut shapes from waste.

- Waste scraps fall into special discharge channels during stripping, keeping the machine clean and safe.

- A high-precision servo paper feeding system and PLC control system make sure each sheet moves smoothly and lands in the right spot.

- Programmable controls let you run the machine automatically, showing you the status and product details on a screen.

- Scraps and finished pieces go to different areas, so you can remove them easily and automatically.

- By adding blanking to the die-cutting line, you streamline production, reduce manual labor, and boost efficiency.

Tip: When you use an automatic flatbed die-cutting machine with blanking, you can handle large jobs quickly and with less waste. This technology helps you keep your workspace clean and your output consistent.

Speed and Machine Examples

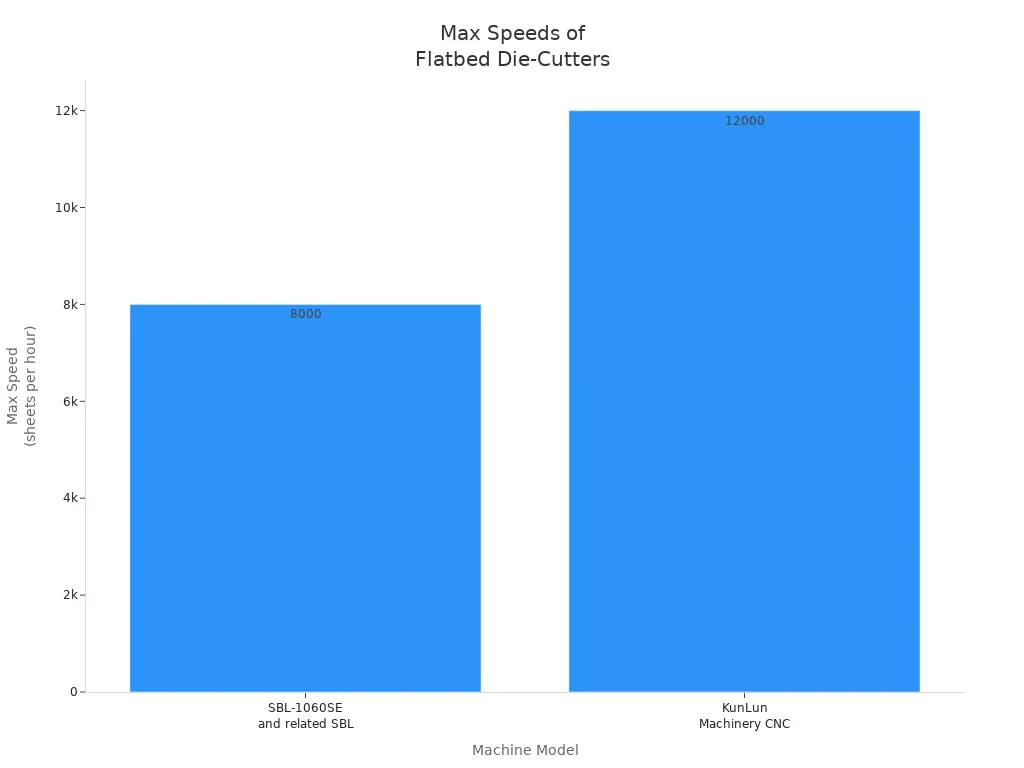

You can see how fast these machines work by looking at some leading models:

| Machine Model | Maximum Speed (sheets per hour) | Notes |

|---|---|---|

| KunLun Machinery CNC die-cutting machine | Up to 12,000 | Mass-produced in China, global leader |

| SBL-1060SE and related SBL series | Up to 8,000 | Automatic flatbed die cutters with blanking or stripping |

| BHT-1060SCE | N/A | No explicit speed data found |

| BOBST MASTERCUT | N/A | No explicit speed data found |

You can rely on automatic flatbed machines like the SBL-1060SE for up to 8,000 sheets per hour. If you need even more speed, the KunLun Machinery CNC die-cutting machine can reach up to 12,000 sheets per hour. These machines help you meet high production demands while keeping quality and precision at the highest level.

Key Operations

Cutting & Creasing

You start the process with cutting and creasing. The machine presses a die board with sharp blades and creasing tools onto your material. This die board can have different setups, such as simple or combination dies, depending on your needs. The process includes several steps:

1. Design and Preparation: You create the shape or pattern using software or a physical die. 2. Material Setup: You place and secure the material on the flatbed so it does not move. 3. Die Placement: You position the custom steel blade die on top of the material. 4. Cutting Process: The machine applies pressure to cut through the material and add creases. 5. Removal and Finishing: You remove the cut pieces and may add scores or perforations.

Creasing lines help you fold or tear the material easily. You should keep holes away from score lines to prevent unwanted tearing. Tabs can help keep your product strong and in one piece. These steps give you precise, high-quality results every time.

Stripping & Blanking

Stripping and blanking remove waste and separate finished pieces. You do not need to do this by hand. The machine uses advanced technology to make this step fast and accurate. Here is how it works:

| Process Section | Description and Technologies Used |

|---|---|

| Stripping Section | The machine uses optimized motion to strip waste. A lighter drive structure reduces wear on parts. |

| Die-cutting Section | Central line registration and pneumatic locking make die changes easy. Automatic pressure control gives you exact cuts. The frame design keeps everything flat and accurate. |

| Delivery Section | Pneumatic joggling and a servo brush device help stack finished pieces neatly. You can adjust settings for different materials. |

Computerized controls, digital pressure adjustment, and optoelectronic sensors keep everything running smoothly. You get less waste and more reliable results.

Embossing & Debossing

Embossing and debossing add texture to your products. Embossing raises parts of the material, while debossing presses them down. You use special dies for these effects. The machine presses the die into the material with controlled force. You can create logos, patterns, or text that stand out. This step gives your packaging or labels a premium look and feel. You can combine embossing or debossing with cutting and creasing in one pass, saving you time and effort.

Tip: Try embossing or debossing to make your products more attractive and memorable.

Automatic Flatbed Technology

Precision & Reliability

You can count on automatic flatbed machines for high precision and reliable performance. These machines use advanced automation features that help you get consistent results every time. Here are some key features that boost accuracy and reliability:

- Fully automatic feeding and stripping systems keep your workflow smooth and reduce manual labor.

- Precise cut-to-print registration adjustments let you match each job’s needs, so you get perfect cuts.

- Automatic waste removal keeps your workspace clean and your process efficient.

- User-friendly touch screen controls make operation simple and help prevent mistakes.

- Remote online diagnostics allow you to solve problems quickly and keep your machine running.

- Quick die-form changes, often under four minutes, help you switch jobs fast and avoid downtime.

- High-definition cameras and software systems ensure exact material alignment.

- Continuous loading and processing support uninterrupted production.

Modern automatic flatbed machines can achieve cutting tolerances as tight as ±0.1 millimeters. This level of accuracy is important for packaging and specialty products. You get less waste and more consistent quality with every run.

Material Versatility

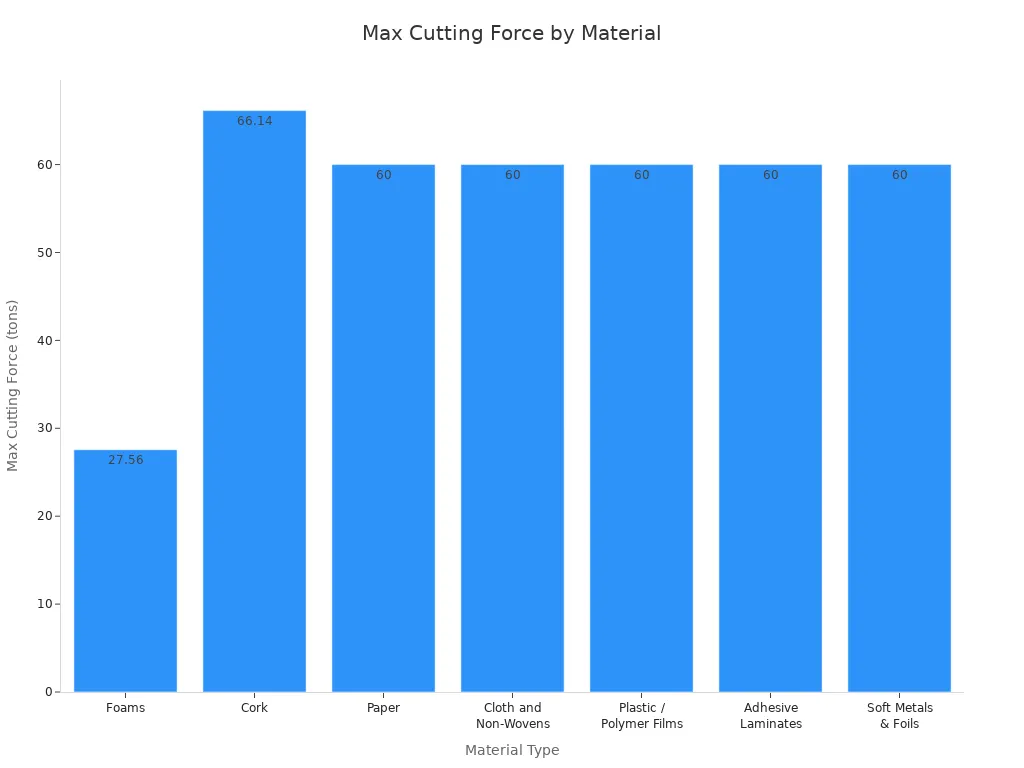

You can use automatic flatbed machines with a wide range of materials. These machines handle everything from thin paper to thick corrugated board and even plastics. The strong cutting force—up to 300 tons—means you can process tough jobs with ease.

| Material Type | Maximum Thickness | Cutting Force |

|---|---|---|

| Paper | Minimum 80 g/m² | Up to 300 tons |

| Cardboard | Maximum 2000 g/m² | Up to 300 tons |

| Corrugated Board | Up to 4 mm | Up to 300 tons |

| Solid Board | Not specified | Up to 300 tons |

| Plastic | Not specified | Up to 300 tons |

You can also cut foams, cork, cloth, non-wovens, adhesive laminates, and soft metals. The machine’s flexibility lets you take on many types of projects without changing equipment.

Efficiency & Quality

Speed & Throughput

You can achieve impressive speeds with automatic flatbed die-cutting machines. Most models run between 4,000 and 6,000 sheets per hour. Some advanced machines, like the Heidelberger Speedmaster XL 105-DD, reach up to 10,000 sheets per hour. This high throughput means you finish large jobs quickly and keep up with tight deadlines. When you use these machines, you also benefit from shorter setup times. You do not need to stop production often, so you get more done in less time. This speed gives you a big advantage over manual or semi-automatic machines, which work much slower and require more hands-on effort.

Consistency & Waste Reduction

You get consistent results every time you use an automatic flatbed machine. Programmable settings and digital controls help you keep each cut precise. You do not have to worry about mistakes from manual handling. These machines use sensors and real-time monitoring to check every sheet. This technology helps you reduce waste because you catch errors early. You also use less material since the machine cuts with high accuracy. When you produce less waste, you save money and help the environment.

Cost-Effectiveness

You save money in several ways when you choose automatic flatbed die-cutting machines. These machines lower labor costs because you need fewer workers to run them. You also finish jobs faster, which means you can take on more work. Many companies see efficiency improve by up to 50% after switching to automation. You also reduce waste and improve product quality, which boosts your reputation. Most businesses recover their investment in three to five years. This quick return comes from higher output, lower costs, and less waste. Over time, you see better profits and steady growth.

| Benefit | Impact on Your Business |

|---|---|

| Lower labor costs | Fewer workers needed |

| Faster production | More jobs completed |

| Less waste | Save money and materials |

| Quick ROI | Payback in 3-5 years |

Applications

Packaging

You can use automatic flatbed die-cutting machines with blanking for many packaging needs. These machines help you create packaging that looks good and works well. You can make:

- Corrugated boxes with precise shapes and sizes

- Folding cartons with strong folds and clean lines

- Custom packaging with unique shapes and designs

- Rigid boxes for luxury products

- Paper bags from both rolls and sheets

You get packaging that stands out and protects your products. The machines let you adjust pressure and speed for each material, so you waste less and keep quality high. You can handle both small and large orders with the same machine. User-friendly controls and fast setup save you time and reduce mistakes.

Tip: When you match machine settings to your materials, you get better results and less waste.

Labels

You can produce many types of labels with these machines. Flatbed die-cutting works well for self-adhesive labels, bottle labels, food packaging labels, and medicine pack labels. You can cut custom shapes and sizes with high precision—up to ±0.10mm. The machines support both short and long runs, making them great for custom orders or high-volume jobs.

- Labels for bottles, food, cosmetics, and medicine

- Printed and plain label rolls

- Custom shapes, hole punching, and hot stamping

- Medium to high production speeds (up to 300 cuts per minute)

You get clean edges and sharp designs every time. Automation reduces errors and keeps your labels consistent. The machines also work with thick or layered materials, so you can make durable labels for many uses.

Industrial Uses

You can use automatic flatbed die-cutting machines in many industries beyond packaging. In automotive manufacturing, you can make adhesive tapes for bonding, damping, and sealing. Electronics companies use these machines to cut special pads, insulation, and EMI shielding materials. You can also produce sound-absorbing and shock-absorbing parts for cars and devices.

- Adhesive tapes for automotive parts

- Conductive and insulating materials for electronics

- Fireproof paper, copper foil, and aluminum foil

- Noise reduction and cushioning parts

These machines help you work faster and safer. You get reliable, high-quality parts that meet strict standards. Automation lets you handle complex jobs with less effort.

Note: Automatic flatbed die-cutting machines give you the flexibility to serve many industries with one solution.

You gain many advantages when you choose automatic flatbed die-cutting machines with blanking:

- You get high precision and repeatable cuts for foam, rubber, plastics, and films.

- You see minimal waste and clean, sharp edges on every part.

- You can handle both thick and thin materials with short setup times.

- Automation and blanking features boost your productivity and keep quality consistent.

If you want to learn more, Market Size and Trends offers expert research and consultation. Their team provides detailed reports and guidance to help you make smart decisions about die-cutting technology.

FAQ

What materials can you process with an automatic flatbed die-cutting machine?

You can process paper, cardboard, corrugated board, plastic, foam, and thin metal sheets. These machines handle both thin and thick materials. You can switch between different jobs quickly.

How does blanking improve your production process?

Blanking removes waste and stacks finished pieces automatically. You do not need to strip waste by hand. This feature saves you time and keeps your workspace clean.

Tip: Blanking helps you finish large jobs faster and with less effort.

Can you use these machines for small or custom orders?

Yes, you can handle both small and large orders. You can adjust the machine for custom shapes and sizes. Quick setup and digital controls make it easy to switch between jobs.

What maintenance do you need for these machines?

You should clean moving parts, check for wear, and keep the machine lubricated. Regular inspections help you avoid breakdowns. Many machines have alerts to remind you about maintenance.

Are automatic flatbed die-cutting machines safe to use?

Yes, these machines have safety features like emergency stops, guards, and sensors. You should follow the safety instructions and wear protective gear. Training helps you use the machine safely every day.

Post time: Apr-07-2025