Top Digital Cutter Machines to Boost Your Printing Business Efficiency

Table of Contents

- Overview of Digital Cutter Machines in the Printing Industry

- Key Features to Consider When Choosing a Digital Cutter Machine

- Comparison of Popular Digital Cutter Brands and Models

- Benefits of Integrating Digital Cutters into Printing Workflows

- Maximizing Efficiency: Best Practices for Using Digital Cutters

- Maintenance Tips for Longevity and Optimal Performance of Cutters

- Future Trends in Digital Cutting Technology for Printing Businesses

- FAQS

- Conclusion

- Related Posts

You know, in today’s fast-changing world of printing, it’s become pretty clear that using the latest tech is a game-changer for businesses that want to stay ahead. One tool that’s really making waves is the Digital Cutter Machine. Not only does it make workflows smoother and faster, but it also helps boost the quality of the output. I came across a recent report from Smithers Pira that said the digital cutting market is expected to grow by over 15% each year — mainly because more folks are asking for customized and short-run print jobs, which is pretty interesting.

Digital Cutter Machines give print shops the kind of flexibility and precision they need to handle all sorts of jobs — whether it’s super detailed designs or big-format projects. Companies like Mimaki, Kongsberg, and Zünd are really leading the charge in this space, introducing features like automatic feeding and seamless software integration. Honestly, with so much competition out there, investing in a good-quality Digital Cutter Machine could be the thing that sets you apart and helps your business thrive in this digital-driven world.

Overview of Digital Cutter Machines in the Printing Industry

Digital cutter machines have become essential tools in the printing industry, significantly enhancing productivity and precision. According to a recent report by Smithers Pira, the global market for digital cutting machines is expected to reach $1.2 billion by 2025, driven by increasing demand for custom and short-run printing. This technology allows businesses to streamline operations and cut lead times, offering a competitive edge in an ever-evolving market.

The versatility of digital cutters makes them ideal for various applications, from packaging to signage. A survey conducted by the Printing Industries of America revealed that nearly 60% of print businesses have adopted digital cutting technologies within the last three years. This shift indicates a growing recognition of the need for efficient production methods that can accommodate complex designs and materials. Furthermore, digital cutting machines minimize waste and reduce setup times, leading to higher profit margins and sustainability in print operations. The adoption of these machines marks a significant evolution in the printing landscape, enabling businesses to harness innovative solutions to meet customer demands.

Key Features to Consider When Choosing a Digital Cutter Machine

When selecting a digital cutter machine, various key features play a crucial role in enhancing the efficiency of your printing business. One important factor to consider is precision and cutting accuracy. According to industry reports, machines with enhanced cutting capabilities can achieve precision rates within ±0.1mm. This level of detail not only improves the quality of final products but also minimizes waste material, making operations more cost-effective.

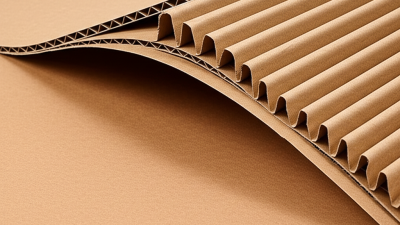

Another critical feature is compatibility with various materials. High-quality digital cutters can handle an array of substrates, from paper and cardboard to vinyl and textiles, expanding the range of potential applications. A recent market analysis revealed that businesses utilizing versatile cutting machines reported a 30% increase in project turnaround time. This adaptability can significantly boost productivity, allowing firms to meet diverse client needs more efficiently.

Additionally, automation and software integration are essential considerations. Modern digital cutter machines often come equipped with user-friendly software that streamlines design to production workflows. Research indicates that organizations implementing advanced automation in their cutting processes have experienced a reduction in labor costs by up to 25%. By investing in a machine that incorporates these essential features, companies can not only enhance their operational efficiency but also stay competitive in a rapidly evolving market.

Comparison of Popular Digital Cutter Brands and Models

When evaluating digital cutter machines, several brands and models stand out for their performance and reliability in enhancing printing business efficiency. The Graphtec CE7000 series, for instance, is known for its precision cutting capabilities and user-friendly software integration, making it an excellent choice for businesses looking to streamline their workflow. With options for various media types and thicknesses, the CE7000 is particularly favored for its versatility in handling different projects.

Another strong contender is the Roland GS series, which offers advanced cutting technology and the ability to print and cut in one go. This dual functionality is a key advantage for printing businesses that aim to save time and resources. The GS series is also equipped with features such as contour cutting and efficient registration mark detection, ensuring high-quality results for intricate designs. Additionally, the Mimaki CG Series is recognized for its robust build and ability to handle heavy-duty applications, making it suitable for larger print shops requiring durable equipment.

In summary, selecting the right digital cutter can significantly impact a printing business's efficiency. The Graphtec CE7000, Roland GS, and Mimaki CG Series each bring unique advantages to the table, enabling businesses to achieve better workflow and improve overall productivity in their operations.

Efficiency Comparison of Digital Cutter Machines

Benefits of Integrating Digital Cutters into Printing Workflows

Integrating digital cutters into printing workflows can significantly enhance efficiency and accuracy, revolutionizing the way printing businesses operate. According to a recent report by Smithers Pira, the digital print market is projected to grow at a compound annual growth rate (CAGR) of 8.7% from 2021 to 2026. The introduction of advanced digital cutter machines allows for precise cutting, efficient material usage, and the ability to handle diverse applications, from intricate designs to large format prints. This technology not only reduces waste but also improves turnaround times, enabling businesses to meet the increasing demands of their customers.

Furthermore, adopting digital cutting technology aligns with the latest printing industry trends emphasizing automation and customization. A study from Technavio indicated that the global digital printing market is expected to reach $182 billion by 2027, driven by the need for personalized products and on-demand printing solutions. As businesses pivot toward these trends, integrating digital cutters can streamline processes, reduce labor costs, and enhance the overall customer experience by enabling faster delivery and higher quality products. Adopting these innovations is essential for staying competitive in a rapidly evolving market.

Top Digital Cutter Machines to Boost Your Printing Business Efficiency - Benefits of Integrating Digital Cutters into Printing Workflows

| Machine Model | Cutting Area (mm) | Max Material Thickness (mm) | Cutting Speed (m/min) | Primary Benefits |

|---|---|---|---|---|

| Model A | 1300 x 2500 | 10 | 2.5 | High precision, Versatile material handling |

| Model B | 1600 x 3000 | 8 | 3.0 | Fast setup times, High throughput |

| Model C | 900 x 1800 | 5 | 1.5 | Compact size, Easy to integrate |

| Model D | 2000 x 4000 | 12 | 4.0 | Supports multiple tools, High durability |

Maximizing Efficiency: Best Practices for Using Digital Cutters

In today’s competitive printing industry, maximizing efficiency through the use of digital cutter machines is essential for success. Digital cutting technology not only speeds up the production process but also enhances accuracy, reducing waste and operational costs. According to industry reports, businesses that integrate digital cutters can see a productivity increase of up to 30%, which significantly impacts their bottom line.

To get the most out of your digital cutter, here are some best practices to implement. First, invest in training for your staff to ensure they are familiar with the machine's capabilities and features. Understanding the software that accompanies digital cutters can lead to better design and implementation processes. Secondly, regularly maintain your equipment. Scheduled downtime for servicing can prevent more costly repairs in the future and keep production running smoothly. Lastly, optimize workflow by integrating your cutter with other digital processes to streamline operations and maximize throughput.

By following these tips, printing businesses can not only boost their operational efficiency but also enhance the quality of their outputs, leading to increased customer satisfaction and loyalty. The landscape is evolving, and those who leverage digital technology effectively will undoubtedly capture a larger market share in the industry.

Maintenance Tips for Longevity and Optimal Performance of Cutters

When it comes to maximizing the performance of digital cutter machines in your printing business,

regular maintenance is key. A well-maintained cutter not only ensures precision and efficiency but also

extends its lifespan, which can lead to significant cost savings over time.

To maintain optimal performance, one effective tip is to regularly clean the

blades and cutting areas. This helps prevent the accumulation of dust and debris that can impact cutting accuracy.

Additionally, it's essential to check and align the cutter settings periodically to ensure they're

calibrated correctly for the materials you're working with.

Another important aspect of maintenance is inspecting the electrical components and

connections. Keep an eye out for any wear and tear that may lead to malfunctions or reduced efficiency. By dedicating

time to routine checks and maintenance, you can keep your digital cutter running

smoothly and avoid costly downtime in your printing operation.

Future Trends in Digital Cutting Technology for Printing Businesses

As we look toward the future of digital cutting technology in the printing industry, several trends are emerging that promise to enhance efficiency and innovation. By 2024, the global printed circuit board market is projected to reach $71.57 billion, with expectations to grow further in the years to come. This growth is indicative of the increasing reliance on advanced digital solutions, which include cutting technologies that streamline production processes and reduce material waste.

The integration of smart technologies within cutting machines is revolutionizing how printing businesses operate. Automation and artificial intelligence are expected to play pivotal roles in optimizing workflows and enhancing precision in cutting operations. Companies that invest in the latest digital cutter machines will not only improve operational efficiency but also respond adeptly to the evolving demands of the market. As we move toward 2025, the emphasis on sustainability and efficiency will continue to drive innovations in digital cutting, ensuring that businesses remain competitive in a rapidly changing landscape.

FAQS

: Digital cutter machines are used for various applications in the printing industry, including packaging and signage, enhancing productivity and precision while accommodating complex designs and materials.

The demand is increasing due to the rise in custom and short-run printing, as businesses seek to streamline operations, reduce lead times, and gain a competitive edge in the market.

Important features include precision and cutting accuracy, compatibility with various materials, and automation and software integration, which enhance operational efficiency and reduce waste.

Many digital cutter machines can achieve precision rates within ±0.1mm, improving product quality and minimizing waste material.

Businesses that utilize digital cutters can experience productivity increases of up to 30%, allowing them to meet client needs more efficiently.

Investing in staff training helps ensure familiarity with the machine's features and software, leading to better design and implementation processes.

Regular maintenance helps prevent costly repairs and keeps production running smoothly, contributing to overall operational efficiency.

Integrating digital cutters with other digital processes can streamline operations and maximize throughput, enhancing overall efficiency.

By minimizing waste and reducing setup times, digital cutter machines contribute to higher profit margins and sustainability in print operations.

The global market for digital cutting machines is expected to reach $1.2 billion by 2025, indicating continued growth driven by demand for efficient and versatile printing solutions.

Conclusion

The article "Top Digital Cutter Machines to Boost Your Printing Business Efficiency" provides a comprehensive overview of digital cutter machines and their significance in the printing industry. It explores key features to consider when selecting a digital cutter machine, compares popular brands and models, and highlights the benefits of integrating these cutting-edge tools into printing workflows. Best practices for maximizing efficiency and essential maintenance tips for ensuring longevity and optimal performance are also discussed.

As a leader in the printing and packaging machinery sector, SHANGHAI EUREKA MACHINERY IMP. & EXP. CO., LTD emphasizes the critical role of digital cutter machines in enhancing business efficiency. The article concludes by examining future trends in digital cutting technology, providing insights that align with Eureka Machinery's commitment to innovation and excellence in the industry across Europe, Asia, and Africa.

Related Posts

-

Exploring Options for the Viena Seja Gofrētā Kartona Mašīna in Packaging Solutions

-

10 Essential Tips for Using Die Cutter Paper Like a Pro

-

Exploring the Innovative Applications of Fluting Machines in Modern Manufacturing

-

Cardboard Laminators: A Comprehensive Comparison of Top Models for Global Buyers

-

Exploring Market Trends in Die Cutting Machine For Paper at 2025 China Import and Export Fair

-

Unlocking the Secrets of Offset Press Machines for Superior Printing Quality

Blog Tags: