China New Product Flute laminator – FMZ-1480/1650 Automatic Flute Laminating machine for cardboard corrugated – Eureka

China New Product Flute laminator – FMZ-1480/1650 Automatic Flute Laminating machine for cardboard corrugated – Eureka Detail:

Automatic feeding for top sheet and bottom sheet.

Integrated control with PLC can provide easy operation & trouble shot during production. Safety for user is considered and widely used in the machine design.

Famous international brand components like bearing, electrical parts are used in the critical functioning parts of the machine to have stable running.

Elastic front register positioning, bottom paper will not exceed the top paper. The distance between top paper and bottom paper could be adjusted. Top paper correction system.

Suitable for paperboard with A/B/C/D/E flute corrugated cardboard.

Options: suitable for cardboard with cardboard more than 300gsm

| Model | FMZ-1480 | FMZ-1650 |

| Max. sheet size | 1300×1480mm | 1650×1650mm |

| Min. sheet size | 500*400mm | 500*400mm |

| Power consumption | 25kw | 26kw |

| Top paper weight | 200-450gsm | 200-450gsm |

| Laminating tolerance | ±1.5MM | ±1.5MM |

| Max.working speed | 7000sph | 7000sph |

| name | brand | note |

| MAIN MOTOR | CHINA | |

| FEEDER MOTOR | CHINA | |

| ADJUST MOTOR | CHINA | |

| FEEDING BELT | CHINA | |

| VACCUM PUMP | CHINA | |

| VORTEX PUMP | CHINA | |

| BEARING | CHINA | |

| PRESSING PART BELT | CHINA | |

| INVERTER | SCHNEIDER | |

| CONTACTOR | CHINA | |

| SWITCH POWER | OMRON | |

| SENSOR | OMRON | |

| PLC | SCHNEIDER | |

| TOUCH SCREEN | SCHNEIDER | |

| LIFT BUTTON | SCHNEIDER |

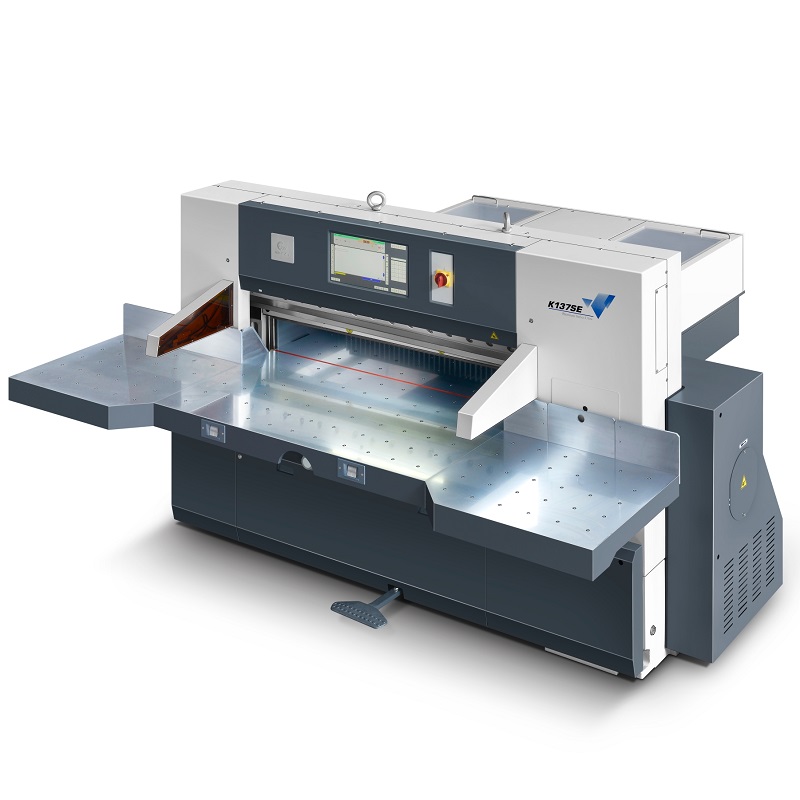

Product detail pictures:

Related Product Guide:

We will devote ourselves to providing our esteemed customers with the most enthusiastically thoughtful services for China New Product Flute laminator – FMZ-1480/1650 Automatic Flute Laminating machine for cardboard corrugated – Eureka , The product will supply to all over the world, such as: Bangladesh, Colombia, Qatar, With more and more Chinese products and solutions around the world, our international business is developing rapidly and economic indicators big increase year by year. We have enough confidence to supply you both better solutions and service, because we've been more and more powerful, specialist and experience in domestic and international.

The customer service reprersentative explained very detailed, service attitude is very good, reply is very timely and comprehensive, a happy communication! We hope to have a opportunity to cooperate.

Write your message here and send it to us