Revolutionizing Precision: The Future of Automatic Die Cutters in Modern Manufacturing

Table of Contents

- The Evolution of Die Cutting Technology: A Look Back

- Understanding the Mechanisms: How Automatic Die Cutters Work

- Key Advantages of Implementing Automatic Die Cutters in Manufacturing

- Innovations in Materials and Processes Benefiting Die Cutting

- Future Trends: Smart Automation and Industry 4.0 in Die Cutting

- Challenges Facing the Adoption of Automatic Die Cutters in Modern Manufacturing

- Innovative Cutting Solutions: Exploring the Features and Benefits of the GUOWANG C80Q Automatic Die-Cutter with Stripping

- FAQS

- Conclusion

- Related Posts

You know, advances in manufacturing technology are really opening up new possibilities across different industries—especially in printing and packaging. If you’ve seen recent industry reports, you’ll notice that the global market for automatic die cutters is expected to hit around $2.5 billion by 2025, mainly because companies are craving more precision and efficiency in their production lines. Take SHANGHAI EUREKA MACHINERY IMP. & EXP. CO., LTD, for example. Founded back in 2007, they’re really leading the charge in this space, earning a reputation as a top manufacturer and exporter of printing and packaging machinery. They’ve built a pretty impressive network that spans 88 countries across Europe, Asia, and Africa. Eureka Machinery is all about staying on the cutting edge—like integrating super advanced equipment such as the Automatic Die Cutter. This isn’t just about making things look good; it actually boosts product quality and accuracy while making the whole process more efficient. Honestly, they’re setting some pretty high standards in today’s manufacturing world.

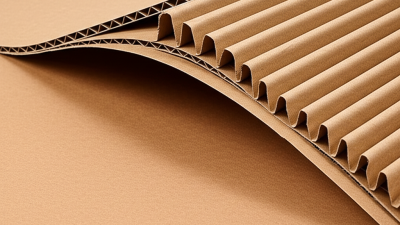

The Evolution of Die Cutting Technology: A Look Back

You know, the die-cutting world has gone through some pretty incredible changes over the years. It's really bumped up how precise and efficient manufacturing can be. If you look back, it all started with manual die-cutting—big, clunky, and honestly, pretty error-prone. Then came the mid-1900s, when mechanical die-cutters hit the scene. That was a game-changer, making cuts more accurate and speeding things up quite a bit. Industry folks estimate that by 2025, the global die-cutting market will hit around $6 billion, thanks mainly to smarter automation and digital tech making everything smoother.

Lately, the biggest shift has been toward automatic die-cutters. These machines, powered by CNC tech, let manufacturers craft super detailed designs without wasting much material. The National Institute of Standards and Technology says that using automated systems can cut down production times by up to 30%. Plus, they’re way more accurate, which means less scrap and better results overall. As more companies jump on board with these advanced tools, it’s pretty exciting to think about where die-cutting technology is headed—more precision, faster production, and the ability to meet all sorts of industry demands with ease.

Understanding the Mechanisms: How Automatic Die Cutters Work

Automatic die cutters are truly a big step forward in today's manufacturing world, especially when precision and efficiency are such big deals. But if you really understand how these machines work, you'll see there's quite a bit of complexity behind their operation. Generally, these cutters blend mechanical parts with digital controls—kind of like a high-tech combo—to make sure the cuts are spot-on. They can be set up to work with different materials and tight tolerances because of some smart sensors and control systems that keep a close eye on everything happening during the cutting process.

On the automation front, there’s this whole trend of developing robotic systems—like the ones used for pruning apple trees—that show how we're moving toward smarter manufacturing. These robots often have new, innovative cutting mechanisms that help keep things running smoothly and cut down on labor costs. Similarly, automatic die cutters use cutting-edge tech to handle large production runs, boosting both speed and accuracy—crucial factors in packaging, printing, and other industries.

If you’re thinking about upgrading your equipment, a good rule of thumb is to check what kinds of materials you’re working with and how much you're planning to produce. It’s smart to pick a model that can mesh well with your current workflow so you get the most out of it. And don’t forget—regular maintenance is key. Keeping the machines in good shape ensures they serve you well for the long haul and helps keep downtime to a minimum.

Key Advantages of Implementing Automatic Die Cutters in Manufacturing

You know, these days, automatic die cutters are really changing the game in manufacturing. They’re making precision cutting way more efficient, and honestly, they’re saving a lot on labor costs too. By automating the whole die-cutting process, companies can smooth out their workflows, cut down on human mistakes, and crank out more products faster — all without having to hire a whole bunch of extra workers. Pretty cool, right?

And here’s the best part: these machines are super precise and consistent. They use fancy technology and smart software to make accurate cuts every single time, even across huge batches. That not only means the products turn out looking pretty perfect, but it also helps cut down on wasted materials, which is good for the environment as well. Plus, since they can easily switch up designs and materials on the fly, businesses can stay flexible and keep up with a market that’s always changing. It’s like having a tool that helps them adapt quickly and meet all sorts of customer needs—pretty amazing stuff.

Innovations in Materials and Processes Benefiting Die Cutting

Hey, have you noticed how the die cutting industry is really going through some big changes lately?

It’s like, thanks to all these new materials and better processes, things are becoming more advanced. I read that,

according to TechSci Research, the global market for die cutting machines is expected to hit around $3.3 billion by 2026,

and it’s growing at an average of over 5% since 2021. A lot of this growth is because manufacturers are now using

super high-performance polymers and new composite materials, which not only give cleaner cuts but also last longer. Plus, they’re opting for lighter yet tough materials,

which opens up all sorts of possibilities in industries like automotive, electronics, and packaging.

On top of that, the technology behind die cutting is evolving fast. Automated systems and smart die cutters

with AI are really changing the game — making the whole process smoother, cutting down on waste, and boosting efficiency. For example, a report from

Market Research Future mentions that these smart cutters can slash production times by nearly

30%. That means manufacturers can quickly adapt to what’s in demand. All these innovations in materials and tech aren’t just about making better products;

they’re also helping the industry be more sustainable, which is pretty exciting when you think about it.

The future of die cutting looks pretty promising, don’t you think?

Future Trends: Smart Automation and Industry 4.0 in Die Cutting

You know, the way smart automation and Industry 4.0 tech are coming together is really going to shake up how we do die cutting in today's manufacturing world. Thanks to IoT devices, manufacturers can now hook up their die-cutting machines to the internet, which means they can monitor everything in real-time and gather data as they go. It’s a game-changer because it helps catch maintenance issues before they become big problems, cutting down on downtime and boosting overall efficiency. Plus, with machine learning, companies can fine-tune their cutting patterns, cut down on waste, and hit much higher precision — all leading to better quality products.

As everyone’s craving more customization and flexibility, these automatic die cutters featuring cool robotics and AI are quickly becoming essential. They’re super adaptable, so businesses can tweak their production on the fly and stay agile when market demands shift. On top of that, using smart tech allows manufacturers to dig into operational data, which means making smarter improvements all the time — both in the process and the final product. This blend of automation and Industry 4.0 isn’t just making die-cutting smoother; it's also pushing us toward more sustainable manufacturing, helping to lessen environmental impact and keeping companies competitive in a fast-changing industry.

Revolutionizing Precision: The Future of Automatic Die Cutters in Modern Manufacturing

| Feature | Current Trends | Future Predictions |

|---|---|---|

| Smart Automation | Increased integration of AI for predictive maintenance | Full automation with real-time adjustments to operations |

| Material Efficiency | Use of eco-friendly and recyclable materials | Innovations in material sciences leading to reduced waste |

| Customization | Increased demand for bespoke manufacturing solutions | Hyper-personalization with on-demand die cutting services |

| IoT Integration | Implementation of IoT for monitoring machine performance | Fully interconnected systems communicating across platforms |

| Speed & Efficiency | Faster setups and improved cycle times | Blazing speeds with minimal downtime |

Challenges Facing the Adoption of Automatic Die Cutters in Modern Manufacturing

Switching over to automatic die cutters in today's manufacturing world isn’t exactly a walk in the park. For one thing, these machines tend to cost a pretty penny, which can be a real hurdle—especially for smaller factories that might not have the budget for such a big upfront investment. Honestly, that can make folks pretty hesitant to jump ship from their old-school methods, even if newer tech could give them a leg up in a competitive, ever-changing market.

Then there’s the whole challenge of getting these new machines to fit into what they've already got going on. It’s not just plug-and-play, you know? Staff often need training, processes must be tweaked, and all that takes time—and during that time, production can slow down a bit. Plus, these high-tech machines need reliable support and maintenance to keep running smoothly. For many businesses, that added complexity can feel like a big obstacle, making the whole switch seem daunting at first.

Innovative Cutting Solutions: Exploring the Features and Benefits of the GUOWANG C80Q Automatic Die-Cutter with Stripping

The GUOWANG C80Q Automatic Die-Cutter with Stripping brings a new level of innovation to the printing and packaging industry, particularly through its advanced cutting solutions. This machine features a high-quality feeder designed with four suckers for lifting paper and another four for forwarding, ensuring stable and rapid feeding. Importantly, the adjustable height and angle of these suckers keep the sheets perfectly straight, which is crucial in maintaining precision throughout the die-cutting process.

In addition to its efficient feeding mechanism, the GUOWANG C80Q is equipped with a mechanical double-sheet detector, a sheet-retarding device, and an adjustable air blower. These features collectively ensure that sheets are transferred steadily and precisely to the belt table, minimizing the risk of errors during operation. Such advancements are not just beneficial but essential; according to a recent industry report, improper feeding can lead to a 25% decrease in production efficiency, highlighting the importance of reliable equipment in maintaining a smooth workflow.

Powered by a German Becker vacuum pump, the GUOWANG C80Q emphasizes durability and performance. The use of high-quality components ensures a low failure rate, allowing for prolonged operational uptime—an essential factor in today’s fast-paced printing environments. Embracing such cutting-edge technology can significantly enhance production capabilities, ultimately driving growth in a competitive market.

FAQS

: Die cutting technology is a manufacturing process that involves cutting materials into specific shapes using specialized machines known as die cutters.

Die cutting technology has evolved from manual techniques, which were labor-intensive, to mechanical die-cutters, and most recently to automatic die cutters that utilize computer numerical control (CNC) technology, improving precision and efficiency.

The global die-cutting market is projected to reach $6 billion by 2025, driven by advancements in automation and digital technology.

Automatic die cutters offer benefits such as reduced production time by up to 30%, improved accuracy, and better material usage compared to traditional methods.

Manufacturers face challenges such as significant financial investment, integration complexity into existing production lines, retraining staff, and the need for reliable technical support and maintenance.

The significant upfront costs associated with automatic die cutters may deter many manufacturers, particularly smaller operations, from upgrading from traditional methods, affecting their competitiveness.

While automatic die cutting can enhance production efficiency and precision in the long run, there may be initial inefficiencies due to the learning curve associated with integrating new technology.

Retraining staff is necessary to ensure they can effectively operate the new automatic die cutters and adapt to changes in manufacturing processes, which is critical for maintaining productivity.

Reliable technical support is essential for maintaining optimal operation of automatic die cutters, helping manufacturers address any complications that arise during the transition to new technology.

The future of die cutting technology looks promising as manufacturers continue to adopt advanced techniques that enhance precision and meet the growing demands of various industries.

Conclusion

So, I was reading this article called "Revolutionizing Precision: The Future of Automatic Die Cutters in Modern Manufacturing," and honestly, it was pretty eye-opening. It takes you through how die cutting tech has evolved over the years and shows just how much automatic die cutters have changed the manufacturing game. The article explains the complex tech inside these machines, but what really stands out are their main perks—like how much faster and more precise they’ve become. Plus, it dives into some cool innovations in materials and processes that boost die cutting even more. Oh, and it also hints at where things are headed—think smarter automation and Industry 4.0 stuff—making everything even more seamless. Sure, switching over to automatic die cutters isn’t all sunshine and rainbows—there are some hurdles—but honestly, the pros seem to outweigh the cons by a mile. They’re definitely becoming a must-have in today’s manufacturing world.

And speaking of industry leaders, SHANGHAI EUREKA MACHINERY IMP. & EXP. CO., LTD gets how big of a deal these advances are. With their strong global presence, Eureka Machinery is all in on delivering the latest and greatest solutions—making sure their clients stay ahead with cutting-edge tools like these automatic die cutters and more.

Related Posts

-

Exploring Market Trends in Die Cutting Machine For Paper at 2025 China Import and Export Fair

-

What Makes a Cut Die Cutter Essential for Your Business

-

Revolutionizing Precision: The Science Behind Automatic Die Cutters and Their Applications

-

Exploring Options for the Viena Seja Gofrētā Kartona Mašīna in Packaging Solutions

-

How to Transform Your Branding with Flexo-Graphics Techniques

-

7 Reasons Why the Ultimate Bag Making Machine is a Game Changer for Your Business

Blog Tags: