How to Transform Your Branding with Flexo-Graphics Techniques

Table of Contents

- Understanding Flexo-Graphics: An Overview of Techniques and Applications

- The Role of Color in Flexo-Graphics: Enhancing Brand Identity

- Surface Textures and Effects: Making Your Branding Stand Out

- Cost Efficiency of Flexo-Graphics Compared to Other Print Methods

- Real-Life Case Studies: Successful Branding through Flexo-Graphics

- Future Trends in Flexo-Graphics: Innovations Shaping the Industry

- FAQS

- Conclusion

- Related Posts

In today’s super competitive market, making your brand stand out is more important than ever. One pretty exciting way to boost your brand's identity is by using Flexo-Graphics techniques—that's a game-changer. I recently came across a report from Smithers Pira, and it’s pretty wild: they’re saying the world’s demand for flexible packaging will hit around $300 billion by 2025. That really highlights how crucial it is to adopt the latest printing tech. Since founding in 2007, Shanghai Eureka Machinery has been leading the charge in this space, offering top-notch printing and packaging equipment to clients all over the globe—spanning 88 countries across Europe, Asia, and Africa. When you leverage Flexo-Graphics, you get those vibrant prints and high-quality results that really make your brand pop and leave a lasting impression with your audience. In this post, I want to dive into how these techniques can totally transform your branding efforts and help set your business up for long-term success.

Understanding Flexo-Graphics: An Overview of Techniques and Applications

Flexo-graphics is this pretty cool printing tech that’s been catching on more and more because of how versatile and efficient it is for all kinds of jobs. Basically, it uses these flexible relief plates that let you get sharp, high-quality images on just about any material—whether it’s packaging, labels, or even some of the more niche printing projects out there. Because of its unique features, a lot of brands prefer it when they want their packaging and branding to really stand out. As industries keep changing and growing, it’s super important for companies to get a handle on the different flexo-graphics techniques. That way, they can step up their game and make their products pop on the shelves.

Plus, there’s been some pretty exciting advancements lately. For example, AI-powered flexographic presses are a game-changer—they let printers work more precisely and automatically, and they can adapt on the fly to meet different demands. And then there’s the research into flexoelectric effects in various materials, which could mean some pretty energy-efficient printing solutions down the line. With big events like Labelexpo Mexico 2025 coming up, staying in the loop about these trends and tech could really help brands boost their visibility and get ahead in the market.

How to Transform Your Branding with Flexo-Graphics Techniques - Understanding Flexo-Graphics: An Overview of Techniques and Applications

| Technique | Description | Applications | Advantages |

|---|---|---|---|

| Digital Flexo | A modern approach combining digital technologies with flexographic printing. | Labels, packaging, and specialty printing. | Faster production times and high-quality prints. |

| Inline Flexography | Printing process integrated into the production line for efficiency. | Flexible packaging and corrugated boxes. | Reduction in steps and increased speed. |

| Pre-Press Techniques | Process of preparing the design for printing through various methods. | All types of flexographic prints. | Improved color registration and print quality. |

| Water-Based Inks | Inks made using water as a solvent, reducing environmental impact. | Food packaging and eco-friendly products. | Safer for the environment and faster drying times. |

| Rotogravure Techniques | Engraved cylinder printing for high-quality images. | High-volume packaging and publishing. | Exceptional quality and detail in prints. |

The Role of Color in Flexo-Graphics: Enhancing Brand Identity

When it comes to branding, colors really hold the power to create a memorable identity that sticks with consumers. Thanks to flexo-graphics techniques, brands now have a pretty cool way to boost color vibrancy and precision in their packaging and printing. Using these advanced methods, you can achieve eye-catching visuals that don’t just grab attention but also clearly communicate your brand’s values. Plus, the process allows for a wide range of colors to be applied smoothly, making your products more appealing and helping your brand stand out in a crowded market.

At SHANGHAI EUREKA MACHINERY IMP. & EXP. CO., LTD, we’re all about helping businesses unlock the full potential of flexo-graphics with our top-notch printing and packaging equipment. We got started way back in 2007, and since then, we’ve built a solid reputation as a leading producer and exporter — we're proud to be recognized in 88 countries for our quality and innovation. Our cutting-edge machinery makes it easy to turn your branding ideas into reality, delivering rich colors and crisp print quality that help your products shine on store shelves and really connect with your audience. So, why not embrace the magic of color with flexo-graphics and take your brand to the next level?"

Surface Textures and Effects: Making Your Branding Stand Out

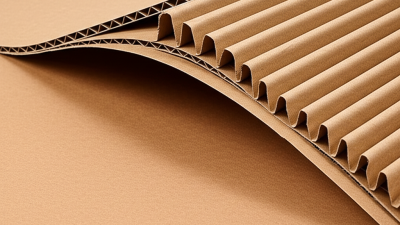

When it comes to branding, first impressions really count, and the textures on your packaging can make a huge difference in helping your brand stand out. Flexo-graphics techniques are a great way to add unique textures and effects that actually make people want to touch and feel what you're offering. Picture this: a product package that doesn’t just look good but also invites you to run your fingers over it. Whether it’s a subtle raised print or a soft-touch surface, adding these tactile details turns a boring, standard design into something memorable and engaging.

Plus, the awesome part is you can customize these textures to match your brand’s vibe. Want something rustic and earthy that gives off nostalgic feels? Or maybe a sleek, modern finish that screams innovation? The possibilities are pretty much endless. Playing around with finishes like gloss, matte, or even metallic can really make your packaging pop and catch people’s eyes, encouraging them to pick it up and take a closer look. When you combine interesting textures with eye-catching design, it not only reinforces what your brand is all about but also makes your packaging stand out from the crowd in a really cool way.

Cost Efficiency of Flexo-Graphics Compared to Other Print Methods

Lately, it’s pretty clear that flexo-graphics is really holding its own, especially when you compare it to other printing methods. As technology keeps progressing, we’re seeing more and more that flexo still dominates, especially in the label world. It's surprising how much of the label market it still captures. Thanks to automation and better processes, flexo can now go head-to-head with digital printing—especially when it’s about short runs. The automation side of things has really ramped up efficiency, cutting down on labor costs and waste, so companies can react faster to changing market trends without breaking the bank.

And, with digital packaging growing like crazy, flexo printers are not just standing still—they're adapting. A lot of industry reports are pointing out that digital printing is getting faster and better in quality, which means it’s starting to take some market share from traditional methods. To stay competitive, many flexo shops are bringing in hybrid systems that combine the best of both worlds—printing speed, quality, and cost efficiency. Plus, with improved ink management systems and newer platemaking tech, flexo remains a smart choice for brands wanting to keep their costs low but still stand out on the shelves. It’s all about blending tradition with innovation to stay ahead of the game.

Real-Life Case Studies: Successful Branding through Flexo-Graphics

You know, over the past few years, the printing and packaging world has really been changing—big time. There's been a noticeable shift towards more advanced flexo-graphics techniques, and honestly, it’s making a huge difference when it comes to catching people’s eyes and building brand recognition. I read in a report from Smithers Pira that the global flexographic printing market is set to top $250 billion by 2027. That really shows how important this method is becoming for brands trying to stand out. And it's not just numbers—real companies using flexo-graphics are seeing results. For example, a popular beverage brand switched up its packaging using flexo-graphic printing, and guess what? They saw a 30% jump in sales. The new, vibrant colors and sleek designs really clicked with consumers.

Right now, quite a few companies are leading the charge in this area, and one of the big names is SHANGHAI EUREKA MACHINERY IMP. & EXP. CO., LTD. They've been in the game since 2007 and have built quite a reputation—shipping their tech all over Europe, Asia, and Africa. What’s cool is their focus on blending innovative flexo-graphics tech into their machinery, making it easier for brands to get the wow factor and really tell their story visually. By leveraging these cutting-edge techniques, brands aren't just staying competitive—they’re reaching more people and transforming how they connect with their audiences. It’s pretty exciting stuff, honestly.

Future Trends in Flexo-Graphics: Innovations Shaping the Industry

Flexo-graphics is evolving at a pretty fast pace these days, thanks to new tech and what consumers are looking for. One of the coolest trends I’ve been noticing is how brands are blending digital tech with traditional flexo printing. It’s like the best of both worlds — they get better color control, less waste, and faster turnaround times. You see more companies going for these hybrid setups, mixing digital and analog methods to produce top-notch prints that really speak to a diverse customer base.

And, you know, there’s also a real push towards sustainability in the industry. People are more mindful about the environment, so brands are on the lookout for eco-friendly inks and materials that don’t leave a heavy footprint. Things like water-based inks and biodegradable substrates are becoming more common, helping the industry move toward greener practices without sacrificing quality. It’s pretty exciting because this focus on innovation isn’t just about better branding — it’s about leading the way to more responsible and sustainable solutions overall.

FAQS

: Flexo-graphics is an innovative printing technology that uses flexible relief plates to produce high-quality images on various substrates, making it popular in packaging, labels, and specialized printing sectors.

Flexo-graphics is recognized for its cost efficiency, especially in the label sector, where it can compete with digital printing for short-run productions due to advancements in automation and improved processes that reduce labor costs and waste.

Recent advancements include the integration of AI-powered flexographic presses for automated printing processes and the exploration of flexoelectric effects in materials for energy-efficient production.

Automation enhances efficiency, reduces labor costs, and diminishes waste, enabling companies to respond better to rapidly changing market demands.

Future trends include the integration of digital technologies with traditional flexographic processes for improved color management and the focus on sustainable practices, such as using eco-friendly inks and biodegradable materials.

Companies in the flexo-graphics industry are adopting water-based inks and biodegradable materials to minimize their ecological footprint and meet growing consumer expectations for environmentally responsible solutions.

Hybrid printing models combine digital and analog methods, allowing brands to create high-quality impressions while benefiting from the strengths of both printing techniques.

Flexo-graphics techniques are evolving by incorporating digital technologies for faster turnaround times and better precision, as well as adapting to the increasing speed and quality of digital printing technologies.

Events like Labelexpo Mexico 2025 provide opportunities for companies to stay informed about the latest trends and advancements in flexo-graphics, allowing them to leverage these innovations for branding and product visibility.

Understanding flexo-graphics techniques and advancements is essential for brands looking to enhance their visual identity and market presence in a competitive landscape.

Conclusion

In the fast-changing world of branding and packaging, Flexo-Graphics techniques have really become a go-to tool for businesses looking to boost their identity and stand out in the market. In this post, I want to give you a good rundown of what Flexo-Graphics is all about—covering its many different uses and showing how important color is when it comes to making a brand memorable. Plus, we’ll talk about how surface textures and cool effects can really help a brand catch the eye and set itself apart from the competition.

And honestly, one of the biggest perks of Flexo-Graphics is how budget-friendly it is—especially when you compare it to other printing options. This makes it a popular choice for lots of companies trying to get the most bang for their buck. To back this up, I’ll share some real-world examples of brands that have successfully used Flexo-Graphics to level up their branding. We’ll also peek into what's coming next—future trends and innovations that could really change the game.

As a company that leads the way in printing and packaging machinery, SHANGHAI EUREKA MACHINERY IMP. & EXP. CO., LTD is all about helping brands succeed with the latest Flexo-Graphics tech. Our goal? To give businesses the tools they need to transform their branding and make a real impact.

Related Posts

-

What is an Automatic Cardboard Box Making Machine and How Does It Revolutionize Packaging?

-

Addressing Common Issues Faced by Laminator Users in Spanish Markets: A Data-Driven Perspective

-

Exploring Options for the Viena Seja Gofrētā Kartona Mašīna in Packaging Solutions

-

Cardboard Laminators: A Comprehensive Comparison of Top Models for Global Buyers

-

Essential Checklist for Choosing the Right Flat Bed Cutting Machine for Your Business

Blog Tags: