High Quality Flatbed Diecutting - MWZ1620N Lead Edge Automatic Die Cutting Machine with Full Stripping Section – Eureka

High Quality Flatbed Diecutting - MWZ1620N Lead Edge Automatic Die Cutting Machine with Full Stripping Section – Eureka Detail:

| Model | MWZ1620N |

| Max. Paper Size | 1650*1210 mm |

| Min. Paper Size | 650*500 mm |

| Max. Cutting Size | 1620*1190 mm |

| Max. Cutting Pressure | 300×104 N |

| Stock Range | 1mm ≤ Corrugated board ≤ 8.5 mm |

| Die Cutting Accuracy | ±0.5 mm |

| Max. Mechanical Speed | 4000 s/h |

| Pressure adjustment | ±1 mm |

| Minimum Front Margin | 9 mm |

| Inner Chase Size | 1650*1220 mm |

| Total Power | 34.6 KW |

| Machine Dimension | 8368*2855*2677 mm (exclude the work platform, turning frame) |

| Machine Dimension | 10695*2855*2677 mm (include the platform) |

| Total Weight | 27t |

|

No. |

Main Parts |

Brand |

Supplier |

|

1 |

Main driving chain |

Renold |

England |

|

2 |

Bearing |

NSK |

Japan |

|

3 |

Inverter |

Yaskawa |

Japan |

|

4 |

Electrical components |

Omron/Schneider/Siemens |

Japan/Germany |

|

5 |

PLC |

Siemens |

Germany |

|

6 |

Pneumatic Clutch |

OMPI |

Italy |

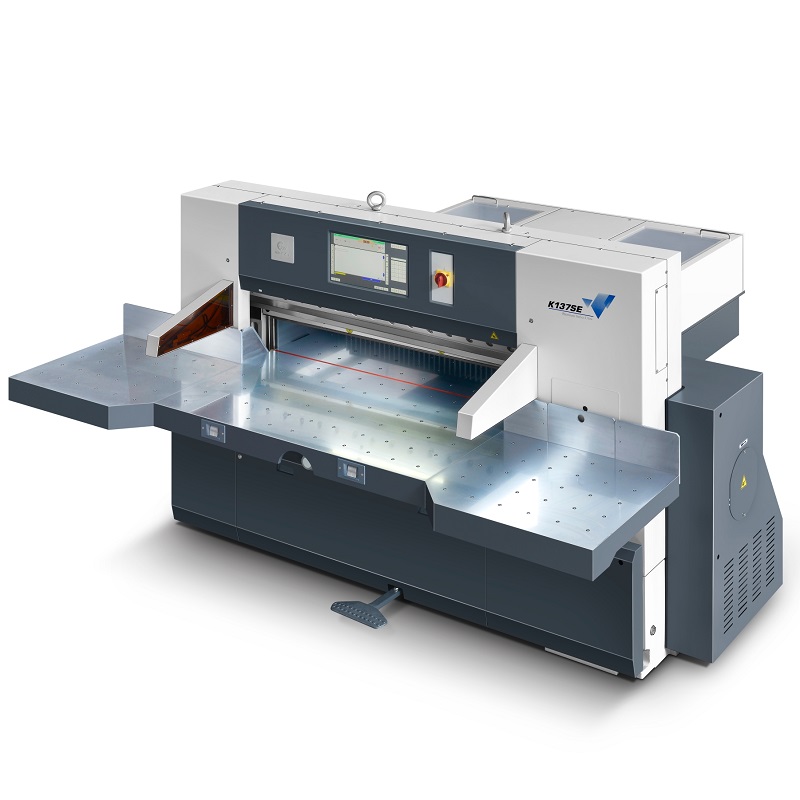

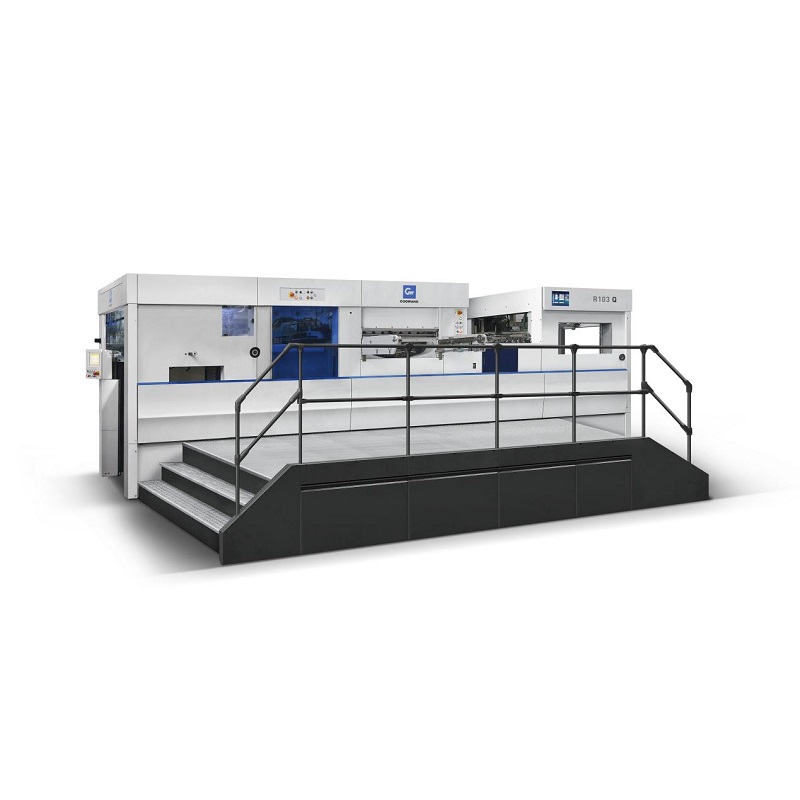

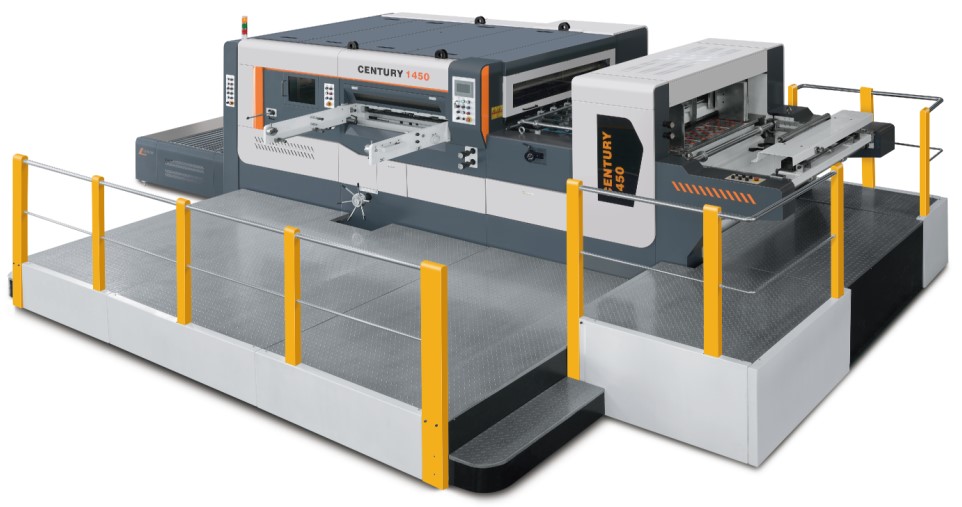

Product detail pictures:

Related Product Guide:

Our company sticks to the principle of "Quality is the life of the company, and reputation is the soul of it" for High Quality Flatbed Diecutting - MWZ1620N Lead Edge Automatic Die Cutting Machine with Full Stripping Section – Eureka , The product will supply to all over the world, such as: Seychelles, Rotterdam, Munich, Now, we professionally supplies customers with our main products And our business is not only the "buy" and "sell", but also focus on more. We target to be your loyal supplier and long-term cooperator in China. Now, We hope to be the friends with you.

Cooperate with you every time is very successful, very happy. Hope that we can have more cooperation!

Write your message here and send it to us