Fast delivery Flat Bed Die - MWZ1620N Lead Edge Automatic Die Cutting Machine with Full Stripping Section – Eureka

Fast delivery Flat Bed Die - MWZ1620N Lead Edge Automatic Die Cutting Machine with Full Stripping Section – Eureka Detail:

| Model | MWZ1620N |

| Max. Paper Size | 1650*1210 mm |

| Min. Paper Size | 650*500 mm |

| Max. Cutting Size | 1620*1190 mm |

| Max. Cutting Pressure | 300×104 N |

| Stock Range | 1mm ≤ Corrugated board ≤ 8.5 mm |

| Die Cutting Accuracy | ±0.5 mm |

| Max. Mechanical Speed | 4000 s/h |

| Pressure adjustment | ±1 mm |

| Minimum Front Margin | 9 mm |

| Inner Chase Size | 1650*1220 mm |

| Total Power | 34.6 KW |

| Machine Dimension | 8368*2855*2677 mm (exclude the work platform, turning frame) |

| Machine Dimension | 10695*2855*2677 mm (include the platform) |

| Total Weight | 27t |

|

No. |

Main Parts |

Brand |

Supplier |

|

1 |

Main driving chain |

Renold |

England |

|

2 |

Bearing |

NSK |

Japan |

|

3 |

Inverter |

Yaskawa |

Japan |

|

4 |

Electrical components |

Omron/Schneider/Siemens |

Japan/Germany |

|

5 |

PLC |

Siemens |

Germany |

|

6 |

Pneumatic Clutch |

OMPI |

Italy |

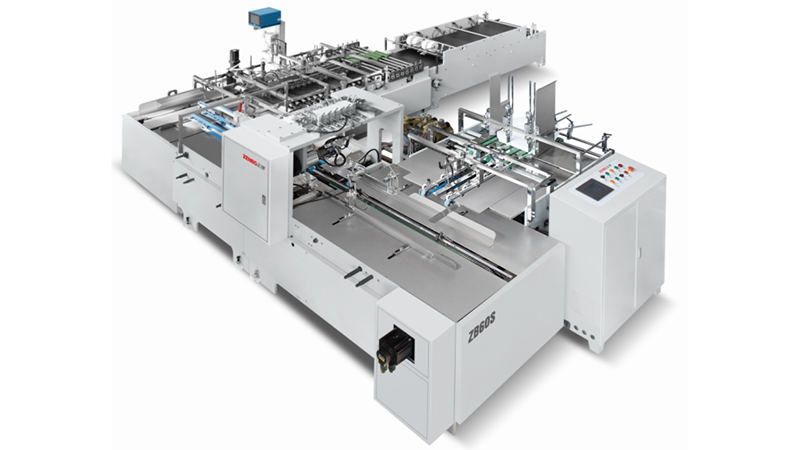

Product detail pictures:

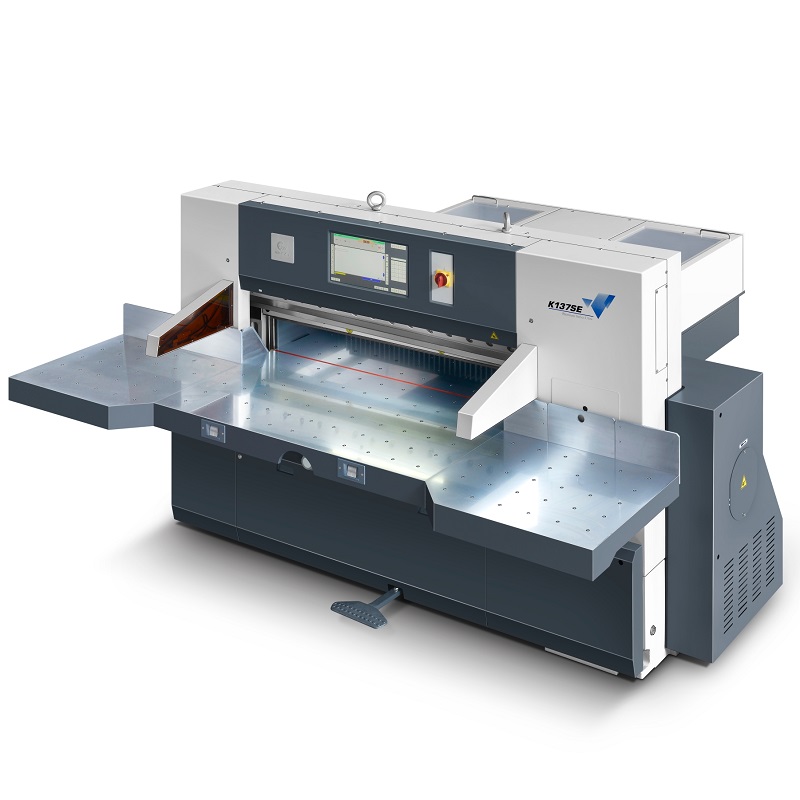

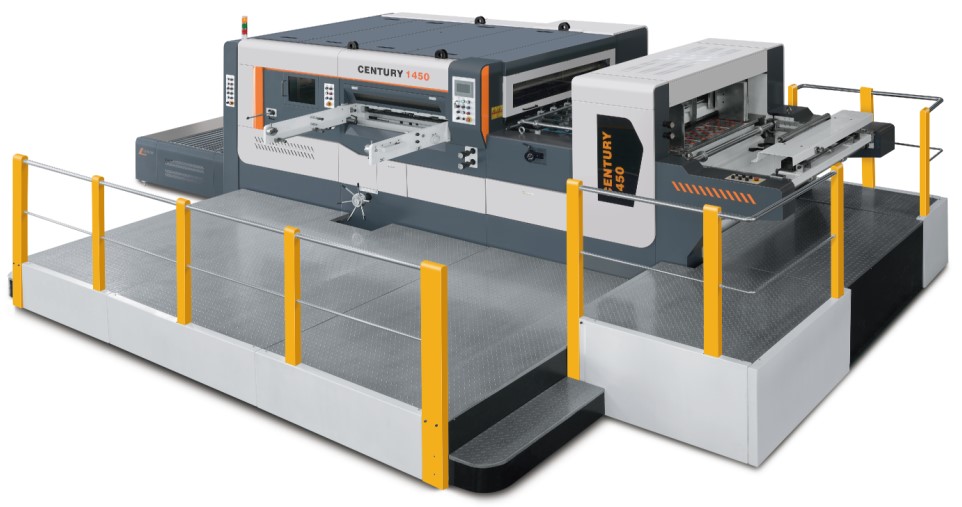

Related Product Guide:

We have now probably the most innovative production equipment, experienced and qualified engineers and workers, regarded high quality control systems and also a friendly expert income team pre/after-sales support for Fast delivery Flat Bed Die - MWZ1620N Lead Edge Automatic Die Cutting Machine with Full Stripping Section – Eureka , The product will supply to all over the world, such as: Casablanca, California, Riyadh, We are your reliable partner in international markets with the best quality products. Our advantages are innovation, flexibility and reliability which have been built during the last twenty years. We focus on providing service for our clients as a key element in strengthening our long-term relationships. Our continual availability of high grade products in combination with our excellent pre-sales and after-sales service ensures strong competitiveness in an increasingly globalized market.

The product manager is a very hot and professional person, we have a pleasant conversation, and finally we reached a consensus agreement.

Write your message here and send it to us