What is an Automatic Cardboard Box Making Machine and How Does It Revolutionize Packaging?

Table of Contents

- Understanding the Basics of Automatic Cardboard Box Making Machines

- Key Features of Automatic Cardboard Box Making Technology

- The Advantages of Using Automatic Machines in Packaging Production

- How Automatic Cardboard Box Machines Improve Efficiency and Reduce Costs

- Innovations in Design: Customization Options Offered by Automatic Machines

- Real-World Applications: Industries Transforming Packaging with Automation

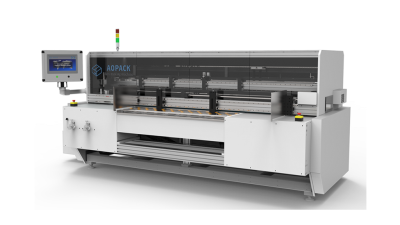

- Innovative and Efficient Packaging Solutions: How the BM2508-Plus Box Making Machine Transforms Your Production Process

- FAQS

- Conclusion

- Related Posts

The packaging world is going through some pretty exciting changes, mainly thanks to new tech—especially with the emergence of the Automatic Cardboard Box Making Machine. I came across this recent report from Research and Markets, and it predicts that the global market for cardboard boxes will hit around $120 billion by 2027. That’s mainly because people are really craving more eco-friendly packaging options, plus e-commerce keeps booming. What’s cool about these machines is how much they speed things up—helping manufacturers churn out high-quality boxes faster, all while cutting down labor costs. A name that’s been leading the charge in printing and packaging machinery is SHANGHAI EUREKA MACHINERY IMP. & EXP. CO., LTD.—they’ve been pushing the boundaries since 2007 and now serve over 88 countries around the world. Basically, this automatic machine isn’t just about efficiency; it’s also a big step toward smarter, greener packaging.

It’s clear that automation and sustainability are shaping where the industry’s headed—and this machine is a prime example of that shift.

Understanding the Basics of Automatic Cardboard Box Making Machines

Automatic cardboard box making machines? They've really changed the game in the packaging world. It’s like, everything's just gotten way more efficient—no more tedious hand-assembly, and companies save a ton on labor costs.

Honestly, industry reports are saying the market for these machines is expected to grow about 5.8% each year between 2021 and 2026. That just shows how much everyone’s leaning into automation these days, right?

Eureka Machinery, which has been around since 2007, is definitely leading the charge here. They’ve got some pretty impressive machines that are known for being precise and reliable. The coolest part? They’re all over the place—serving clients in 88 countries across Europe, Asia, Africa, you name it. They really focus on giving their customers top-notch technology that fits all kinds of packaging needs. These automatic machines don't just speed things up—they also help keep the quality high, which is super important when you're in a competitive market. As more businesses aim to streamline their supply chains, I think machines like these will be a total game changer for future packaging strategies.

Key Features of Automatic Cardboard Box Making Technology

These days, automatic cardboard box making machines are really shaking up the packaging world — they bring a lot of efficiency and fresh ideas to the table. Basically, they do the heavy lifting when it comes to producing boxes, cutting and folding with pretty much perfect precision. It’s a game-changer because it cuts down on the manual labor and sharply reduces mistakes. And what’s cool is, they can handle all kinds of box sizes and styles — whether it’s just a simple shipping box or something more complex and customized. That kind of flexibility means businesses can really roll with the punches and respond quickly to what the market needs.

If you’re thinking about investing in one, it’s worth considering how it can boost your overall production. Just don’t forget—regular upkeep and making sure your team knows how to operate it properly will go a long way in getting the most out of your machine. Oh, and if you can find a model that supports digital printing, that’s even better — it’ll make customizing your packaging a lot quicker and easier, especially when you need branded boxes in a rush.

Another thing to keep in mind is whether the machine works well with different types of cardboard. Versatility here is key because it lets you serve a broader range of clients. Also, take a look at how fast it can produce and how much output it can handle — that way, you won’t sacrifice quality just to meet your deadlines. By paying attention to these features, your business can stay competitive and stay ahead of what your customers are looking for.

The Advantages of Using Automatic Machines in Packaging Production

Automatic cardboard box making machines are really changing the game in the packaging world. Honestly, their benefits are pretty impressive, especially when it comes to modern manufacturing. These machines help streamline the whole process, so things move faster and more efficiently. Instead of relying on a lot of manual labor, automating the box creation not only cuts down on costs but also reduces mistakes—meaning you get more consistent quality every time. Plus, these machines can work way quicker than people, which is a big help when demand is skyrocketing and time is tight.

And if you look at the bigger picture, this move towards automated packaging is totally in line with current trends. The market’s craving for more advanced, reliable equipment is huge right now. Companies are on the lookout for vendors who can deliver machines that last, are precise, and fit their unique needs. As we all try to be more efficient and cut down on waste, the upside of these automatic machines becomes pretty obvious. Not only do they boost productivity, but they also support sustainability goals by reducing material waste and managing resources better. Investing in these automatic box makers is really about staying competitive and flexible in an ever-changing market—it’s a smart move for sure.

How Automatic Cardboard Box Machines Improve Efficiency and Reduce Costs

Automatic cardboard box making machines are really changing the game for the packaging world. They help streamline the whole process and cut down on labor costs — it's like having a reliable team that works faster and more efficiently. These machines can quickly produce boxes in all sorts of sizes and shapes, which means less manual work and faster turnaround times. Honestly, as businesses are demanding quicker deliveries these days, having tools like these becomes pretty much a game-changer.

To get the most out of these machines, it’s super important to keep up with regular maintenance. Things like lubricating the moving parts and making sure the blades stay sharp can really improve performance and help the machine last longer. And don’t forget, training staff on how to operate these machines efficiently can make a big difference — it’s all about squeezing every bit of capability out of them.

Another big perk? Cost savings. With automatic box makers, you rely less on manual labor, which seriously lowers operational costs. Plus, their precise cutting and folding reduce material waste — definitely a smart move when you’re trying to keep costs down. It’s also helpful to keep an eye on your stock levels, so you’re using the most economical materials without sacrificing quality. All in all, these machines are not just a cool tech upgrade; they really help boost productivity and save money in the long run.

Innovations in Design: Customization Options Offered by Automatic Machines

Automatic cardboard box making machines are really shaking up the packaging world. They offer so many customization options that businesses of all kinds can find something that suits their needs perfectly. These high-tech machines make it simple to design and produce boxes in all sorts of shapes and sizes, giving companies the chance to create packaging that really reflects their brand. With features like adjustable dimensions and personalized print options, it’s easy to tweak designs to fit everything from protecting products to catching the eye with a cool look.

What’s pretty neat is how these machines aren’t just about making boxes of different sizes — they come with user-friendly controls that let operators punch in custom specs without a hassle. Plus, many models can quickly generate all kinds of box styles, like corrugated, foldable, or rigid ones, which helps cut down on production time big time. This means businesses can respond faster to market changes and customer preferences, making operations smoother and giving customers a more engaging experience overall.

Automatic Cardboard Box Making Machine: Innovations in Design

This chart illustrates key performance metrics of Automatic Cardboard Box Making Machines, highlighting innovation in customization options, efficiency in production speed, material waste reduction, and energy consumption, thereby showcasing how these machines are revolutionizing the packaging industry.

Real-World Applications: Industries Transforming Packaging with Automation

Automatic cardboard box-making machines are really changing the game when it comes to packaging across different industries. Thanks to recent advances in automation tech, these machines are not only speeding up production but also helping cut down labor costs. Because of that, they’ve become pretty much a must-have for businesses wanting to streamline their operations. I came across a report from Smithers Pira that says the global market for packaging automation is expected to hit around $80 billion by 2024 — pretty impressive, right? It just shows how more companies are jumping on the automated packaging bandwagon.

Innovative and Efficient Packaging Solutions: How the BM2508-Plus Box Making Machine Transforms Your Production Process

The BM2508-Plus Box Making Machine represents a significant advancement in packaging technology, specifically designed to enhance production efficiency and innovation. With the capability to work with corrugated board types—single and double wall—this machine caters to diverse packaging needs. It can handle cardboard thicknesses ranging from 2mm to 10mm, accommodating a broad density spectrum of up to 1200g/m². This versatility ensures that businesses can create packaging that meets specific requirements, from lightweight containers to robust boxes for heavy products.

One of the standout features of the BM2508-Plus is its adaptability in board size. It can process boards with a maximum width of 2500mm and an unlimited length, as well as a minimum size of 200mm width and 650mm length. This flexibility allows manufacturers to produce a wide array of box sizes and styles, catering to different market demands while maximizing operational efficiency. With a production capacity ranging from approximately 400 to 600 pieces per hour, the machine significantly streamlines the production process, enabling companies to meet high-volume orders without compromising quality.

FAQS

: Automatic cardboard box making machines are innovative tools that automate the entire process of box production, enhancing efficiency and reducing labor costs in the packaging industry.

The packaging machinery market is expected to grow at a CAGR of 5.8% from 2021 to 2026, indicating a rising demand for automated solutions that improve packaging processes.

These machines allow businesses to create boxes in various shapes and sizes with adjustable dimensions and customizable print options, enhancing brand identity and meeting specific product needs.

Industries such as e-commerce, food and beverage, and electronics rapidly adopt these machines to improve production efficiency and meet growing packaging demands.

They streamline production cycles, allow for quick adjustments in box design, and enable businesses to respond swiftly to market trends and customer demands.

Established in 2007, Eureka Machinery offers advanced machines recognized for their precision and reliability, supporting clients in 88 countries in enhancing their packaging processes.

The global packaging automation market is expected to reach $80 billion by 2024, reflecting the trend towards automated packaging solutions in various industries.

By optimizing productivity and reducing waste, the integration of automatic machines leads to significant improvements in sustainability within the packaging sector.

Enhanced automation reduces lead times, increases operational efficiency, and allows for the production of unique box styles easily, benefiting businesses in a competitive market.

Yes, many models incorporate user-friendly interfaces that enable operators to seamlessly input unique specifications for customized box designs.

Conclusion

The Automatic Cardboard Box Making Machine is really a game-changer in the packaging world. It offers a neat, hassle-free way to produce cardboard boxes quickly and without breaking the bank. If you get a chance to understand how it works, you'll see how it combines robotics with precise engineering — it’s pretty impressive how it boosts both speed and consistency. What really makes this machine stand out are features like customizable designs and automation, which don’t just save time but also cut down on costs. That makes it a must-have for manufacturers trying to stay ahead.

Eureka Machinery, which’s been around since 2007, is a big player in this tech wave. They’re providing some of the most advanced automatic machines that serve a wide range of industries across 88 countries. The fact that you can tweak the box designs to suit your needs just shows how flexible this machine is — perfect for businesses looking to meet specific market demands and stay competitive. As more industries jump into automation, this tech is really changing the game in packaging and opening doors to even more innovations down the line.

Blog Tags: