How to Optimize the Performance of Your Vega Folder Gluer

Table of Contents

- Maximizing Efficiency: Understanding the Key Metrics of Vega Folder Gluer Performance

- Improving Productivity: The Impact of Speed and Throughput on Gluing Operations

- Material Matters: Analyzing the Effect of Substrate Types on Glue Performance

- Maintenance Strategies: Essential Practices to Extend the Life of Your Vega Folder Gluer

- Training the Team: Importance of Operator Skill Levels on Machine Efficiency

- Cost-Effectiveness: Evaluating the ROI of Upgrading Your Vega Folder Gluer Technology

- Revolutionizing Packaging Efficiency: Exploring the EF Series Large Format Automatic Folder Gluer

- FAQS

- Conclusion

- Related Posts

In the fast-paced world of printing and packaging, making sure your machinery is running smoothly is more important than ever — it’s key to keeping things efficient and ensuring your products look their best.

Take the Vega Folder Gluer, for example — it’s a pretty big deal on the production line because it helps with folding and gluing with precision and dependability. If you look at industry stats, manufacturers who really get the hang of fine-tuning their folding machines can see productivity jump by as much as 30%.

Here at SHANGHAI EUREKA MACHINERY IMP. & EXP. CO., LTD, which has been around since 2007, we’re proud to be a leading producer and exporter of printing and packaging equipment. Knowing how to get the most out of machines like the Vega Folder Gluer is crucial for staying competitive.

With our extensive network stretching across 88 countries in Europe, Asia, and Africa, we’re all about providing innovative solutions that help businesses boost their output and stay ahead of the curve in this ever-changing packaging market.

Take the Vega Folder Gluer, for example — it’s a pretty big deal on the production line because it helps with folding and gluing with precision and dependability. If you look at industry stats, manufacturers who really get the hang of fine-tuning their folding machines can see productivity jump by as much as 30%.

Here at SHANGHAI EUREKA MACHINERY IMP. & EXP. CO., LTD, which has been around since 2007, we’re proud to be a leading producer and exporter of printing and packaging equipment. Knowing how to get the most out of machines like the Vega Folder Gluer is crucial for staying competitive.

With our extensive network stretching across 88 countries in Europe, Asia, and Africa, we’re all about providing innovative solutions that help businesses boost their output and stay ahead of the curve in this ever-changing packaging market.

Maximizing Efficiency: Understanding the Key Metrics of Vega Folder Gluer Performance

If you really want your Vega folder gluer to perform at its best, understanding its

key performance metrics is a must. From what industry reports are saying,

cranking up the machine speed wisely can lead to pretty impressive gains—some companies have seen production jump up to

30%. The trick is to keep the speed just right, tailored to your specific setup.

Keeping an eye on real-time data like how evenly the glue is applied and how neat the folds are can really make a difference.

When operators stay aware of these things, they can tweak settings on the fly, making the workflow smoother and cutting down on

reworks and waste.

On top of that, machine downtime is a real efficiency killer. The latest stats show that fixing maintenance issues quickly can slash downtime by around

25%. Going for regular maintenance and even using predictive tools to spot potential problems early on can keep your

Vega gluer running at its best. These proactive steps not only save money but also help you meet deadlines more reliably, which makes your customers pretty happy. By paying attention to these

key metrics, your company can boost productivity and stay competitive in the busy packaging game. Honestly, it’s all about working

smarter, not just harder!

Improving Productivity: The Impact of Speed and Throughput on Gluing Operations

If you're serious about boosting your Vega Folder Gluer’s productivity, focusing on speed and how much you can push through is key. I read somewhere that just cranking up the gluing speed by around 10% can actually bump up your overall output by nearly 15%. The reason? Less machine downtime and a smoother flow of materials, which means your operators can hit tighter deadlines without sacrificing quality. Oh, and don’t forget—tuning your machine's settings properly can make a big difference too. When your gluer is dialed in just right, it minimizes waste and makes sure each step is done accurately, cutting down on errors that might slow things down.

And here’s a cool tip—adding real-time monitoring tools can really take things to the next level. Some industry studies suggest that by using advanced data tracking and analytics, facilities have managed to improve efficiency by 20 to 30%. When operators keep an eye on their workflow and performance data, they can spot bottlenecks early and tweak things on the fly. All of this really adds up—the more you optimize speed and throughput, the smoother your operations run, and it can really have a positive impact on your bottom line. Bottom line: if your goal is long-term growth, paying attention to these areas is pretty much unavoidable.

Material Matters: Analyzing the Effect of Substrate Types on Glue Performance

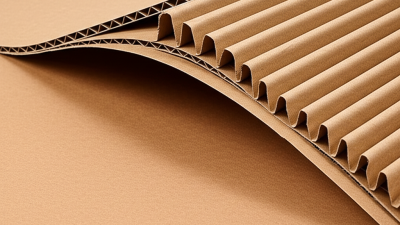

Picking the right type of substrate really matters when you're trying to get the best glue performance on a Vega folder gluer. You see, different materials just don’t interact with adhesives the same way, which can impact how strong the bond is, how quickly it dries, and overall how smoothly production goes. For example, some research shows that corrugated boards might need about 20 to 30% more glue compared to plain carton board to get the same bond strength. That just goes to show how important it is to choose the right substrate based on what you’re trying to achieve. Plus, the makeup and any treatments on the substrate can really change how much glue it absorbs, which in turn affects the quality of the finished product.

On top of that, how the adhesive bonds with the substrate depends a lot on things like surface energy and porosity. According to the folks at the Adhesive and Sealant Council, substrates with higher surface energy tend to create stronger bonds — sometimes up to 50% better adhesion if you match the right glue with the right surface. And using pre-treated substrates can give you a real edge, helping to prevent issues like delamination during folding. When you get a good grasp on these factors, it just makes sense — you can choose better materials, work more efficiently, and end up with a really high-quality, durable product.

Maintenance Strategies: Essential Practices to Extend the Life of Your Vega Folder Gluer

Taking good care of your Vega folder gluer is really key to keeping your production running smoothly and making sure the machine lasts a good long time. Regular maintenance isn’t just about avoiding breakdowns — it can actually save you a ton of money in the long run, and help your machine work more efficiently. Actually, industry folks have found that with proper upkeep, your machine's efficiency can bump up by as much as 40%, and you can cut down on downtime by almost 30%. That really shows how important it is to have a solid maintenance plan that's tailored to your specific machine.

One smart move is to set up a routine inspection schedule. This should include checking for any signs of wear on key parts, recalibrating settings when needed, and making sure the lubrication system is working its best. Plus, investing some time in training your team on how to properly operate the machine can make a big difference — it’s a simple way to prevent errors that could cause early wear and tear. Just like in other industries, like pool construction, where companies stress the importance of educating customers to keep their equipment in top shape, training your staff can really help your Vega folder gluer perform at its best. If you adopt these practices, you’ll not only protect your investment but also ensure your operations keep running smoothly day after day.

Training the Team: Importance of Operator Skill Levels on Machine Efficiency

Training the folks who operate your Vega Folder Gluer is absolutely crucial if you want to get the most out of it. I mean, in today's manufacturing world, the skill level of your operators really makes a big difference when it comes to how efficiently the machine runs. When operators are well-trained, they can better understand and use the latest tech and methods, which means fewer mistakes and less downtime. That, in turn, leads to faster production and higher quality products. Investing in good, thorough training isn't just about sharpening skills—it creates a culture where everyone keeps improving and learning new things.

Plus, with the rise of Human-Machine Interfaces (HMIs), the operator’s role has really changed. Now they need to get comfortable with smarter, connected systems. The truth is, a knowledgeable team can make the most of these advanced tools, helping your operation run smoother. It's a good idea for companies to focus on training, not only based on what skills their people have right now but also thinking ahead about what they’ll need in the future to stay ahead of the game. Doing this helps you stay competitive and makes sure your operators can handle the new, more complex manufacturing world we’re moving into.

How to Optimize the Performance of Your Vega Folder Gluer - Training the Team: Importance of Operator Skill Levels on Machine Efficiency

| Operator Skill Level | Training Hours | Average Speed (units/hour) | Waste Percentage (%) | Downtime (minutes) |

|---|---|---|---|---|

| Beginner | 20 | 150 | 15 | 30 |

| Intermediate | 50 | 200 | 10 | 20 |

| Advanced | 100 | 250 | 5 | 10 |

Cost-Effectiveness: Evaluating the ROI of Upgrading Your Vega Folder Gluer Technology

Thinking about upgrading your Vega folder gluer? It's really not just about making things run smoother — it's actually a smart move that can pay off big time. As the packaging world keeps changing, investing in the latest machinery can help you speed up production, cut down on waste, and boost your product quality. When you weigh the costs against the benefits, it's easier to see how these upgrades can align perfectly with what the market needs, ultimately giving your profits a nice boost.

Here at SHANGHAI EUREKA MACHINERY IMP. & EXP. CO., LTD, we totally get how crucial cool tech is for the success of printing and packaging businesses. We've been around since 2007 and have earned a good reputation as a top producer and exporter. We proudly ship high-quality machines to over 88 countries across Europe, Asia, and Africa. So, by investing in the latest Vega folder gluer, companies can not only make their processes smoother but also stay ahead of the game. It’s all about setting yourself up for long-term success in a pretty competitive, ever-changing market.

Revolutionizing Packaging Efficiency: Exploring the EF Series Large Format Automatic Folder Gluer

The EF Series Large Format Automatic Folder Gluer is a game-changer in the packaging industry, designed to enhance efficiency and streamline production processes. With its standard motorized plate adjustment feature, this advanced machine allows for rapid job changing, significantly reducing downtime and increasing productivity on the assembly line. This adaptability makes it an ideal solution for manufacturers looking to optimize their workflow and meet varying customer demands.

One of the standout features of the EF Series is its 2-side adjustable belt system, which effectively prevents the common issue of fish-tailing. This innovation ensures consistent and precise folding, leading to higher quality end products. Complemented by a robust size availability range from 1200 to 3200 mm, the EF Series can accommodate a diverse array of packaging requirements. With a maximum speed of 240 m/min and a 20mm frame on both sides for stable running, this folder gluer not only elevates productivity but also ensures smooth operation, fostering a reliable environment for high-volume production.

As industries evolve and the demand for efficient packaging solutions continues to grow, the EF Series stands out as an essential tool for manufacturers aiming to revolutionize their packing processes. By investing in this state-of-the-art machinery, companies can look forward to improved operational efficiency, quality, and the ability to adapt to changing market needs.

FAQS

: Key performance metrics include monitoring machine speed, glue application consistency, fold quality, and minimizing machine downtime through regular maintenance and predictive analytics.

Optimizing machine speed can lead to a significant enhancement in output, with some manufacturers achieving up to a 30% increase in production rates.

Addressing maintenance issues promptly can cut machine downtime by as much as 25%, which is critical for maintaining overall efficiency.

Different substrates interact with adhesives uniquely, affecting bonding strength and drying time, which is crucial for overall production efficiency.

Corrugated board substrates can require 20-30% more adhesive than carton board to achieve similar bond strength.

The adhesive's performance is influenced by substrate surface energy and porosity, where higher surface energy generally leads to stronger bonds.

Well-trained operators can significantly reduce errors and downtime, resulting in improved production rates and product quality.

HMIs require operators to adapt to smarter, interconnected systems, making it essential for them to be knowledgeable to maximize these advanced tools.

Comprehensive training enhances individual skill sets, fosters a culture of continuous improvement, and helps maintain a competitive edge in manufacturing.

By understanding key metrics, carefully selecting substrates, and training operators, manufacturers can enhance efficiency and produce high-quality outputs in their operations.

Conclusion

Making sure your Vega Folder Gluer runs smoothly and efficiently is pretty much essential if you want to boost productivity and get the most out of your gluing operations. Knowing the key numbers, like how fast it works and how much throughput you’re hitting, can really make a difference in how effective your machine is. Plus, don’t forget that the type of materials you use as substrates can have a big impact on how well the glue performs—so it’s worth taking the time to analyze how they affect things.

On top of that, keeping up with solid maintenance routines not only helps extend your machine’s lifespan but also keeps everything running at peak performance. Getting your team properly trained is just as important—experienced operators tend to squeeze more out of the machine and avoid costly hiccups. And when you’re thinking about upgrading your tech, it’s a smart move to weigh the return on investment so you can choose options that save you money in the long run and keep your printing and packaging processes humming.

Here at SHANGHAI EUREKA MACHINERY IMP. & EXP. CO., LTD, we’re all about offering innovative solutions that boost your machinery’s output and reliability—that’s what we’re here for!

Related Posts

-

What is an Automatic Cardboard Box Making Machine and How Does It Revolutionize Packaging?

-

Exploring Options for the Viena Seja Gofrētā Kartona Mašīna in Packaging Solutions

-

5 Essential Tips for Maximizing Efficiency with Automatic Bottom Box Solutions in 2023

-

Cardboard Laminators: A Comprehensive Comparison of Top Models for Global Buyers

-

How to Transform Your Branding with Flexo-Graphics Techniques

-

How to Choose the Right 1600mm High Speed Slitting Line for Your Factory Needs

Blog Tags: