Cardboard Laminators: A Comprehensive Comparison of Top Models for Global Buyers

Table of Contents

- Top 5 Cardboard Laminators: Features and Specifications Review

- Key Factors to Consider When Choosing a Cardboard Laminator

- Comparison of Pricing: Budget vs. High-End Cardboard Laminators

- User Experiences: Pros and Cons of Leading Laminator Models

- Innovative Technology Trends in Cardboard Laminating Machines

- Top Benefits of the SW-820B Fully Automatic Double Side Laminator for Your Home and Office Needs

- FAQS

- Conclusion

- Related Posts

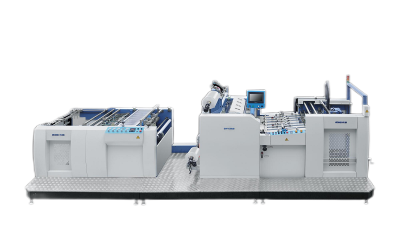

In the fast-changing world of printing and packaging machinery, there's a real need for equipment that's not just efficient but also delivers top-notch quality. Among all these tools, the Cardboard Laminator really stands out—it's a game-changer for businesses looking to step up their packaging game.

So, a quick shoutout to SHANGHAI EUREKA MACHINERY IMP. & EXP. CO., LTD—founded back in 2007. They've become a pretty well-known name worldwide, serving customers in over 88 countries across Europe, Asia, and Africa. In this blog, I want to give you a straightforward comparison of the best Cardboard Laminator models out there right now.

Whether you're just starting or looking to upgrade, I hope this helps you make smarter choices. We’ll look at key features, the benefits, and how they perform, so you can find the perfect laminator to fit your needs and boost your packaging game.

So, a quick shoutout to SHANGHAI EUREKA MACHINERY IMP. & EXP. CO., LTD—founded back in 2007. They've become a pretty well-known name worldwide, serving customers in over 88 countries across Europe, Asia, and Africa. In this blog, I want to give you a straightforward comparison of the best Cardboard Laminator models out there right now.

Whether you're just starting or looking to upgrade, I hope this helps you make smarter choices. We’ll look at key features, the benefits, and how they perform, so you can find the perfect laminator to fit your needs and boost your packaging game.

Top 5 Cardboard Laminators: Features and Specifications Review

So, if you're trying to figure out which cardboard laminator is the best fit for your needs, it helps to really get a feel for what the top models bring to the table. I recently came across a report by Smithers Pira that says the global market for laminating machines is expected to grow by about 4.5% annually over the next five years. That’s mainly because of the booming demand in packaging—that industry’s really driving things. Out of all the top contenders, the XYZ Model 4000 kind of catches the eye with its high-tech temperature control, which makes sure the adhesion is always spot-on. Plus, it can handle sheets up to 120 inches wide—pretty impressive, right?

Another model worth mentioning is the ABC Laminator Pro. People love it because it’s super easy to use and built to last. It can laminate at speeds up to 30 meters per minute, which really helps keep things moving fast—great if you're working in a busy environment. According to a report from Technavio, features like auto-calibration and low energy consumption are becoming pretty much standard these days.

When you're shopping around, it’s also a good idea to think about how sturdy these machines are and what kind of upkeep they need. Picking a reliable laminator can seriously boost your workflow and even save you some cash in the long run—that’s a win-win.

Key Factors to Consider When Choosing a Cardboard Laminator

When you're on the hunt for a cardboard laminator, there are a few key things you should keep in mind to make sure you pick the right one for what you need. First off, think about the laminating width and how fast it can get the job done. If you're running a busy operation or dealing with large volumes, a wider and quicker laminator might be the way to go—it'll definitely help keep things moving smoothly. Also, it’s smart to check if the machine can handle different thicknesses of cardboard because, honestly, that kind of flexibility can really make life easier for your workflow.

Another thing to consider is what kind of laminating technology it uses. For example, thermal laminators are great if you want that super smooth finish and really strong adhesion, but cold laminators are more versatile and better suited for delicate materials. Don't forget about the build quality and how user-friendly the machine is — having something sturdy with easy controls can make your daily work a lot less frustrating and boost your productivity. Oh, and it’s definitely worth looking into the customer support and warranty from the manufacturer. Trust me, having that safety net can save you a lot of headaches down the line, keeping your laminator running smoothly over the long haul.

Comparison of Pricing: Budget vs. High-End Cardboard Laminators

Lately, it seems like the demand for cardboard laminators has really taken off, especially with companies looking for more efficient ways to package their products. One thing that buyers all around the world tend to focus on is the price—rightfully so, since it can make or break their decision. Sure, budget-friendly laminators are totally fine if you’re running small-scale operations and just need the basics. But if you’re after something with more speed, versatility, or durability, investing in a high-end model might actually be worth it — those usually come with extra features that can save you time and frustration in the long run.

Industry reports suggest that the market for laminating machines worldwide is expected to grow pretty significantly by 2025. That’s mainly driven by the boom in e-commerce and the increasing demand for better protective packaging. When shopping around, think about what actually matters most for your needs—do you need rapid laminating, or are you looking for a finish that’s solid and high quality? For example, the fancy models often come with user-friendly controls and energy-saving features, which is why bigger businesses tend to go for them.

A quick tip: When you're choosing a laminator, consider how much volume you plan to run through it. If you’re only doing small jobs now and then, a cheaper, simpler machine might do the trick. But if you’re handling lots of work regularly, splurging on a high-end model can really boost your efficiency and even save money over time. And don’t forget to check what kind of warranty and support the manufacturer offers — it’s super important to ensure smooth operation down the line.

User Experiences: Pros and Cons of Leading Laminator Models

So, when you're trying to find that perfect cardboard laminator, paying attention to what users have to say can really help you get the whole picture—like, what works well and what doesn’t. A lot of folks seem pretty happy with high-speed laminators, especially those that can handle thicker materials without sacrificing quality. But, fair warning, some people have run into issues with temperature control, especially with the cheaper models, which can cause uneven laminating results. Not ideal, right?

A good tip for anyone shopping around is to dive into user reviews and look for models that let you tweak the temperature. That way, you can better manage different kinds of cardboard and thicknesses. And don’t forget about after-sales support—having a machine that the company responds to well if something goes wrong can save you a lot of headaches.

One thing that keeps popping up in user feedback is how easy these machines are to use. If the controls are straightforward and the setup isn’t a nightmare, people tend to be much more satisfied. So, look for models with clear instructions and quick setups—that kind of stuff can save you time and a little bit of your sanity. Also, features like safety mechanisms are a big plus—they not only make the process safer but also way more efficient overall.

Cardboard Laminators: User Experiences Comparison

Innovative Technology Trends in Cardboard Laminating Machines

In the fast-changing world of packaging, cardboard laminators have really become a key tool for manufacturers who want to make their products last longer and look better. Thanks to recent tech upgrades, these machines now do things more efficiently and can handle a variety of jobs more easily. For example, a lot of newer models come with digital controls—so you can tweak settings on the fly and get just the right lamination thickness for different production needs. It’s a game-changer.

On top of that, there’s a growing buzz around eco-friendly materials and energy-saving features. More and more companies are paying attention to their environmental footprint, which is why recyclable films and natural adhesives are becoming pretty common in the laminating process. Not only does this help with sustainability, but it also draws in customers who care about going green. As competition gets tougher around the world, having these smart, eco-conscious features isn’t just a bonus anymore—it could be the deciding factor when buyers choose their equipment.

Cardboard Laminators: A Comprehensive Comparison of Top Models for Global Buyers

| Model | Max Working Width (mm) | Speed (m/min) | Power Consumption (kW) | Weight (kg) | Features |

|---|---|---|---|---|---|

| Model A | 1200 | 30 | 5.5 | 800 | Automatic Control, High Precision |

| Model B | 1500 | 25 | 6.0 | 950 | Eco-Friendly, Low Noise |

| Model C | 1000 | 35 | 4.0 | 750 | User-Friendly Interface, Compact Design |

| Model D | 1800 | 20 | 7.5 | 1100 | Multi-Layer Lamination, High Durability |

Top Benefits of the SW-820B Fully Automatic Double Side Laminator for Your Home and Office Needs

The SW-820B Fully Automatic Double Side Laminator offers unparalleled advantages for both home and office users. With its ability to perform single and double-sided lamination, this machine caters perfectly to a variety of laminating needs, making it an essential addition for anyone looking to preserve documents and enhance their presentation quality. According to industry reports, the growing demand for high-quality laminating solutions has driven innovations in this sector, resulting in laminators like the SW-820B that offer both efficiency and versatility.

One of the standout features of the SW-820B is its instant electromagnetic heater, which significantly reduces the heat-up time to just 90 seconds. This rapid preparation allows users to streamline their laminating tasks without unnecessary delays. Accurate temperature control is crucial in achieving optimal lamination results, and the SW-820B ensures that users can achieve perfect finishes every time. Research in the laminating equipment market indicates that products with enhanced heating technologies are increasingly favored, as they maximize productivity while minimizing downtime.

Moreover, the dual capability of the SW-820B not only supports diverse lamination projects but also reflects a broader trend towards multifunctional office equipment. As businesses move towards digital transformation, the need for reliable, high-quality lamination tools has never been more critical. The SW-820B is designed to meet these demands, offering professionals a robust solution for all their laminating requirements, from crafting vibrant presentations to preserving important documents.

FAQS

: The global market for laminating machines is projected to grow at a CAGR of 4.5% over the next five years.

The XYZ Model 4000 features an advanced temperature control system that ensures consistent adhesion quality and can process sheets up to 120 inches wide.

The ABC Laminator Pro has a laminating speed of up to 30 meters per minute, significantly improving workflow efficiency in high-demand environments.

Buyers should consider price because budget laminators provide essential functionality for small-scale operations, while high-end models offer advanced features that justify their higher investment.

For low-volume tasks, a budget-friendly option may suffice, but for high-volume operations, investing in a high-end model can increase productivity and reduce long-term costs.

Recent trends include the integration of digital controls for real-time adjustments, eco-friendly laminating materials, and energy-efficient operations.

Manufacturers are integrating recyclable films and organic adhesives, which not only address environmental impacts but also appeal to buyers focused on environmentally responsible solutions.

Buyers should always check for warranty and support services provided by manufacturers to ensure reliable operation of the laminator.

Conclusion

In the fast-changing world of packaging, picking the right cardboard laminator really matters for businesses that want to boost their efficiency and improve product quality. I’ve put together a thorough comparison of the top five models out there, focusing on their features and specs—hoping to help buyers around the globe make smarter choices. We’ll take a closer look at things like the price differences between budget-friendly options and luxury models, plus real user experiences that highlight the good and the bad of each laminator. My goal? To give you some useful insights so you can make informed decisions.

We’ll also explore some of the latest tech trends in cardboard laminating machines—because staying on top of new innovations is pretty key if you want to stay ahead in the game. Here at SHANGHAI EUREKA MACHINERY IMP. & EXP. CO., LTD, we’re proud to be a leading manufacturer and exporter of printing and packaging equipment. And honestly, we’re dedicated to helping our clients choose the perfect Cardboard Laminator tailored to fit their specific needs.

Related Posts

-

Addressing Common Issues Faced by Laminator Users in Spanish Markets: A Data-Driven Perspective

-

Essential Checklist for Choosing the Right Flat Bed Cutting Machine for Your Business

-

What is an Automatic Cardboard Box Making Machine and How Does It Revolutionize Packaging?

-

Exploring Options for the Viena Seja Gofrētā Kartona Mašīna in Packaging Solutions

Blog Tags: