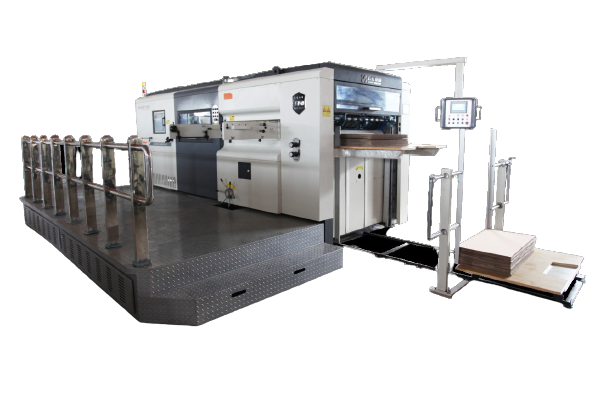

I-Century MWB 1450Q (ene-stripping) I-Semi-Auto Flatbed Die Cutter

| Imodeli | MWB1450Q |

| Usayizi Wephepha Ophezulu | 1480*1080 mm |

| Usayizi Wephepha Omncane | 550*480 mm |

| Usayizi Wokusika Omkhulu | 1450*1050 mm |

| Ukucindezela Okuphezulu Kokusika | 300x104N |

| Ububanzi Besitoko | Ibhodi elinothayela ≤ 9 mm |

| Ukunemba Kokusika Nge-Die | ±0.5 mm |

| Isivinini Esiphezulu Somshini | 4000s/h |

| Ukulungiswa kwengcindezi | ±1 mm |

| Umkhawulo Ongaphambili Omncane | 8MM |

| Usayizi Wokushayisa Kwangaphakathi | 1480*1080 mm |

| Amandla Aphelele | 21KW (ngaphandle kwepulatifomu yokusebenza |

| Ubukhulu Bomshini | 7750*4860*2440 mm (Faka ipulatifomu yokusebenza, i-pre-feeder) MWB1620Q |

| Ubukhulu Bomshini | 5140*2605*2240 mm (Khipha ipulatifomu yokusebenza, i-pre-feeder) MWB1620Q |

| Isisindo Esiphelele | 19t |

Isigaba Sokudla

√Uhlelo lokudla olusebenzayo ngesandla.

√Uhlelo lokuphakamisa inqwaba yamashidi ngokuzenzakalelayo.

√Umhlahlandlela oseceleni wokubeka inqwaba yephepha phakathi nendawo.

√Kusebenza ku-E, B, C, A flute kanye nodonga oluphindwe kabili.

Isigaba Sokusika Ngokufa

√Indlela yokukhiya i-die-chase ngenkinobho yokucindezela yomoya ukuqinisekisa ukuthi ukushintsha ipuleti lokusika i-die kuphephile futhi kulula kubasebenzisi.

√Uhlelo lomugqa ophakathi nendawo lokusetha nokushintsha idayisi ngokushesha.

√Uhlelo lwe-Knuckle lokucindezela okukhulu kokusika kufika kumathani angu-400

√Uhlelo lokuzigcoba oluzenzakalelayo noluzimele ukuze lusebenze kahle futhi luphile isikhathi eside

√Umnyango wokuphepha kanye nedivayisi kagesi ethatha izithombe ukuze kusetshenziswe ngokuphephile.

Isigaba Sokuhlubula

√Uhlaka olungaphezulu lokukhumula lungaphakanyiswa ukuze kukhumulwe ukufakwa nokushintsha kwedayi.

√Uhlelo lwe-Centerline lokususa ngokushesha i-die setting kanye nokushintsha umsebenzi

√Idivayisi yokukhiya uhlaka, iguquguquka futhi kulula ukuyikhiya nokuyikhulula idayisi yokukhumula.

√Isensa yesithombe kanye nefasitela lokuphepha elihlonyiselwe ukusebenza ngokuphephile.

√Uhlelo lokukhumula kancane lushiya unqenqema lwesibambi lungakhumuliwe.

Isigaba Sokulethwa

√Ama-jogger aseceleni nangaphambili ukuqinisekisa ukuthi i-stacking ihlelekile.

√Uhlelo lokulethwa kwephalethi

√Idivayisi yokuhlola ye-photoelectric yokungena nokusebenza ngokuphepha.

Isigaba Sokulawula Ugesi

√Ubuchwepheshe be-Siemens PLC ukuqinisekisa ukusebenza okungenazinkinga.

√Izingxenye zikagesi zivela kwa-Siemens, Schneider.

√Zonke izingxenye zikagesi zihlangabezana nezindinganiso ze-CE

| Igama lengxenye | Umkhiqizo |

| Ukuthwala okuyinhloko | I-NSK |

| Iketanga elikhulu lokushayela | I-RENOLD |

| I-Vacation Inverter | YASKAWA |

| Izingxenye Zikagesi | I-Siemens/Schneider |

| I-Encoder | I-OMRON |

| Izinzwa zesithombe | I-Panasonic/Omron |

| Injini eyinhloko | I-Siemens |

| Ingxenye yomoya | I-AirTac/SMC |

| I-PLC | I-Siemens |

| Iphaneli Yokuthinta | I-Siemens |

I-Pre-feeder

Lo mshini wokondla kusengaphambili usiza ukwenza inqwaba yamashidi elandelayo ilungele futhi wenze ukushintsha okusheshayo kwenqwaba yamashidi. Lapho umqhubi epha umshini wokusika amashidi amashidi, omunye umqhubi angalungisa enye inqwaba yamashidi ngesikhathi esifanayo. Uma ukufakwa kweshidi sekuqediwe, inqwaba yamashidi elungiselelwe kumshini wokondla kusengaphambili ingacindezelwa kudivayisi yokuphakamisa inqwaba ngokuzenzakalelayo. Lokhu kuzokonga cishe imizuzu emi-5 yokulungiselela inqwaba yamashidi ngayinye futhi kwandise umkhiqizo.

Iphaneli yokusebenza enengalo enyakaziswayo// Iphaneli Yokuthinta ye-Siemens Smart Line

Isigaba Sokudla

√Ikhamera yokuqapha isimo sokulethwa ngaphakathi kwesigaba

√Uhlelo lokuphakamisa izinqwaba oluzenzakalelayo

√Idivayisi yokulungisa isikhala sokungenisa ukudla phakathi kwamashidi nezibambi.

√Ifasitela lokuphepha kanye nenzwa yesithombe kunikeza isivikelo kumqhubi kanye nomshini uma ifasitela lokuphepha livuliwe.

√Ipuleti lokucindezela ukuqinisekisa ukuthi amashidi awaphakelwa ngokweqile ukuze acinywe

√Abagijimi baseceleni ukuze bagcine inqwaba iphakathi nendawo futhi bathole amashidi angena kalula futhi anembile.

Inzwa yesithombe ukugcina ukuphakamisa inqwaba kusesikhathini njalo sokuphakelwa kwamashidi.

Isigaba Sokusika Ngokufa

√Ipuleti lokusika idayi lenziwe ngama-65Mn anobulukhuni be-HRC45, elifanele ukusika idayi.

√Ifasitela lokuphepha lihlonyiselwe ukuphepha komqhubi kanye nomshini.

√Uhlelo lomugqa ophakathi nendawo lokusika isethi yedayi ngokushesha kanye nokushintsha umsebenzi.

√Isibambo sokulungisa amandla okusika. Kulula futhi kulula.

Isondo lezimpethu elinobuciko bokugaya ngesandla ukuqinisekisa ukuthi indawo ibushelelezi ukuze kusikwe kahle.

Uhlelo lokuzigcoba oluzenzakalelayo

I-Mono-cast yenzelwe ukudlidliza okuncane lapho umshini usebenza.

I-apron yokusekela ingalungiswa ibe ngamasayizi ahlukene ukuze ivumelane nosayizi wamashidi ahlukene.

Isigaba Sokulethwa

√Uhlelo lokulethwa kwephalethi olungami

√Iphaneli yokusebenza

√Ifasitela lokuphepha

√Inzwa yesithombe ifakwe ukuqinisekisa ukuthi umshini uzoma uma okuthile kungena emshinini kulesi sigaba.

√Ama-jogger aseceleni okuqoqa amashidi acocekile

Iwindi lokubuka ukuze kuhlolwe iqoqo lamashidi futhi kwenziwe ukulungiswa okudingekayo uma kudingeka.

Idivayisi yokulungisa ifomethi yeshidi

Ukulawulwa Kukagesi

CPU Module//Siemens Simatic S7-200

I-Yaskawa Frequency Inverter

Ama-relay e-Schneider, ama-contactor njalo njalo.

Ama-gripper bars, enziwe ngezinto ze-aluminum zezindiza.

Kuzothunyelwa amasethi amabili engeziwe e-gripper bar kanye nomshini njengezingxenye ezisele.

-300x179.jpg)

-300x204.jpg)

-300x179.jpg)

-300x200.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)