China New Product Flute laminator – FMZ-1480/1650 Automatic Flute Laminating machine for cardboard corrugated – Eureka

China New Product Flute laminator – FMZ-1480/1650 Automatic Flute Laminating machine for cardboard corrugated – Eureka Detail:

Automatic feeding for top sheet and bottom sheet.

Integrated control with PLC can provide easy operation & trouble shot during production. Safety for user is considered and widely used in the machine design.

Famous international brand components like bearing, electrical parts are used in the critical functioning parts of the machine to have stable running.

Elastic front register positioning, bottom paper will not exceed the top paper. The distance between top paper and bottom paper could be adjusted. Top paper correction system.

Suitable for paperboard with A/B/C/D/E flute corrugated cardboard.

Options: suitable for cardboard with cardboard more than 300gsm

| Model | FMZ-1480 | FMZ-1650 |

| Max. sheet size | 1300×1480mm | 1650×1650mm |

| Min. sheet size | 500*400mm | 500*400mm |

| Power consumption | 25kw | 26kw |

| Top paper weight | 200-450gsm | 200-450gsm |

| Laminating tolerance | ±1.5MM | ±1.5MM |

| Max.working speed | 7000sph | 7000sph |

| name | brand | note |

| MAIN MOTOR | CHINA | |

| FEEDER MOTOR | CHINA | |

| ADJUST MOTOR | CHINA | |

| FEEDING BELT | CHINA | |

| VACCUM PUMP | CHINA | |

| VORTEX PUMP | CHINA | |

| BEARING | CHINA | |

| PRESSING PART BELT | CHINA | |

| INVERTER | SCHNEIDER | |

| CONTACTOR | CHINA | |

| SWITCH POWER | OMRON | |

| SENSOR | OMRON | |

| PLC | SCHNEIDER | |

| TOUCH SCREEN | SCHNEIDER | |

| LIFT BUTTON | SCHNEIDER |

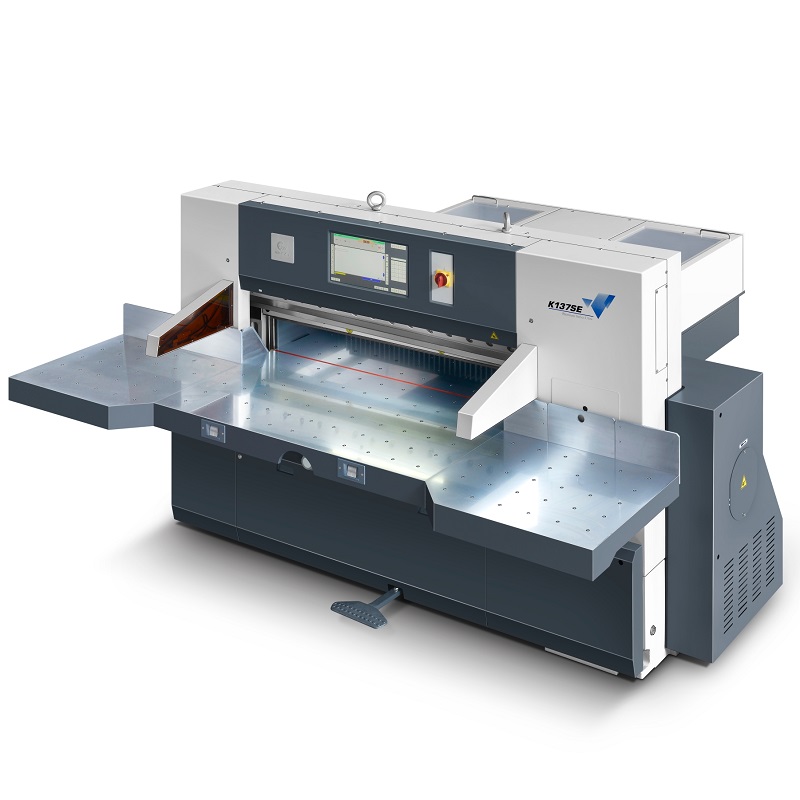

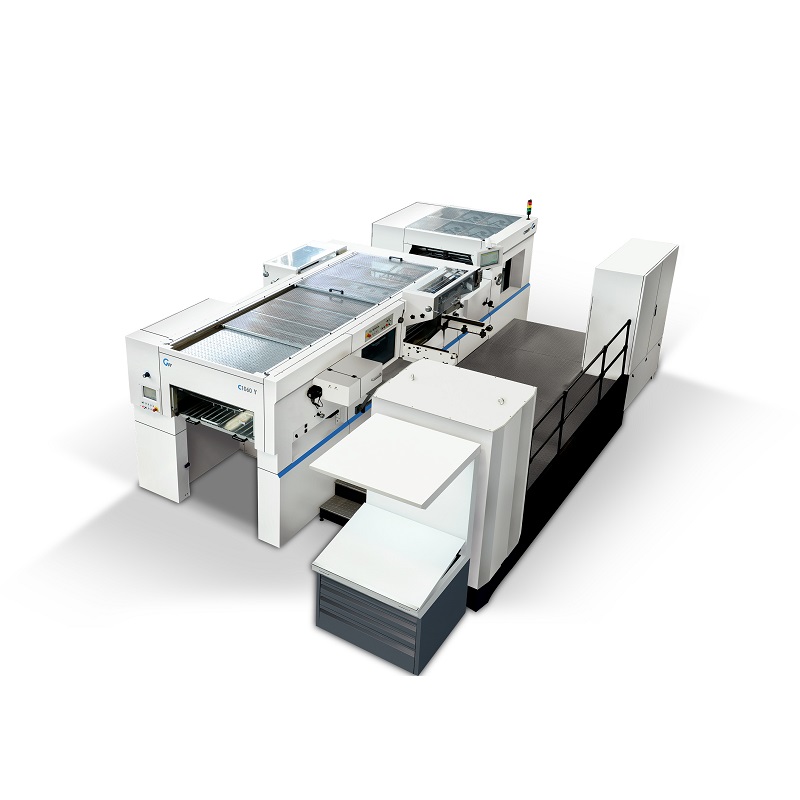

Product detail pictures:

Related Product Guide:

The organization keeps for the procedure concept "scientific administration, superior quality and effectiveness primacy, shopper supreme for China New Product Flute laminator – FMZ-1480/1650 Automatic Flute Laminating machine for cardboard corrugated – Eureka , The product will supply to all over the world, such as: Australia, San Diego, panama, There are advanced producing & processing equipment and skilled workers to ensure the products with high quality. We have found an excellent before-sale, sale, after-sale service to ensure the customers that could rest assured to make orders. Until now our products are now moving on fast and very popular in South America, East Asia, the Middle east, Africa, etc.

In our cooperated wholesalers, this company has the best quality and reasonable price, they are our first choice.

Write your message here and send it to us