Understanding the Benefits of Stack Paper Cutters in Modern Printing Workflows

Table of Contents

- Advantages of Stack Paper Cutters in Enhancing Efficiency in Printing

- Key Features of Modern Stack Paper Cutters for Streamlined Workflows

- Comparing Stack Paper Cutters to Traditional Trimming Methods

- Innovative Technologies in Stack Paper Cutters for Precision Cuts

- Cost-Effectiveness of Using Stack Paper Cutters in High-Volume Printing

- Integrating Stack Paper Cutters into Digital Printing Systems for Optimal Results

- Maximizing Efficiency in Your Workspace: The Benefits of the GW-S High Speed Paper Cutter

- FAQS

- Conclusion

- Related Posts

In today’s fast-changing world of printing, upgrading to newer, smarter equipment has become pretty much essential if you want to boost your productivity and produce top-quality results. One piece of machinery that’s really made a difference is the Stack Paper Cutter. It’s changed the game for modern printers by providing precise, reliable cuts, whether you’re working on small jobs or big runs. According to a recent report from Smithers Pira, the global market for paper cutters is expected to grow at about 3.5% annually from 2023 to 2028. That just shows how much more companies are relying on advanced cutting tech to stay ahead.

James Reynolds, CEO of Precision Cutting Solutions and an industry veteran, puts it simply: “The efficiency you get from using a Stack Paper Cutter is huge. It streamlines the whole workflow, cuts down on waste, and speeds up turnaround times — it’s a total game-changer.” These cutters let printers handle larger stacks of paper quickly and accurately, making them pretty much a must-have for anyone serious about improving their operations.

And it’s not just about efficiency — these cutters also help save money by reducing wasted material. That’s a big deal, especially with how much the industry is pushing towards greener, more eco-friendly printing practices. Basically, investing in good cutting technology isn’t just smart for business, it’s also a step towards being more environmentally responsible. Companies that want to stay competitive and meet today’s standards really need to consider this kind of tech.

Advantages of Stack Paper Cutters in Enhancing Efficiency in Printing

Stack paper cutters have become essential tools in modern printing workflows, significantly enhancing efficiency. One of the primary advantages is their ability to handle large volumes of paper simultaneously. This capability allows operators to cut multiple stacks, drastically reducing the time spent on finishing tasks. By automating and streamlining the cutting process, printers can free up valuable manpower and allocate resources to other critical areas, such as design and production.

Moreover, stack paper cutters provide precision that manual cutting methods simply cannot match. With advanced technology and sharp blades, these machines ensure clean, accurate cuts every time, leading to better-quality finished products. Consistency in cut size minimizes waste, thus contributing to cost savings. Additionally, many modern stack cutters come equipped with programmable settings that allow for easy adjustments based on specific project needs, making them highly versatile in various printing applications.

Overall, the integration of stack paper cutters into the printing workflow represents a significant leap towards achieving higher productivity and efficiency.

Key Features of Modern Stack Paper Cutters for Streamlined Workflows

In modern printing workflows, stack paper cutters have become indispensable tools, enhancing efficiency and precision. One of the key features of contemporary stack paper cutters is their automated cutting capabilities. According to a report by Smithers Pira, the global demand for automated cutting equipment is expected to grow by 5.2% annually through 2025, underscoring the shift towards automation in the printing industry. This automation not only increases throughput but also minimizes the risk of human error, ensuring that each cut is clean and precise.

Another significant feature of modern stack paper cutters is their ability to handle varying paper sizes and types effectively. Many advanced models come equipped with adjustable cutting blades and programmable settings that can accommodate anything from delicate paper stock to thick cardstock. A study by the Printing Industries of America indicates that 85% of print service providers reported improved workflow efficiency when utilizing versatile cutting tools. This adaptability is crucial in today’s fast-paced printing environments, where the ability to quickly switch between jobs can significantly enhance productivity and customer satisfaction.

Comparing Stack Paper Cutters to Traditional Trimming Methods

Stack paper cutters have become increasingly popular in modern printing workflows, especially when compared to traditional trimming methods. Unlike manual trimmers that require considerable time and effort, stack paper cutters streamline the cutting process by allowing large quantities of paper to be trimmed at once. This efficiency not only speeds up production but also reduces the risk of human error, which is common with manual cutting techniques.

When using a stack paper cutter, it's essential to maximize its effectiveness. **Tip 1:** Always ensure that the blades are sharp and well-maintained; dull blades can lead to uneven cuts and damaged paper edges. **Tip 2:** Utilize an appropriate cutting stick beneath the paper stack to preserve the cutter's blades and achieve cleaner cuts. Traditional trimming methods often involve repetitive handling of each sheet, increasing the likelihood of misalignment and inconsistent results. With stack paper cutters, users can achieve uniformity in their projects, enhancing the overall quality of the printed materials.

Moreover, stack paper cutters typically come equipped with safety features that are lacking in traditional trimmers. **Tip 3:** Familiarize yourself with the safety mechanisms to prevent accidents while operating the equipment. By investing in modern cutting technology, printing professionals can transition to more efficient workflows, making the entire process smoother and more reliable.

Innovative Technologies in Stack Paper Cutters for Precision Cuts

The advancements in stack paper cutters have significantly transformed modern printing workflows, particularly through the integration of innovative technologies aimed at achieving precision cuts. According to a 2022 report by Smithers Pira, the global market for automated cutting solutions is projected to reach $450 million by 2026, driven by the growing demand for efficiency and accuracy in printing operations. This rise in automation has led to the development of stack paper cutters equipped with advanced features such as laser cutting technology, which not only enhances cutting accuracy but also minimizes material waste.

Moreover, today's stack paper cutters often incorporate smart sensors and AI-driven software, allowing for real-time adjustments based on paper thickness and other material properties. A study published in the Journal of Printing Science and Technology highlighted that such technologies can improve cutting precision by up to 30%, thereby reducing errors and the need for reprints. As the printing industry continues to evolve, the adoption of these innovative cutting solutions will undoubtedly play a crucial role in optimizing workflow efficiency and ensuring high-quality production outcomes.

Cost-Effectiveness of Using Stack Paper Cutters in High-Volume Printing

In high-volume printing environments, cost-effectiveness is a critical factor that can significantly impact overall profitability. Stack paper cutters provide a streamlined solution for cutting large quantities of paper swiftly and accurately, which translates to reduced man-hours and operational expenses. By enabling printers to handle multiple sheets at once, these machines minimize the time spent on repetitive cutting tasks. This efficiency not only cuts labor costs but also allows for faster project completion, giving businesses a competitive edge in the market.

Moreover, the initial investment in stack paper cutters can be quickly recouped through savings on labor and increased productivity. Unlike traditional cutters, which may require significant manual intervention, stack paper cutters automate much of the cutting process, ensuring consistency and precision. This automation reduces material waste due to errors, further enhancing cost-effectiveness. As printing jobs become more complex and demanding, the ability to manage high-volume tasks effectively without compromising quality is paramount, making stack paper cutters an invaluable asset in modern printing workflows.

Integrating Stack Paper Cutters into Digital Printing Systems for Optimal Results

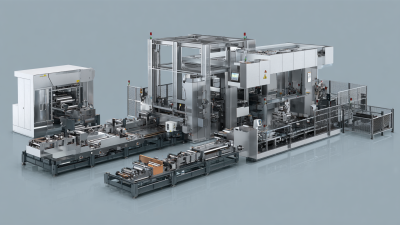

The integration of stack paper cutters into modern digital printing systems is revolutionizing workflows by enhancing efficiency and streamlining production processes. As digital press and printer technologies evolve at an unprecedented pace, integrating these cutters allows for precise and uniform paper cutting, which is essential for achieving high-quality printed materials. By automating the cutting process, businesses can reduce manual labor, minimize errors, and significantly shorten turnaround times.

Furthermore, the use of stack paper cutters in conjunction with advanced digital printing machines enables operators to handle larger workloads while maintaining consistent results. These systems ensure that the final outputs are not only visually appealing but also professionally finished, catering to the increasing demands of customers. As manufacturers continue to introduce innovative printing solutions, the seamless integration of stack paper cutters will play a pivotal role in maximizing productivity and achieving optimal results in modern printing workflows.

Understanding the Benefits of Stack Paper Cutters in Modern Printing Workflows

| Feature | Description | Benefit |

|---|---|---|

| Precision Cutting | Enhances the accuracy of cut sizes | Reduces waste and improves product quality |

| Speed | Cuts multiple stacks of paper at once | Increases overall production efficiency |

| Safety Features | Incorporates guards and automatic shut-off | Minimizes risk of accidents during operation |

| Versatility | Suitable for various paper sizes and types | Adapts to diverse printing needs and projects |

| Integration Capabilities | Compatible with digital and offset printing systems | Streamlines production workflow and logistics |

Maximizing Efficiency in Your Workspace: The Benefits of the GW-S High Speed Paper Cutter

In today’s fast-paced environment, maximizing efficiency in the workspace is crucial for any business aiming to enhance productivity. The GW-S High-Speed Paper Cutter stands out as an exceptional solution, featuring a cutting speed of 48 meters per minute. This remarkable speed ensures that large volumes of paper can be processed swiftly, reducing downtime and allowing for more work to be completed in less time.

Equipped with a 19-inch high-end computer-controlled system, the GW-S cutter offers fully automated operations that simplify the cutting process. The advanced technology not only enhances precision but also minimizes the potential for human error, ensuring each cut meets exact specifications. This level of efficiency made possible by high configuration translates directly into smoother workflows and improved operational output, allowing businesses to meet tight deadlines without sacrificing quality.

Investing in the GW-S High-Speed Paper Cutter means more than just acquiring a tool; it’s about embracing a new standard of productivity. Businesses can enjoy the benefits of increased throughput and streamlined processes, positioning themselves to tackle larger projects effortlessly while maintaining a competitive edge in the industry.

FAQS

: Stack paper cutters are advanced machines designed to handle multiple stacks of paper simultaneously, ensuring uniform cuts and enhancing precision during the print finishing process.

They eliminate inconsistencies associated with manual cutting methods, streamline the finishing process, and enable quicker turnaround times, ultimately improving productivity.

Eureka Machinery, established in 2007, is a leading producer and exporter of printing and packaging machinery, recognized for innovative contributions that empower printing businesses across 88 countries.

Automation in stack paper cutters increases throughput and minimizes the risk of human error, ensuring that each cut is clean and precise, reflecting a growing demand for automated cutting equipment.

Yes, modern stack paper cutters are designed to effectively handle various paper sizes and types, often featuring adjustable cutting blades and programmable settings.

A study indicated that 85% of print service providers reported improved workflow efficiency when utilizing versatile cutting tools like stack paper cutters.

Adaptability allows printers to quickly switch between jobs and types of materials, which significantly enhances productivity and customer satisfaction in fast-paced printing environments.

By ensuring precise finishing that eliminates inconsistencies, stack paper cutters solidify the value of high-quality print results in the production process.

The global demand for automated cutting equipment is expected to grow by 5.2% annually through 2025, highlighting a trend towards automation in printing.

Stack paper cutters offer enhanced precision, reduce the likelihood of human error, and improve efficiency, leading to a higher quality of finished print products.

Conclusion

Stack Paper Cutters play a crucial role in modern printing workflows by significantly enhancing efficiency and precision. Their key features, such as automated cutting and adjustable settings, streamline the trimming process compared to traditional methods, saving time and reducing the potential for errors. Innovations in technology have further improved the precision of cuts, making these cutters ideal for high-volume printing operations.

Moreover, integrating Stack Paper Cutters into digital printing systems leads to optimal results and supports cost-effectiveness in production. Companies like SHANGHAI EUREKA MACHINERY IMP. & EXP. CO., LTD offer advanced solutions in this domain, ensuring that businesses across Europe, Asia, and Africa can maximize their operational efficiency through superior printing and packaging machinery.

Related Posts

-

Exploring Market Trends in Die Cutting Machine For Paper at 2025 China Import and Export Fair

-

Mastering Precision: How to Choose the Perfect Paper Cutter for Your Crafting Projects

-

Maximize Precision: The Ultimate Guide to Choosing Your Perfect Paper Trimmer Machine

-

Revolutionizing Production: The Future of Eco-Friendly Cups Making Machines

-

How to Efficiently Operate a Binding Wire Machine for Maximum Productivity

-

5 Essential Tips for Selecting the Right Automatic Stamping Machine

Blog Tags: