What is an Automatic Baler and How Does it Work for Efficient Waste Management

Table of Contents

- What is an Automatic Baler in Waste Management?

- The Importance of Efficient Waste Management Solutions

- How Automatic Balers Operate: A Step-by-Step Guide

- Key Components of an Automatic Baler Explained

- Advantages of Using Automatic Balers for Waste Reduction

- Applications of Automatic Balers in Various Industries

- Maintenance and Safety Tips for Automatic Balers

- Maximizing Efficiency with the Horizontal Semi-automatic Baler: Features, Benefits, and Applications of the JPW60BL

- FAQS

- Conclusion

- Related Posts

Hey, have you noticed how fast the world of waste management is changing these days? It’s pretty clear that coming up with innovative solutions is more important than ever. One device that’s been catching a lot of attention lately is the Automatic Baler. Honestly, it’s a pretty impressive piece of machinery that helps sort out waste more efficiently. It takes loose recyclables and compresses them into neat, tight bales—making them much easier to handle and ship off. The cool part? By automating this process, companies can save a ton on labor costs and get their operations running smoother. That’s why the Automatic Baler has really become a must-have in modern recycling setups and waste management systems.

But if you really want to get why this thing matters, you gotta understand how it works. Basically, these machines intake loose recyclable stuff, squash it down, and turn it into uniform bales. It’s like a giant, efficient wrapping machine. Not only does this make things simpler and faster, but it also means less space taken up by waste—an absolute win. Plus, on a bigger scale, these balers can help us all be a little greener by encouraging recycling of materials that would otherwise just pile up in landfills. So, if you're serious about improving how you handle waste and caring about the environment, taking a closer look at Automatic Balers might just be a smart move.

What is an Automatic Baler in Waste Management?

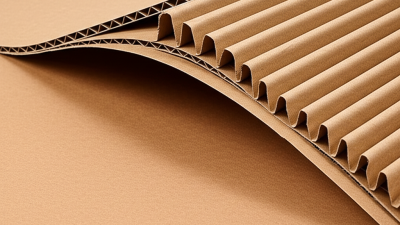

An automatic baler is an essential piece of equipment in waste management, designed to efficiently compress various types of waste materials into compact bales. This machine automates the process of sorting, compressing, and tying waste, significantly reducing the volume of materials and making them easier to handle, transport, and recycle. Automatic balers can handle a diverse range of materials, including cardboard, plastic, and paper, helping facilities streamline their waste management processes by minimizing manual labor and increasing productivity.

The operation of an automatic baler is relatively straightforward yet highly effective. Waste materials are fed into a hopper where they are automatically collected and compacted by powerful hydraulic systems. Once the material reaches a designated density, the baler binds it using twine or wire and ejects the completed bales for storage or transport. This automated approach not only improves efficiency but also ensures a safer working environment by reducing worker exposure to heavy lifting and potentially hazardous waste materials. Through the use of automatic balers, organizations can bolster their waste management strategies and contribute to sustainable recycling efforts.

The Importance of Efficient Waste Management Solutions

Efficient waste management is crucial for sustainable development and environmental protection. According to a recent report by the World Economic Forum, approximately 2.01 billion tons of waste is generated globally each year, with at least 33% not managed in an environmentally safe manner. This staggering figure highlights the pressing need for advanced waste management solutions that can handle the increasing volume of waste effectively. Automatic balers play a significant role in addressing these challenges by compacting waste materials into manageable bales, facilitating easier storage and transportation while minimizing the area required for waste.

The adoption of automatic balers contributes to waste management efficiency by reducing the volume of recyclable materials, which can lead to significant cost savings. The Business Research Company estimates that the global baler market is projected to grow to $1.57 billion by 2027, reflecting an increasing recognition of the need for innovative waste processing technologies. By improving operational efficiency and reducing labor costs, businesses can not only enhance their waste management strategies but also contribute to a circular economy, promoting resource recovery and sustainability. Efficient waste management solutions, including automatic balers, are therefore essential in our collective effort to reduce waste output and mitigate environmental impact.

Waste Management Efficiency: A Comparison of Different Solutions

This bar chart illustrates the efficiency of various waste management solutions, measured in units processed per hour. The Automatic Baler stands out as the most efficient option, significantly outperforming manual alternatives and other methods.

How Automatic Balers Operate: A Step-by-Step Guide

Automatic balers are essential machines used in waste management processes, designed to optimize the handling and recycling of materials. The operation of an automatic baler can be broken down into several key steps, enhancing its efficiency and effectiveness. Initially, waste materials, such as cardboard or plastics, are fed into the machine. An automatic feeding mechanism ensures a consistent flow, which is vital for maintaining high throughput.

Once the materials are inside the baler, the system engages cutting and crushing components that compact the waste. This stage reduces the volume of the materials significantly, making handling and transportation easier. Following compaction, the baler uses a series of hydraulic systems to bind the compressed waste into bales, utilizing wire or twine to secure each bundle.

The process culminates in the automatic discharge of finished bales, ready for storage or shipment to recycling facilities. This step-by-step operation not only streamlines waste management but also optimizes recycling efforts, making it a crucial component in modern sustainability practices.

Key Components of an Automatic Baler Explained

An automatic baler is a crucial piece of equipment in waste management, designed to compress waste materials into compact bales for easier handling, storage, and transportation. The key components of an automatic baler include the feeding mechanism, compaction chamber, binding system, and control panel. Each of these components plays a vital role in ensuring the efficient operation of the baler.

The feeding mechanism is responsible for transporting waste materials into the compaction chamber. This can involve conveyor belts or other systems that help in directing the flow of materials into the baler. Once in the compaction chamber, the waste is subjected to powerful hydraulic pressure that compresses it into dense bales. This reduction in volume not only optimizes storage space but also lowers transportation costs.

After the compaction process, the binding system securely fastens the bales, typically using wire, twine, or strapping materials. This ensures that the bales maintain their shape during handling and transport. The control panel, often featuring user-friendly interfaces, allows operators to monitor the machine’s status, adjust settings, and ensure safe operation. Together, these components make automatic balers an integral part of modern waste management solutions.

Advantages of Using Automatic Balers for Waste Reduction

Automatic balers are increasingly becoming a crucial asset in the realm of waste management, providing numerous advantages that significantly contribute to waste reduction. These machines are designed to compress and bundle waste materials into compact bales, optimizing storage and transportation efficiency. According to a report by the Waste Business Journal, the utilization of balers can reduce waste volume by up to 90%, effectively minimizing the space required for waste storage and lowering disposal costs for businesses.

Moreover, automatic balers enhance recycling processes. By consolidating recyclables, such as cardboard and plastics, these machines make it easier for waste management facilities to handle materials. A study conducted by the EPA indicates that mechanical compaction can lead to a 30% increase in recovery rates for recyclables, thereby promoting a circular economy. Additionally, balers reduce labor costs associated with manual sorting and handling, as automated systems require less workforce engagement. This not only streamlines operations but also lessens the potential for workplace injuries, aligning with safety standards in waste management practices. As organizations seek to improve their sustainability efforts, investing in automatic balers presents a practical solution for effective waste reduction and enhanced operational efficiency.

Applications of Automatic Balers in Various Industries

Automatic balers play a crucial role in waste management across various industries by streamlining the process of compacting recyclable materials. In sectors such as retail, manufacturing, and food service, automatic balers efficiently process large volumes of waste, transforming it into easily manageable bales.

According to a report by the Environmental Protection Agency (EPA), recycling rates can increase by 30-50% when using balers, as they make the handling and transport of recyclable materials more economical. This enhancement in efficiency not only reduces waste sent to landfills but also supports companies in achieving their sustainability goals.

In manufacturing, for example, automatic balers are employed to handle a range of materials, including cardboard, plastics, and metals. The American Recycling Association estimates that proper baling can reduce material volume by up to 90%, which is significant for operations looking to optimize space and costs. In the food service industry, automatic balers manage waste from packaging materials and leftover food, helping to minimize the environmental impact while maintaining compliance with local waste management regulations. As industries continue to seek innovative solutions for waste reduction, the utilization of automatic balers will remain vital in promoting recycling and sustainability initiatives.

Maintenance and Safety Tips for Automatic Balers

When operating an automatic baler, regular maintenance is crucial to ensure its longevity and efficiency. Operators should establish a routine inspection schedule that includes checking the hydraulic system for leaks, examining the belts and rollers for wear, and ensuring that all electrical connections are secure. Cleaning the baler regularly, especially around the knife and feeding areas, helps to prevent material buildup that can lead to jams, reducing downtime and prolonging the machine’s life. Additionally, replacing worn or damaged components promptly can avoid more significant issues in the future.

Safety is another critical aspect of operating an automatic baler. Operators should always be trained in the proper use of the machine, including understanding emergency stop functions. Personal protective equipment (PPE) such as gloves, safety glasses, and steel-toed boots should be worn at all times. It's essential to keep the area around the baler clear of obstacles and to never reach into the machine while it is operating. Regularly updating the team on safety protocols and conducting audits can enhance the safety culture and ensure that everyone is aware of potential hazards.

What is an Automatic Baler and How Does it Work for Efficient Waste Management - Maintenance and Safety Tips for Automatic Balers

| Baler Type | Capacity (Tons/hour) | Power Consumption (kW) | Main Features | Maintenance Frequency (Months) | Safety Measures |

|---|---|---|---|---|---|

| Horizontal Baler | 15 | 22 | Automated tying, energy-efficient design | 6 | Emergency stop buttons, safety interlocks |

| Vertical Baler | 5 | 7.5 | Space-saving design, ease of use | 4 | Personal protective equipment (PPE), training |

| Auto-tie Baler | 10 | 12 | Automatic binding system, high throughput | 8 | Regular safety audits, proper training |

Maximizing Efficiency with the Horizontal Semi-automatic Baler: Features, Benefits, and Applications of the JPW60BL

The Horizontal Semi-automatic Baler, specifically the JPW60BL model, is designed to enhance efficiency in waste management processes. Utilizing 60 tons of hydraulic power, this baler is capable of compacting various materials into manageable bales, significantly reducing waste volume and improving storage logistics. The machine operates effectively with a bale size dimension of 750*850*(300-1100)mm, accommodating a range of materials and sizes to meet diverse operational needs.

With a feed opening size of 1200*750mm, the JPW60BL allows for easy loading of materials, minimizing downtime and maximizing productivity. Its capability to produce 3-5 bales per hour ensures that operations can maintain a steady workflow, meeting high demands without compromising on quality. Each bale can weigh between 200-500kg, making this baler ideal for industries that require efficient recycling or waste management solutions. The combination of these features not only streamlines operations but also supports sustainability efforts by enabling efficient material processing.

FAQS

: An automatic baler is a machine used to compress various types of waste materials into compact bales, automating the sorting, compressing, and tying processes to reduce volume and improve efficiency in waste handling.

The operation involves feeding waste materials into a hopper, where they are compacted by hydraulic systems. Once compressed, the baler binds the materials using twine or wire and ejects the finished bales for storage or transport.

Automatic balers can process a variety of materials, including cardboard, plastic, and paper, making them suitable for different waste management needs across various industries.

Benefits include reduced manual labor, increased productivity, enhanced efficiency in recycling processes, and a safer working environment by minimizing worker exposure to heavy lifting.

Automatic balers are widely used in sectors such as retail, manufacturing, and food service, where they help manage large volumes of waste and improve recycling rates.

By efficiently compacting recyclable materials, automatic balers can increase recycling rates by 30-50%, reduce landfill waste, and support organizational sustainability goals.

Conclusion

An Automatic Baler is a crucial machinery in waste management, designed to efficiently compress and bundle waste materials for easier handling and transportation. Its operation involves a series of steps where waste is fed into the machine, compacted, and then tied into bales, reducing the volume of waste significantly. The importance of efficient waste management solutions cannot be overstated, as it helps minimize landfill usage and promotes recycling.

The structure of an Automatic Baler includes key components such as a feeding system, compressing chamber, and tying mechanism, all working in harmony to streamline waste processing. The benefits of using Automatic Balers extend across various industries, enabling waste reduction and enhancing recycling efforts. Regular maintenance and adherence to safety protocols are essential for the optimal performance of these machines, ensuring they operate efficiently while safeguarding workers and the environment.

Related Posts

-

2025 How to Choose the Best Cardboard Core Cutter for Your Needs

-

Mastering Precision: Top Paper Cutters for Perfect DIY Craft Projects Every Time

-

Exploring Options for the Viena Seja Gofrētā Kartona Mašīna in Packaging Solutions

-

Revolutionizing Packaging Efficiency: The Ultimate Guide to Folder Gluer Machines

-

Exploring Competitive Edge: Cutter Price Insights at the 138th Canton Fair 2025

-

7 Reasons Why the Ultimate Bag Making Machine is a Game Changer for Your Business

Blog Tags: