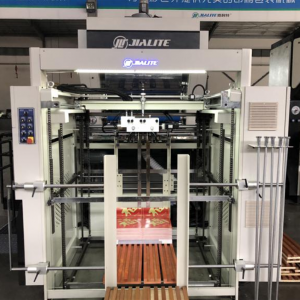

Umshini Wokugqwala Oqondile Ozenzakalelayo we-NFM-H1080

| Imodeli | I-FM-H |

| I-FM-1080-Ubukhulu bephepha - mm | 1080×1100 |

| I-FM-108Usayizi wephepha ongu-0-mm | 360×290 |

| Isivinini-m/min | 10-90 |

| Ubukhulu bephepha-g/m2 (ukunqunywa kommese oyindilinga) | 80-500 |

| Ubukhulu bephepha-g/m2 (ukusika ummese oshisayo) | ≥115gms |

| Ukugqagqana ngokunemba-mm | ≤±2 |

| Ubukhulu befilimu (i-micrometer evamile) | 10/12/15 |

| Ubukhulu beglue evamile-g/m2 | 4-10 |

| Ubukhulu befilimu yokunamathisela kusengaphambili-g/m2 | 1005,1006,1206 |

| Ukondla Okungayeki Ukuphakama-mm | 1150 |

| Ukuphakama kwephepha lomqoqi (kufaka phakathi i-pallet) -mm | 1050 |

| Pamandla | 380V-50Hz-3Pamandla okushisa:20kWamandla okusebenza:35-45KwAmandla aphelele ami eduze:75Kw I-circuit breaker: 160A |

| wingcindezi yokusebenza-i-Mpa | 15 |

| Iphampu yokuhlanza | 80i-psiAmandla: 3kw |

| I-Air compressor | Ukugeleza kwevolumu: 1.0m3/min,Ingcindezi elinganisiwe: 0.8mpaAmandla: 5.5kwIpayipi lokungenisaUDia.8mm (phakamisa ukuthi usebenzise umthombo womoya ophakathi) |

| Ubukhulu bekhebula-mm2 | 25 |

| Isisindo | 9800kgs |

| Ubukhulu (isakhiwo) | 8400*2630*3000mm |

| Iyalayisha | 40HQ |

IYUNITHI YOKUDLA

1. I-Servo Motor feeder, ama-sucker ama-4 okuphakamisa kanye nama-sucker ama-4 okwakha ukuthutha. Isivinini Esiphezulu Amashidi angu-12000/h.

2. Ithebula lokudla iphepha linokuvikelwa okungaphezu komkhawulo okuphezulu nokuphansi.

3. Ukuphakama kokudla okungami kungafinyelela ku-1150mm, idivayisi yokubeka kusengaphambili, ukudla okungami.

4. Ukulungiswa okuhlakaniphile kwezikhundla zangaphambili nangemuva ze-Feeder, faka nje idatha yomkhiqizo kuphaneli yokulawula

5. Iphampu ye-VACUUM ye-BECKER

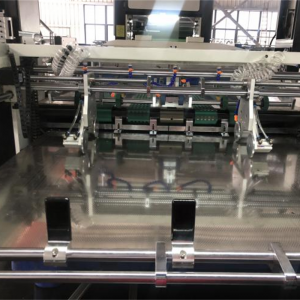

ITHEBULA LOKUDLULISA NOKUDLANA

1. Ithebula lokudlulisa lisebenzisa ibhodi elenziwe ngensimbi engagqwali elenziwe ngokwezifiso.

2. Isondo lebhulashi kanye nesondo lokucindezela irabha kuhamba kahle.

3. Ukugqagqana kwenjini ye-Servo, kuthuthukisa ukunemba kwe-lap, iphutha≤±2mm.

ISIKHUPHULELO SOKUTHUTHA NOKULAMULA KWAMAFASIRISI (OKUNGAKHETHWA) Isikhiphi se-Powder esisusa i-Powder i-window coater kanye ne-dryer

Idivayisi yokususa i-powder roller eyodwa yokushisa (ongakukhetha) inesakhiwo esincane, ipulatifomu inomsebenzi wokumunca ukuqinisekisa ukuthi iphepha lidlula kudivayisi yokususa i-powder alishintshi.

Umshini wokususa uthuli ungasusa uthuli ebusweni bephepha ngemva kokuphrinta ukuze ugweme amabala amhlophe ngemva kokuba iphepha selimboziwe.

Ngokuya ngesidingo samakhasimende, faka idivayisi ye-inkjet etafuleni lokususa uthuli, i-inkjet kanye nomshini wokulaminata.

Ithebula le-inkjet lingakhethwa ngokuzimela.

Ukwembozwa kwefasitela (ongakukhetha), okwakhiwa ngekhanda lomshini wokunamathisela kanye ne-oven ye-infrared. Ngemva kokuba iphepha linamathiselwe, lihlanganiswa nefilimu ngemva kokudlula kuhhavini we-infrared.

Iyunithi yokomisa enokukhanya kwe-IR okungu-12, Amandla okushisa aphelele angu-14.4kw.

Uma ungasebenzisi imikhiqizo yamafasitela, le ngxenye ingasetshenziswa njengedivayisi yokususa impuphu yamanzi.

UMHOLI WE-LAMINATOR

Ububanzi be-roller yokomisa bukhuphuke baba ngu-1000mm, kusetshenziswa uhlelo lokushisa olusebenzisa ugesi.

I-heating press roller isebenzisa uhlelo lokushisa oluhlukaniswe ngezigaba, olusebenza kahle futhi olusindisa amandla.

Ukucindezela okuphezulu kwe-press roller kungu-12T.

I-glue roller kanye ne-metering roller ziqhutshwa yizinjini ezizimele ezimbili, okwenza ukulungiswa kube lula kakhulu.

Ukwelashwa kwenqubo ye-Teflon yohlelo lokunamathisela, kulula ukuyihlanza futhi ayinamatheli.

Idivayisi yokugoqa ifilimu yemfucuza.

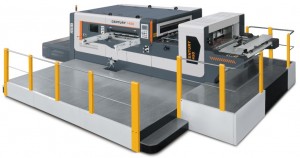

IYUNITHI YOKUSIKA

Umsiki wephepha ufakwe isilawuli sokucindezela kanye nedivayisi yokulwa nokugoba ukuqinisekisa ukuthi iphepha liyisicaba futhi aligobile.

Ingxenye yokusika iphepha iqukethe isondo lokugaya, ummese wediski kanye nommese oshisayo wokusika, okuhlangabezana nezidingo zamakhasimende zokusika amafilimu ngezinto ezahlukene.

I-bounce roller ilawulwa yinjini ezimele, futhi iphepha lingahlukaniswa ngokusebenzisa umehluko wesivinini.

Ummese oshisayo osebenzisa ukucindezela okuphansi kokushisa nokusika ngqo ngaphandle kwefilimu yomsila, ukuthola ukujiya kwephepha nokusika, okunembile futhi okusebenzayo.

UMQOQI ONGAPHELI

Ukuphakama komqoqi ongami kungafinyelela ku-1050mm. Uma isitaki sesicishe sigcwele, ibhande lokuhambisa elizodiliva lizonwebeka ngokuzenzakalelayo ukuze lamukele iphepha. Ipulatifomu yomqoqi izowa. Ngemva kokuba ithileyi selishintshiwe, ipulatifomu izophinde isebenzise futhi iqedele umqoqi ongami.

Sebenzisa isakhiwo sokuhlunga iphepha elinomoya ukuqinisekisa ukuhlanzeka kwephepha futhi wenze lula inqubo elandelayo, ngesondo lokunciphisa ukuvimbela iphepha ukuthi lonakale ngenxa yokushaya ngokushesha kakhulu endaweni ephazamisayo.

Uma kubalwa iso likagesi, inani lephepha elisebenzayo liboniswa esikrinini sokubonisa emshinini wokuthatha, elingasuswa futhi liqongelelwe.

Iso likagesi lokungenisa, lizwa ubude bephepha, uma ubude bephepha bushintsha, ibhande lizoshesha, futhi ukuphazamiseka komshini wokuthwala kuzogumbuqela futhi kuphakamise iphepha.

Umphakamisi wefilimu

Izingxenye ezisele