10 Essential Tips for Using Die Cutter Paper Like a Pro

Table of Contents

- Choosing the Right Die Cutter for Your Paper Crafting Needs

- Understanding Different Types of Die Cuts and Their Applications

- Essential Materials for Successful Die Cutting Projects

- Techniques for Aligning and Securing Your Paper for Precision Cuts

- Tips for Maintaining and Cleaning Your Die Cutting Tools

- Creative Ways to Use Die Cuts in Your Craft Projects

- FAQS

- Conclusion

- Related Posts

Hey craft lovers and pros alike! We all know how crucial good tools are when you're trying to bring your creative ideas to life. And among them, Die Cutter Paper really stands out as a must-have. It’s super versatile and perfect for getting those detailed designs and crisp cuts just right. Whether you’re a seasoned pro or just dipping your toes into the paper arts scene, getting the hang of Die Cutter Paper can seriously take your projects up a notch. In this article, I’m gonna share the top 5 tips that will help you use Die Cutter Paper like a total boss.

We’ll walk through everything—choosing the right kind of paper, understanding how pressure and blades work, and the little tricks for keeping your tools in tip-top shape. With the boom in DIY crafts and personalized projects, knowing how to handle Die Cutter Paper effectively can really make your work stand out and open up a whole world of creative possibilities. So, get ready to level up your crafting game and turn your ideas into some pretty amazing, professional-looking projects!

Choosing the Right Die Cutter for Your Paper Crafting Needs

Choosing the right die cutter is crucial for achieving professional results in paper crafting. According to a report from the Craft and Hobby Association, 62% of crafters prioritize quality tools that enhance their creativity and efficiency. When selecting a die cutter, it’s essential to consider the type of projects you plan to undertake. For example, manual die cutters are preferred for small-scale projects, giving users more control and precision. In contrast, electronic die cutters offer advanced features such as automatic material detection and connectivity to design software, making them ideal for larger, more intricate projects.

Additionally, compatibility with various materials is another key factor. A survey by the Craft Industry Alliance revealed that 75% of crafters own multiple die cutters to accommodate different media, including cardstock, fabric, and even leather. When evaluating die cutters, look for models that can handle various thicknesses and types of materials. This versatility will save you time and expand your crafting possibilities, allowing for greater innovation in your projects. Ultimately, investing in the right die cutter can elevate your paper crafting experience and help you achieve stunning results that rival those of professional crafters.

Understanding Different Types of Die Cuts and Their Applications

Die cutting is a versatile technique used across various industries, and understanding the different types of die cuts can significantly enhance your crafting projects. There are several primary categories of die cuts, including basic shapes, intricate designs, and functional cuts like windows or tabs. Each type serves specific applications, from creating eye-catching invitations and packaging to producing customized product labels. For instance, precision in die cutting ensures that products not only look professional but also meet the stringent requirements of industries like retail and education.

As reported in the "Top 24 Applications of AI" article, the integration of technology into traditional crafting has transformed processes significantly. By utilizing automated die cutting machines, crafters can achieve consistent results at a higher speed, thereby merging creativity with efficiency. This is particularly evident in the online crafting community, where sellers quickly adapt to trends by employing advanced techniques that allow for a diverse range of products, from bespoke home decorations to personalized gifts. The ongoing evolution of tools and technology in die cutting mirrors the transformative impacts seen in various sectors, showcasing how even traditional crafts are influenced by modern advancements.

Essential Materials for Successful Die Cutting Projects

When diving into die cutting, the right materials can significantly impact the success of your projects. A recent study by the Craft and Hobby Association revealed that nearly 75% of crafters believe the quality of materials directly influences the outcome of their designs. Therefore, investing in high-quality paper and dies is crucial. For best results, consider using specialty papers such as cardstock, which provides a sturdy base for intricate cuts while maintaining clean edges.

Additionally, materials like felt and thin acrylic can offer exciting textures and effects that elevate a simple project to a professional level.

Moreover, selecting the appropriate adhesive and tools is equally important in the die cutting process. According to industry insights, utilizing the right adhesives can improve project longevity, ensuring that elements remain securely attached. For instance, double-sided tape or liquid glue designed for paper crafts can yield long-lasting results. Tools such as precision scissors, a craft knife, and cutting mats can enhance accuracy, leading to cleaner designs. By focusing on these essential materials, crafters can enhance not only their skills but also the overall aesthetic of their die-cut projects.

Techniques for Aligning and Securing Your Paper for Precision Cuts

Achieving precision in die cutting requires meticulous alignment and securing of your paper. According to a report by the Craft and Hobby Association, about 68% of hobbyists reported that improper alignment leads to wasted materials, increasing project costs. To avoid this common pitfall, start by ensuring your paper is cut to size and properly placed on the die cutter. Utilizing grid lines or alignment guides can significantly enhance your accuracy, helping you position your materials with greater confidence.

One effective technique for securing your paper is using low-tack tape. This not only keeps your material in place but also prevents any shifting during the cutting process, resulting in clean, precise edges. Further, consider pre-scoring your paper before die cutting; this prepares the fibers for a smoother cut and reduces the chance of tearing. These simple yet effective methods can make a substantial difference, with industry experts noting that a well-aligned setup can improve cutting accuracy by up to 40%.

Tips for Maintaining and Cleaning Your Die Cutting Tools

Maintaining and cleaning your die cutting tools is crucial for ensuring longevity and optimal performance. After each use, it's important to remove any paper scraps or debris that may have accumulated on the cutting plates or dies. A soft brush or a gentle cloth can effectively sweep away these remnants without causing damage. For more stubborn residues, you can use a mild soap solution and a damp cloth to clean the surfaces, ensuring to avoid any harsh chemicals that could harm the tool's fine surface.

In addition to regular cleaning, proper storage and maintenance of your die cutting tools can prevent rust and prolong their lifespan. Store blades and dies in a dry, cool place, preferably in protective cases or pouches to avoid unnecessary dulling or scratches. Lubricating the moving parts of your machine with a silicone spray can also keep everything functioning smoothly, further enhancing the efficiency of your die-cutter. By incorporating these practices into your routine, you can enjoy seamless die cutting sessions and keep your tools in top condition for all your crafting projects.

Creative Ways to Use Die Cuts in Your Craft Projects

Die cuts are a fantastic way to elevate your craft projects, offering endless creative possibilities. One of the most inventive ways to utilize die cuts is to create layered designs that add depth and dimension. Start by using multiple layers of die cuts in varying colors or textures to achieve a striking effect. Consider creating a beautiful floral arrangement where each layer showcases a different hue of your chosen flower. This technique not only brings your project to life but also allows for an engaging interaction with the audience as they explore the intricacies of your design.

Another exciting approach is to incorporate die cuts into home décor projects. Create custom wall art by arranging several die-cut shapes on a canvas or directly onto your wall. Using patterned papers or metallic card stock can instantly transform a mundane space into a vibrant showcase of your creativity. Additionally, consider using die cuts for personalized gifts like bookmarks or greeting cards. By tailoring each piece to the recipient's interests or special occasions, you create meaningful keepsakes that reflect both your artistic flair and personal touch.

FAQS

: High-quality paper such as cardstock, specialty papers, felt, and thin acrylic are essential. They provide a sturdy base, exciting textures, and elevate the overall quality of projects.

The right adhesive improves project longevity and ensures that elements stay securely attached. Double-sided tape and liquid glue designed for paper crafts are recommended for long-lasting results.

Precision scissors, a craft knife, and cutting mats are important tools that can enhance accuracy and lead to cleaner designs in your die-cut projects.

To avoid misalignment, ensure your paper is cut to size, use grid lines or alignment guides, and secure your paper properly before cutting.

Using low-tack tape is effective for securing paper, as it keeps materials in place and prevents shifting during cutting, resulting in clean edges.

Pre-scoring your paper prepares the fibers for a smoother cut and reduces the chance of tearing, leading to a more precise outcome.

About 75% of crafters believe that the quality of materials directly influences the success of their designs according to a study by the Craft and Hobby Association.

Improper alignment is a common issue that can lead to wasted materials, with around 68% of hobbyists reporting this problem, thereby increasing project costs.

A well-aligned setup can improve cutting accuracy by up to 40%, emphasizing the importance of meticulous alignment techniques.

Specialty papers offer not only sturdiness for intricate cuts but also enhance the texture and effects, contributing to a more professional look in die-cut projects.

Conclusion

In "10 Essential Tips for Using Die Cutter Paper Like a Pro," readers are guided through the essential aspects of die cutting for paper crafting. The article begins by emphasizing the importance of choosing the right die cutter based on individual crafting needs, considering the various types of die cuts available and their specific applications. It also highlights the essential materials required for successful projects, along with effective techniques for aligning and securing paper to ensure precision cuts.

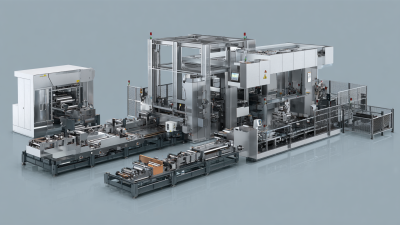

Furthermore, the article provides valuable maintenance and cleaning tips for die cutting tools, ensuring their longevity and optimal performance. Lastly, it inspires crafters with creative ways to incorporate die cuts into their projects, showcasing the versatility of Die Cutter Paper. With a rich history in the machinery industry, SHANGHAI EUREKA MACHINERY IMP. & EXP. CO., LTD recognizes the importance of quality tools in enhancing the crafting experience, further supporting the demand for efficient die cutting solutions in the global market.

Related Posts

-

What Makes a Cut Die Cutter Essential for Your Business

-

Revolutionizing Precision: The Future of Automatic Die Cutters in Modern Manufacturing

-

5 Essential Tips for Selecting the Right Automatic Stamping Machine

-

How to Efficiently Operate a Binding Wire Machine for Maximum Productivity

-

Mastering Precision: Top Paper Cutters for Perfect DIY Craft Projects Every Time

-

How to Choose the Best Paper Cutter 24 for Your Business Needs

Blog Tags: