Revolutionizing Packaging: The Ultimate Guide to Choosing the Right Automatic Folder Gluer

Table of Contents

- Understanding the Basics of Automatic Folder Gluers: Key Features to Consider

- Evaluating Your Production Needs: Choosing the Right Size and Speed

- Material Compatibility: Matching Folder Gluers with Your Packaging Materials

- Automation vs. Manual Processes: Weighing the Pros and Cons

- Essential Maintenance Tips for Optimal Performance of Your Gluer

- Budgeting for Efficiency: Cost Considerations When Purchasing a Folder Gluer

- Enhancing Print Quality and Efficiency: Insights from Market Reports on the HIS-1650W High Speed UV Spot and Overall Coating Machine

- FAQS

- Conclusion

- Related Posts

These days, the packaging industry moves pretty quick, right? And the machinery you choose really makes a big difference in how smoothly things run and how good your products turn out. I came across a recent report by Smithers Pira that says the global market for packaging equipment is expected to hit around $50 billion by 2025. And interestingly, automatic folder gluers are kind of taking center stage in this growth—they’re becoming a key part of the scene. These machines do a lot to speed up the packaging process, and they’re pretty precise when it comes to sticking everything together, which is super important to keep the products intact.

Now, here’s a company that’s been leading the charge—SHANGHAI EUREKA MACHINERY IMP. & EXP. CO., LTD. They’ve been around since 2007 and are known as a top player in printing and packaging machinery. With a presence in 88 countries across Europe, Asia, and Africa, Eureka Machinery really knows their stuff and is all about providing quality solutions that adapt to the changing needs of the market. Picking the right automatic folder gluer isn’t just a small decision—it can really boost your production speed and quality. So, if you’re looking to up your packaging game, this guide should definitely help you out.

Understanding the Basics of Automatic Folder Gluers: Key Features to Consider

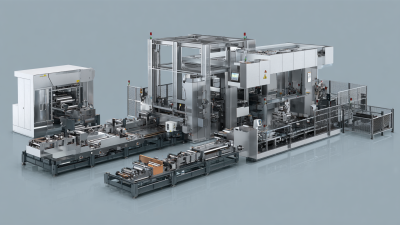

So, when you're picking out an automatic folder gluer, it really helps to know what features actually make it efficient and perform well. These machines are built to make your packaging process smoother by providing precise folding and gluing— which can really boost your productivity. Some of the main things to look at are how fast the machine runs, how versatile it is, and how user-friendly it feels. A faster machine can easily handle different types of materials and sizes, cutting down your turnaround time. On the other hand, versatility means it can handle various packaging designs without a fuss.

Here at SHANGHAI EUREKA MACHINERY IMP. & EXP. CO., LTD, we're pretty proud of our cutting-edge automatic folder gluers—they're made to keep up with the ever-changing demands of the packaging world. We started back in 2007, and over the years, Eureka Machinery has built a solid reputation as a top-notch manufacturer and exporter of printing and packaging equipment. We’re active in 88 countries across Europe, Asia, and Africa, and our focus on quality and innovation means you get reliable, efficient packaging solutions—plain and simple.

Evaluating Your Production Needs: Choosing the Right Size and Speed

So, when you're trying to pick out the right automatic folder gluer for your packaging biz, it's really important to first get a clear picture of what your production needs are. I mean, according to a report by Smithers Pira, the global packaging market's expected to hit a whopping $1 trillion by 2024—that just shows how much everyone's craving efficient packaging solutions these days. One of the biggest things to think about is the size of the gluer. If you're packing a ton of corrugated boxes or folding cartons, going for a bigger machine that can handle large runs will seriously boost your output and help avoid those annoying bottlenecks that slow everything down.

Speed is also a big deal. Some studies say that typical automatic folder gluers run anywhere from 9,000 up to 25,000 square feet an hour. So, picking a model with a higher speed could really give your productivity a nice boost, especially if you're in a fast-moving operation. But hey, don’t just go for the fastest machine out there—make sure it matches your actual output needs so you’re not wasting resources. The trick is to find that sweet spot between size and speed, so you're not only meeting today’s demands but also staying flexible enough for growth down the line. And if you peek at what Allied Market Research is saying, it looks like this sector’s gonna keep on growing, which is pretty exciting for anyone in the game.

Material Compatibility: Matching Folder Gluers with Your Packaging Materials

Picking the right automatic folder gluer can really make a difference when it comes to boosting your packaging workflow. But honestly, it’s super important to find one that works well with your materials. I came across a recent report by Smithers Pira that says the global market for folding carton packaging is expected to hit a whopping $270 billion by 2027 — so, yeah, there's a big need for machinery that can handle all kinds of materials out there. When you're shopping around for a folder gluer, think about whether it can work with different substrates like coated papers, uncoated papers, or even plastics. Each material kind of requires its own type of adhesive and gluing method to make sure everything stays sturdy and looks good.

And let’s not forget, the performance and lifespan of your entire packaging line really depend on whether your folder gluer can keep up with your material choices. For example, if you’re working with heavier substrates, you’ll want a machine that has robust feeding and glue systems—otherwise, jams and slowdowns can become a real headache. According to a study by the Packaging Machinery Manufacturers Institute (PMMI), newer tech in folder gluers has made it possible to work with a bunch of different materials at pretty high speeds — some models even reach up to 600 meters per minute! Knowing what materials your machine can handle isn’t just about boosting efficiency; it also helps cut down waste and operational costs, which is a big deal given how competitive the packaging game really is.

Automation vs. Manual Processes: Weighing the Pros and Cons

When you're trying to decide between automation and doing things manually in industries like packaging, it's really important to think about the unique perks and drawbacks each approach has. Automation—especially with cutting-edge tools like AI—can make workflows much smoother, boost productivity, and cut down on human mistakes. Did you know that roughly 40% of companies are already using AI in their operations? That’s a pretty big deal, and it shows how much potential there is for getting things done more efficiently. Automated systems are great at handling those boring, repetitive tasks quickly, which means employees get more time to focus on the really important, strategic stuff.

But on the flip side, manual processes still have their charm. They often offer a level of flexibility and direct oversight that some businesses need to keep things running smoothly. Sure, they might be slower and mistake-prone sometimes, but doing things manually allows for quick tweaks based on real-time feedback. Plus, for more complex or custom jobs, manual methods can be way more suitable. Figuring out the right mix between manual and automated work really depends on your specific needs and available resources. At the end of the day, it’s all about choosing what best supports your overall business goals.

Automation vs. Manual Processes in Folding and Gluing Packaging

Essential Maintenance Tips for Optimal Performance of Your Gluer

Keeping your automatic folder gluer in top shape really depends on regular maintenance—trust me, that stuff matters. According to a report by Smithers Pira, if you slack off on maintenance, you could see efficiency drop by as much as 30%. That’s a pretty big hit, leading to higher production costs and headaches all around. So, sticking to a solid maintenance schedule can make a huge difference in how well your machine works.

Here's a quick tip: make it a habit to check and clean all the parts regularly, especially the glue nozzle and folding mechanisms. Old glue buildup can slow things down and mess with your output—nobody wants that mess. Also, don’t forget to keep an eye on the machine’s calibration. When your gluer is properly calibrated, it can prevent misalignments that might ruin the final product. In fact, studies show that machines running at their best settings can crank out up to 20% more output.

At SHANGHAI EUREKA MACHINERY IMP. & EXP. CO., LTD., we totally get how important it is to keep your packaging equipment in great shape. Since our start back in 2007, we’ve grown to serve 88 countries, providing the latest solutions and expert support to keep your folder gluers running smoothly for years to come. Remember, regular care not only helps your machine last longer but also boosts the overall efficiency of your entire packaging operation.

Budgeting for Efficiency: Cost Considerations When Purchasing a Folder Gluer

Thinking about getting an automatic folder gluer? One of the biggest things to keep in mind is budgeting with efficiency in mind. Sure, the upfront cost can really vary depending on features, how fast it runs, and the brand’s reputation. But honestly, you don’t want to just focus on the sticker price. Sometimes, going for a higher-quality machine might cost more initially, but it can save you a ton in the long run—think lower labor expenses, less material waste, and faster production. It’s smart to consider the total cost of ownership, including maintenance, running costs, and possible downtime, so you can make a more informed decision financially.

Also, don’t forget to keep your actual production needs in mind when setting your budget. Take a good look at the volume of jobs you're handling and how complex the folding and gluing processes are. Cheaper machines can be tempting, I get it. But if they can’t handle your workload smoothly, those hidden costs—like overtime, rework, or unexpected halts—can end up costing you way more than you bargained for. So, when you're budgeting, it’s not just about finding something affordable. It’s about picking a machine that really fits your operation, helps you work efficiently, and boosts your productivity over the long haul.

Revolutionizing Packaging: The Ultimate Guide to Choosing the Right Automatic Folder Gluer

| Model | Production Speed (units/hour) | Max Sheet Size (mm) | Min Sheet Size (mm) | Price (USD) |

|---|---|---|---|---|

| Model A | 6000 | 1000 | 300 | 25,000 |

| Model B | 7500 | 1200 | 250 | 30,000 |

| Model C | 5000 | 900 | 200 | 22,000 |

| Model D | 6500 | 1100 | 280 | 28,000 |

| Model E | 7200 | 1150 | 260 | 32,000 |

Enhancing Print Quality and Efficiency: Insights from Market Reports on the HIS-1650W High Speed UV Spot and Overall Coating Machine

The HIS-1650W High Speed UV Spot and Overall Coating Machine represents a significant advancement in print quality and efficiency, addressing the increasing demand for high-performance finishing in the printing sector. Market reports indicate that the global demand for UV coating applications is on the rise, attributable to their ability to enhance aesthetics and durability of printed materials. The HIS-1650W machine accommodates a maximum sheet size of 1300mm x 1650mm, making it highly versatile for a variety of printing projects, from commercial prints to packaging solutions.

With an impressive speed of up to 5000 sheets per hour, the HIS-1650W stands out as a game-changer in production efficiency. This throughput significantly reduces turnaround times, providing printers with the agility needed to meet tight deadlines. Additionally, the machine is fitted with a robust power supply, offering 65kW for solvent-based coatings and 54kW for water-based options, allowing for optimal performance based on specific project requirements. According to industry analysts, investing in high-speed coating machinery like the HIS-1650W not only improves production capabilities but also enhances the overall quality of printed materials, thus contributing to higher customer satisfaction and retention rates in a competitive market.

FAQS

: Automation, particularly through advanced tools like AI, can significantly streamline workflows, enhance productivity, and reduce human error. It allows companies to handle repetitive tasks swiftly and frees up time for employees to focus on more strategic initiatives.

Manual processes can be slower and more prone to human error. However, they offer flexibility and the ability to make immediate adjustments based on real-time feedback, making them suitable for complex or customized tasks.

Companies should carefully consider their specific operational needs and the resources available to ensure that the chosen method aligns with their overarching business objectives.

Regular maintenance is crucial because improper maintenance can lead to a 30% decline in efficiency, resulting in increased production costs and diminished functionality of the gluer.

Regular inspection and cleaning of all components, especially the glue nozzle and folding mechanisms, and frequent monitoring of machine calibration are essential to maintain performance and prevent inconsistencies.

Inaccurate calibration can lead to misalignments that diminish output quality. Machines operating within their optimal settings can produce up to 20% more volume.

Neglecting regular maintenance can lead to decreased efficiency, higher production costs, and ultimately shorter lifespan of the equipment.

SHANGHAI EUREKA provides advanced solutions and expert support to ensure that folder gluers run smoothly, enhancing the overall efficiency and longevity of packaging operations.

Approximately 40% of companies have already started integrating AI into their operations to improve efficiency.

Automation allows employees to focus on more strategic initiatives by freeing them from repetitive tasks, thus enhancing productivity and allowing for more meaningful contributions.

Conclusion

When it comes to today’s fast-paced packaging world, picking the right automatic folder gluer isn’t just a technical decision — it’s a pretty big deal for your overall efficiency and the quality of your output. Think of this guide as your go-to resource; it walks you through the important stuff like size options, how fast the machines are, and whether they work well with different materials. These details really matter when you’re trying to find a machine that fits your specific production needs. Plus, we’ll dig into the whole automation versus manual debate, helping you figure out what’s best for your business.

Of course, keeping the machine running smoothly means paying attention to some easy maintenance tips — nobody wants unexpected breakdowns! And understanding how much you’re gonna need to invest upfront can save you a lot of headaches later on. As someone with solid experience in printing and packaging machinery, SHANGHAI EUREKA MACHINERY IMP. & EXP. CO., LTD is here to share useful insights and tailored solutions. Whether you're based in Europe, Asia, or Africa, they’ve got what it takes to help your company pick out the perfect automatic folder gluer.

Related Posts

-

How to Optimize the Performance of Your Vega Folder Gluer

-

Unlocking the Secrets of Offset Press Machines for Superior Printing Quality

-

Addressing Common Issues Faced by Laminator Users in Spanish Markets: A Data-Driven Perspective

-

5 Essential Tips for Selecting the Right Automatic Stamping Machine

-

5 Essential Tips for Maximizing Efficiency with Automatic Bottom Box Solutions in 2023

-

How to Transform Your Branding with Flexo-Graphics Techniques

Blog Tags: