How to Efficiently Operate a Binding Wire Machine for Maximum Productivity

Table of Contents

- Understanding the Basics of a Binding Wire Machine Functionality

- Essential Safety Measures to Implement While Operating the Machine

- Setting Up Your Binding Wire Machine for Optimal Performance

- Techniques to Maintain Consistent Wire Tension and Alignment

- Effective Troubleshooting Tips for Common Machine Issues

- Maximizing Efficiency in Document Binding: Insights from the 2023 Binding Equipment Market Report on the Automatic Wire O Binding Machine PBW580S

- FAQS

- Conclusion

- Related Posts

In today’s competitive world of printing and packaging machinery, boosting productivity isn’t just a goal — it’s absolutely essential for manufacturers, especially those using equipment like the Binding Wire Machine. I mean, recent reports show that the global packaging machinery market is expected to hit around USD 50 billion by 2027. A big chunk of that growth? Thanks to innovations in machinery like the Binding Wire Machine, which helps streamline those tricky operations and really ramp up output.

Here at SHANGHAI EUREKA MACHINERY IMP. & EXP. CO., LTD, we’ve been around since 2007, and honestly, we’re proud to be leading the charge in this industry. Our team is recognized by both industry pros and official bodies as one of the top producers and exporters out there. We’ve built quite a network too — spanning 88 countries across Europe, Asia, and Africa — all with the goal of delivering cutting-edge solutions that help businesses optimize their processes and hit new levels of productivity. It’s all about making sure our customers stay ahead of the game, and we’re here to support that every step of the way.

Understanding the Basics of a Binding Wire Machine Functionality

Getting a good grasp of how a binding wire machine works is pretty much key if you want to get the most out of your document binding. These machines are built to handle all sorts of materials, from simple paper to thicker stuff like cardboard — you name it.

How well a binding wire machine performs really depends on a few things: its mechanism, the kind of binding wire you're using, and whether it works well with different paper sizes. Interestingly, industry reports are pointing towards strong growth in the binding wire market. That’s mainly because more folks in schools and offices are looking for customized binding options these days.

Getting a good grasp of how a binding wire machine works is pretty much key if you want to get the most out of your document binding. These machines are built to handle all sorts of materials, from simple paper to thicker stuff like cardboard — you name it.

How well a binding wire machine performs really depends on a few things: its mechanism, the kind of binding wire you're using, and whether it works well with different paper sizes. Interestingly, industry reports are pointing towards strong growth in the binding wire market. That’s mainly because more folks in schools and offices are looking for customized binding options these days.

Basically, what makes these machines tick is their ability to punch holes and bind multiple sheets quickly and with decent precision. Medium-sized models are especially popular — they strike a good balance and can handle different binding tasks without slowing down. I remember reading a feasibility study for a client who wanted to start a mid-range binding wire plant, and it showed that investing in good quality machinery could cut down operational costs by about 20%. Plus, tech keeps improving, meaning new machines not only bind but also make the finished product sturdier and look a lot better, opening up more opportunities and boosting overall productivity.

Essential Safety Measures to Implement While Operating the Machine

Running a binding wire machine smoothly isn’t just about flipping switches—it’s really about staying safe and making sure everyone stays in one piece. At SHANGHAI EUREKA MACHINERY IMP. & EXP. CO., LTD, we get that safety comes first, especially since these machines run fast and handle some pretty heavy stuff.

First off, always gear up with the right protective gear—think gloves, safety glasses, and steel-toed boots. Trust me, a little protection goes a long way in avoiding cuts or crushed toes. Before you hit that start button, double-check that all safety guards are locked in place. It’s not just about keeping safe—it also helps your machine run better.

Here’s a tip: keep up with regular maintenance. Check the machine often and fix things early to prevent any sudden breakdowns. And don’t forget, training everyone on emergency procedures and proper handling makes a huge difference—it keeps accidents low and productivity high. When safety is a priority, everyone wins—more efficiency, less stress, and a happier work environment.

Setting Up Your Binding Wire Machine for Optimal Performance

Getting your binding wire machine set up the right way is really key if you wanna keep things running smoothly and get the job done efficiently. First off, pick a good spot for the machine—make sure it’s in a well-lit area, away from dust and debris because, trust me, that stuff can really mess with how well it works. Placing it on a stable surface helps a lot too, so you can reach the controls easily without any hassle. Also, try to position the machine close to your power source and where your materials are. It saves a bunch of time tweaking and moving stuff around.

After that, it’s time to calibrate the machine—adjust the tension and speed settings based on what kind of wire you’re using and how tight or strong you need the binding to be. Don’t forget to do regular checks and maintenance on parts like the rollers, cutters, and feed mechanisms. This way, you’ll avoid surprises or breakdowns right in the middle of a job. Making a habit of routine upkeep not only helps the machine last longer but also keeps everything working consistently. And hey, keeping your tools and supplies organized and within reach can seriously boost your workflow, so you can focus on getting that binding just right without wasting time hunting for stuff.

Techniques to Maintain Consistent Wire Tension and Alignment

Keeping the wire tension and alignment consistent is a really big deal when it comes to running a binding wire machine smoothly. I read somewhere that if the tension isn’t set properly, it can actually slow down production by up to 20%. So, it’s pretty important for operators to check and tweak the tension settings regularly—definitely before starting up a new batch. Using a tension gauge can be a game changer here, giving you real-time feedback so you can make those small adjustments on the fly. That way, you get a more even, reliable binding process, and it saves you headaches down the road.

Another thing that really makes a difference is keeping the alignment spot-on. If things aren’t aligned right, it can mess with the quality of your product and even cause more downtime because you’re constantly fiddling with stuff. According to the Manufacturing Institute, misaligned machines can cut your productivity by around 15%. A good tip is to do a quick alignment check at the start of each shift and then peek at it again halfway through production. If you’re into high-tech solutions, laser alignment systems can do a pretty great job of making sure everything’s perfectly lined up—less manual error, better precision, and better results overall. In the end, these little measures help produce consistent quality and can even save some cash on operational costs.

Effective Troubleshooting Tips for Common Machine Issues

Dealing with a binding wire machine can be pretty frustrating sometimes, especially when common issues pop up and throw a wrench in your workflow. One of the biggest headaches is wire jamming. That usually happens when the machine isn’t aligned just right or if some dirt or debris sneaks into the feed. To fix this, I’d recommend giving the machine a good regular check—look at the feed parts and clean out any dust or particles that might’ve accumulated. Making sure the wire is loaded properly and everything’s aligned can really help avoid those jams and keep things running smoothly.

Another thing to watch out for is inconsistent wire tension. If that’s off, the quality of the bindings can suffer, and no one wants sloppy work, right? The trick is to check the tension controls now and then and tweak them if needed. Keeping those tension settings calibrated will help you get a consistent, high-quality result every time. Plus, it’s a good idea to stay on top of routine maintenance and keep an eye on how the machine is performing overall. Doing this stuff regularly will help prevent headaches later on, keep the workflow flowing nicely, and boost your productivity in the long run.

Maximizing Efficiency in Document Binding: Insights from the 2023 Binding Equipment Market Report on the Automatic Wire O Binding Machine PBW580S

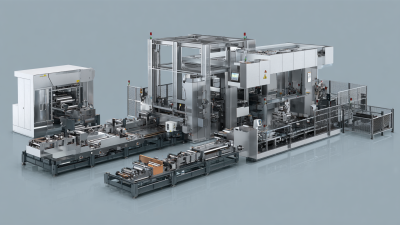

The automatic Wire O binding machine PBW580S represents a significant leap in efficiency for document binding, as highlighted in the 2023 Binding Equipment Market Report. This machine is specifically designed to streamline the binding process, featuring an integrated paper feeding system, hole punching capabilities, a secondary cover feeding mechanism, and a dedicated Wire O binding unit. These components work in unison to drastically reduce the time and labor required to produce high-quality wire-bound products.

With the PBW580S, businesses can significantly enhance their output for wire notebooks and wire calendars, making it an ideal choice for organizations aiming to automate their binding processes. The efficiency of this machine not only leads to increased production rates but also ensures consistency and precision in every finished product. By investing in the PBW580S, companies can meet growing demands while maintaining high standards of quality, ultimately leading to improved customer satisfaction and competitive edge in the market.

FAQS

: Maintaining consistent wire tension is crucial because improper tension can lead to production delays of up to 20%.

Operators can optimize wire tension by regularly checking the tension settings and making necessary adjustments before starting a production run, and by using a tension gauge for real-time feedback.

Misalignment can cause wasted materials and increased downtime, leading to a productivity decrease of approximately 15%.

Implementing systematic alignment checks at the beginning and during production cycles can help mitigate issues related to misalignment, leading to more consistent outputs.

Advanced alignment technologies, such as laser alignment systems, enhance precision and reduce manual errors, which can ultimately lower operational costs.

A common issue is wire jamming, often caused by improper alignment or foreign debris.

Operators can troubleshoot wire jamming by regularly inspecting the machine’s feed mechanisms, cleaning accumulated particles, and ensuring the wire is properly loaded and aligned.

Inconsistent wire tension can lead to poor binding quality; it can be addressed by checking and adjusting tension control settings regularly and calibrating the tension controls.

Routine maintenance is important as it helps prevent issues before they arise, ensuring smoother workflow and maximizing overall productivity.

Conclusion

The article titled "How to Efficiently Operate a Binding Wire Machine for Maximum Productivity" is a really helpful read for anyone looking to get the most out of their binding wire machines. It kicks off by giving a straightforward overview of what the machine does and then stresses the importance of safety precautions—because, let’s be honest, safety first, right? From there, it walks you through how to set up the machine properly so it runs smoothly and efficiently. It also shares some handy tips on keeping the wire tension and alignment just right—those little details really make a difference when you're aiming for top-notch quality.

Plus, the piece doesn’t leave you hanging when things go wrong. It offers practical troubleshooting advice to help you tackle common hiccups during operation. Honestly, if you follow these tips, you’ll not only boost your productivity but also extend the life of your machine. And it all aligns with the high standards set by SHANGHAI EUREKA MACHINERY IMP. & EXP. CO., LTD—who are pretty well-known for their quality in printing and packaging equipment.

Related Posts

-

5 Essential Tips for Selecting the Right Automatic Stamping Machine

-

Addressing Common Issues Faced by Laminator Users in Spanish Markets: A Data-Driven Perspective

-

How to Choose the Right 1600mm High Speed Slitting Line for Your Factory Needs

-

Cardboard Laminators: A Comprehensive Comparison of Top Models for Global Buyers

-

How to Transform Your Branding with Flexo-Graphics Techniques

-

Exploring Options for the Viena Seja Gofrētā Kartona Mašīna in Packaging Solutions

Blog Tags: