How to Choose the Best Digital Cutter Machine for Your Business Needs

Table of Contents

- Understanding Digital Cutter Machines: Types and Functions

- Key Features to Consider in Digital Cutter Selection

- Evaluating Cutting Speed and Precision in Digital Cutters

- Analyzing Cost vs. Performance: ROI of Digital Cutting Solutions

- Market Trends in Digital Cutting Technology: What to Expect

- Choosing the Right Software Compatibility for Your Digital Cutter

- Efficient Edging Solutions: The Versatile SLG-850-850L Corner Cutter & Grooving Machine

- FAQS

- Conclusion

- Related Posts

Let's be honest — in today’s super busy business world, picking the right tools can really make or break your efficiency and the quality of your work. One piece of equipment that a lot of businesses swear by is the Digital Cutter Machine. As industries keep changing and advancing, so do the demands for faster, more precise, and versatile cutting tech. With so many options out there, it can honestly be pretty overwhelming trying to find that perfect Digital Cutter Machine that fits your specific needs.

In our '2025 Top+ Digital Types' guide, we’re gonna break down everything you need to think about before making a decision. From how well it cuts to how easy it is to use, to whether it plays nicely with your existing software and what kind of maintenance it needs — we’ll cover it all. Plus, we’re spotlighting some of the top brands leading the charge in digital cutting solutions. The idea is that, by understanding all these bits, you can confidently choose a Digital Cutter Machine that not only boosts your productivity but also lines up with your bigger, long-term goals.

Understanding Digital Cutter Machines: Types and Functions

Digital cutter machines have become essential tools in various industries, from packaging to signage and textiles. Understanding the different types of digital cutters is crucial for businesses looking to invest wisely. The two primary categories are flatbed cutters and roll-fed cutters. Flatbed cutters, often used in the packaging and signage sectors, provide precision cutting for rigid materials, making them ideal for intricate designs and prototypes. In fact, a report from Smithers Pira highlights that the demand for flatbed cutters is projected to grow at a CAGR of 5.2% by 2026, driven by innovation in materials and applications.

On the other hand, roll-fed cutters are preferred in the graphics and textile industries due to their ability to handle flexible materials efficiently. These machines excel at high-speed production and are vital for creating banners, labels, and apparel. According to an analysis by Technavio, the roll-fed segment is expected to experience a surge in sales, with anticipated growth of 6.8% annually through 2025. Understanding these functionalities allows businesses to match their operational needs with the right digital cutter machine, ultimately enhancing productivity and reducing overhead costs.

Key Features to Consider in Digital Cutter Selection

When selecting a digital cutter machine for your business, there are several key features to consider that can significantly impact your efficiency and productivity. First, evaluate the cutting speed and accuracy of the machine. A high-speed cutter with precision capabilities will streamline your operations, particularly in industries such as printing and packaging where time and quality are paramount. Additionally, consider the machine’s compatibility with various materials; versatility in cutting different substrates can enhance your service offerings and appeal to a broader client base.

Another important factor is the ease of use and maintenance. A user-friendly interface can reduce training time for your staff, while regular maintenance requirements should be manageable to ensure minimal downtime. Investing in a machine that combines advanced technology with straightforward operation will not only improve your workflow but also support your business growth. As a trusted name in the printing and packaging sector, SHANGHAI EUREKA MACHINERY IMP. & EXP. CO., LTD offers a range of digital cutters designed with these essential features, catering to the diverse needs of businesses across 88 countries.

Evaluating Cutting Speed and Precision in Digital Cutters

When selecting a digital cutter machine for your business, evaluating cutting speed and precision is critical to ensuring efficiency and quality. Cutting speed, measured in inches per second, determines how quickly the machine can process materials. Businesses with high-volume production demands should prioritize machines that offer faster cutting speeds without compromising on accuracy. A balance between speed and quality can dramatically enhance productivity while reducing operating costs.

Precision in cutting is equally important, particularly for tasks that require intricate designs or tight tolerances. High-quality digital cutters utilize advanced technology, such as laser or blade precision, to achieve clean, sharp cuts consistently. When assessing a digital cutter, consider its capability to handle various materials and thicknesses, as well as features like automated calibration or software support that enhance precision. The right balance of cutting speed and precision will ultimately contribute to a smoother workflow and better final products, aligning the equipment with your specific business needs.

How to Choose the Best Digital Cutter Machine for Your Business Needs

| Machine Type | Cutting Speed (cm/s) | Cutting Precision (mm) | Maximum Cutting Area (cm²) | Material Compatibility |

|---|---|---|---|---|

| Flatbed Cutter | 100 | 0.1 | 2000 | Paper, Vinyl, Cardboard |

| TANGENTIAL Cutter | 50 | 0.05 | 1500 | Fabrics, Thin Plastics |

| Roll Cutter | 80 | 0.2 | 3000 | Vinyl, Paper, Textiles |

| Laser Cutter | 90 | 0.03 | 1000 | Acrylic, Wood, Paper |

Analyzing Cost vs. Performance: ROI of Digital Cutting Solutions

When selecting a digital cutter machine for your business, understanding the balance between cost and performance is crucial. The return on investment (ROI) of digital cutting solutions can vary significantly based on your specific needs and usage patterns. A lower-cost machine may seem attractive but could lack the durability or precision required for high-volume projects, ultimately leading to increased costs in the long run. On the other hand, investing in a higher-end model can enhance productivity and reduce material waste, providing better overall value.

Tips: Before purchasing, evaluate your project requirements thoroughly. Consider factors such as the types of materials you will be cutting, the complexity of designs, and how often you'll need to operate the machine. It may also be beneficial to look into customer reviews and case studies from similar businesses to determine which machines have proven to provide a solid ROI.

Additionally, factor in maintenance costs and the potential for future upgrades when making your decision, as these can drastically impact your long-term investment. Ultimately, weighing the upfront costs against the expected performance and longevity can help you make a well-informed choice that aligns with your business goals.

Market Trends in Digital Cutting Technology: What to Expect

As the digital cutting technology market evolves, staying informed about current trends is essential for businesses seeking the right equipment. One significant trend is the rapid growth of the metal cutting tools market, expected to rise from $86.24 billion in 2025 to $141.65 billion by 2032, with a compound annual growth rate (CAGR) of 7.3%. This surge is driven by the increasing demand for precision cutting and manufacturing efficiency across various industries.

When choosing the best digital cutter for your business needs, consider the following tips: First, research the functionality and versatility of different machines. Look for models that can handle various materials and cutting styles to maximize your production capabilities. Second, pay attention to the software compatibility of the digital cutter. Advanced algorithms and software integrations can significantly enhance your cutting precision and workflow efficiency.

Another notable area is the growth of the POS printer market, projected to grow from $665.94 million in 2025 to $374.44 million by 2033. Understanding these market shifts can help businesses align their equipment choices with future demand and technology advancements. Keeping an eye on emerging trends will ensure your investment in digital cutting technology is both timely and profitable.

Choosing the Right Software Compatibility for Your Digital Cutter

When selecting a digital cutter machine for your business, ensuring software compatibility is crucial for maximizing its potential. Different cutting machines come with varying levels of software support, which can significantly affect your workflows. It's essential to evaluate the software packages offered with the cutter to guarantee they align with your existing design tools and production methods. Look for machines that support popular design software like Adobe Illustrator or CorelDRAW, as this will allow for a smoother integration into your current processes.

Additionally, consider the types of materials you will be cutting and whether the compatible software can handle specific formats or file types. Advanced software features such as nesting, layout optimization, and real-time previews can enhance your efficiency and accuracy. Ensure that the software associated with the cutter includes regular updates and customer support, which can help resolve any issues that arise and keep your operations running smoothly. By prioritizing software compatibility, you can ensure that your digital cutter is not just a piece of equipment, but a valuable asset to your business.

Digital Cutter Machine Software Compatibility

This chart illustrates the compatibility scores of various software options for digital cutter machines. A higher score indicates better compatibility, helping businesses choose the right software for their specific digital cutter needs.

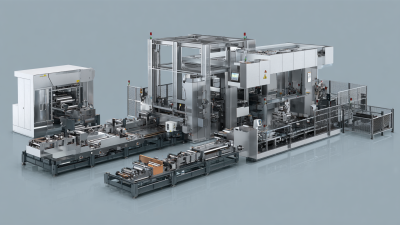

Efficient Edging Solutions: The Versatile SLG-850-850L Corner Cutter & Grooving Machine

The SLG-850-850L Corner Cutter & Grooving Machine stands out in the industry for its efficiency and versatility, addressing the diverse needs of modern fabricators. Designed to cater to various material sizes, the SLG-850 model accommodates materials up to 550x800mm, while the SLG-850L expands this capacity to an impressive 650x1050mm. Both models support a minimum material size of 130x130mm, making them suitable for a wide range of projects. Particularly impressive is the capability to handle thicknesses from 1mm to 4mm, providing users with flexibility in their operations.

Accuracy is crucial in any cutting and grooving process, and the SLG-850-850L does not disappoint. With a normal grooving accuracy of ±0.1mm and the ability to achieve a best accuracy of ±0.05mm, users can rely on consistent, high-quality results. The machines are designed for speed as well, processing 100-110 pieces per minute with a single feeder, ensuring that production timelines are met without sacrificing performance. The corner cutting feature can handle lengths as short as 13mm, making these machines ideal for intricate designs and detailed work. Overall, the SLG-850-850L range brings unparalleled efficiency and precision to corner cutting and grooving tasks, solidifying their place as essential tools in any workshop.

FAQS

: Key features to consider include cutting speed and accuracy, material compatibility, ease of use, and maintenance. These factors can significantly impact efficiency and productivity in your operations.

Cutting speed and precision are critical for ensuring efficiency and quality. Faster cutting speeds are preferable for high-volume production, while precision is necessary for intricate designs and tasks requiring tight tolerances.

Software compatibility is essential for maximizing the cutter's potential. Ensuring that the cutter supports popular design software can facilitate smoother integration into existing production methods.

A digital cutter should be versatile enough to cut various materials and thicknesses, which can enhance service offerings and appeal to a broader client base.

Look for advancements such as laser or blade precision, automated calibration, and features that enhance workflow, such as layout optimization and real-time previews in associated software.

A user-friendly interface can reduce staff training time and facilitate smoother operations. Machines that combine advanced technology with straightforward operation can improve workflow and support business growth.

Advanced software features such as nesting, layout optimization, and regular updates can improve accuracy, efficiency, and overall performance by aligning design processes with production capabilities.

Manageable maintenance requirements are vital to ensure minimal downtime, which contributes to consistent operations and overall productivity in a business setting.

A balance between cutting speed and accuracy can dramatically enhance productivity, which in turn can lead to reduced operating costs in high-volume production environments.

Evaluate the cutter's technology, such as whether it uses laser or blade precision, and check for features that support various materials and thicknesses to ensure it meets your specific needs.

Conclusion

Choosing the right Digital Cutter Machine for your business is essential to enhance production efficiency and meet specific needs. Understanding the different types and functions of digital cutters lays the groundwork for selection, as businesses must consider key features such as cutting speed, precision, and software compatibility. Evaluating the cost versus performance will help determine the return on investment (ROI) for digital cutting solutions, ensuring that companies can stay competitive in a rapidly evolving market.

Market trends indicate advancements in digital cutting technology, which businesses should keep a close eye on to make informed decisions. As an established leader in the printing and packaging machinery sector, SHANGHAI EUREKA MACHINERY IMP. & EXP. CO., LTD understands these dynamics and offers a range of digital cutter solutions tailored to meet the diverse requirements of clients across Europe, Asia, and Africa.

Related Posts

-

Unlocking Efficiency: How Lamina Gluer Technology is Revolutionizing the Packaging Industry

-

Exploring the Etymology and Uses of 'Gluer': Unraveling the True Meaning Behind This Intriguing Term

-

Unlocking the Secrets of Offset Press Machines for Superior Printing Quality

-

Addressing Common Issues Faced by Laminator Users in Spanish Markets: A Data-Driven Perspective

-

5 Essential Tips for Selecting the Right Automatic Stamping Machine

-

How to Transform Your Branding with Flexo-Graphics Techniques

Blog Tags: