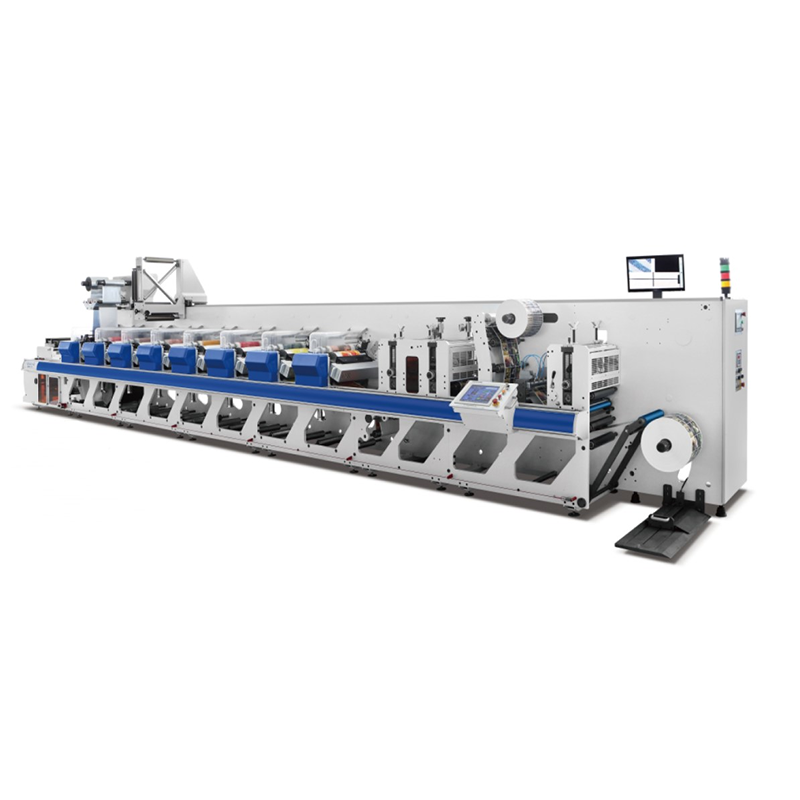

Mochini oa khatiso oa Flexo oa ZJR-450G

BOTŠOARO

1. Mochini oohle o amohela sistimi ea morao-rao ea taolo ea servoSiemensho tsoa Jeremane le khatiso e 'ngoe le e 'ngoe

Yuniti e khannoa ke enjene e ikemetseng ea servo. Ho na le17servodienjene kaofela bakeng sa7'malasmochini o netefatsang hore ngoliso e nepahetseng e sebetsa ka lebelo le phahameng.

2. Rolara ea khatiso e sebelisa sistimi ea matsoho e bobebe, e bonolo, e bonolo le e fetohang ka potlako. Moralo ona o ntlafatsa boleng ba khatiso haholo 'me o fokotsa tlhokomelo.

3. Phetoho e potlakileng le e bonolo ea khatello ea khatiso kapa phetiso ea enke: rolara ea khatiso e tsamaisoang ke mojari. Ha se

ho hlokahala ho lokisa khatello ha o fetola rolara, kapa bonyane ho lokisa hanyane bakeng sa mosebetsi o khethehileng.

4. Anvil roller e hlomelloa ka metsi a pholileng, e loketse thepa ea filimi hape

SETS'OANTŠISO SA LINTHO TSE BONOLO

Pampiri le pampiri e khomaretsang: Ligrama tse 20 ho isa ho tse 500

Bopp, Opp, PET, PP, Shink Sleeve, IML, jj., Filimi e ngata ea polasetiki. (12 micron -500micron)

Tlhaloso e ka Sehloohong ea Theknoloji

| Mohlala | Mohlala oa ZJR-450G |

| Lebelo le Phahameng la Khatiso | 180m/motsotso |

| 'Mala oa Khatiso | 7mebala |

| Bophara bo boholooPampiri | 470mm |

| Bophara ba ho Hatisa bo Holimo | 450mm |

| Bophara bo phahameng ba ho phutholoha | 900mm |

| Bophara ba Max. Bokgutlisa Botjha | 900mm |

| Bolelele ba Khatiso | Z76-Z192(241.3mm-609.6mm) |

| Litekanyo (8)Colors+3Dke hore, ho Seha) | 10.83mx 1.68mx 1.52m (Bophara x Bophara x Bophahamo) |

LITŠOANTŠO TSA MOCHINE:

3) Bareng ea ho Retelehela e ka Etsoang

4) Skrine e ka Susumetsoang ea ho Ama

5) Yuniti ea Matrix (e nang le yuniti ea ho seha ka die) + Sethunya sa Makenete sa Roller

Tlhophiso ea Mochini:

Sistimi ea Taolo ea Othomathiki

-Tsa morao-raoSiemenssistimi ea taolo

-Ts'ebetso ka Senyesemane le Sechaena

-Senoro sa ngoliso (P+F)

-Automatic phoso bonoa le tsamaiso ea alamo

-Sistimi ea ho hlahloba video ea BST (mefuta ea 4000)

-Phepelo ea Matla: 380V-400V ,3P , 50HZ-60HZ

Sistimi ea ho Fepa Lintho

-E ntsha moea o kenang ka letsoho ka ho phahamisa moea (Bophara bo boholo:900mm)

-Sebaka sa moea (lisenthimithara tse 3)

-E iketsahalla ka bohona ebile e qhibilihile

-Lenonyello le potolohang la pneumatic

-Brake ea phofo ea makenete

-Taolo ea tsitsipano e iketsang

-Sistimi ea ho emisa ka boiketsetso bakeng sa khaello ea thepa

Sistimi ea tataiso ea webo ea -RE

-E fepuoa ke enjene ea servo (Siemensenjene ea servo)

Sistimi ea Khatiso

-Yuniti ea khatiso ea Super flexo

-Silindara ea khatiso e laoloa ke enjene e ikemetseng e tsamaisoang ka kotloloho (ho qoba ho tšoaea gear)

-Silindara ea ho hatisa e nang le sleeve, e bobebe ebile e bonolo ho e fetola.

-Poleiti ea khatiso: lipoleiti tse kentsoeng letsohong

-Rolara e se nang maikutlo le rolara e futhumatsang metsi.

-Roller ea chiller ea metsi e tsamaisoang ke enjene e ikemetseng ea servo 'me e ka hatisa filimi ea polasetiki hantle.

-Sistimi ea potoloho ea mali e iketsang e pholileng

-Rolara e se nang maikutlo le sehatsetsi sa metsi li entsoe ka enke e arohaneng, e lekanang ka har'a rolara ea maikutlo, ho ka ba bonolo ho e hloekisa hobane ntle le ho e hloekisa ka mahlaseli a letsatsi.

-Khatiso e 'ngoe le e 'ngoeyuniti e na leenjene ea servo e 'melitaolo.

Servo 1 e laola sleeve ea ho printa, 'me Servo 2 e laola rolara e kholo ea meropa ea chiller..

-Pele ho ngodisoe laoloa ke enjene ea servo, 'me enjene e tla bala ka bo eona ha u kenya bolelele ba khatiso skrineng se seholo sa ho ama. Sekoahelo sa khatiso se tla ea motheong oa boemo bo tsamaellanang ntlheng ea lefela sekoahelong.

-Ngoliso e lefelloange lokela ho lokisoa skrineng se amang

Ha o etsa rejistara e nepahetseng ya mmala, bula sensor ya rejistara ho bala letshwao la kgatiso mme mochini o ka etsa rejistara e iketsang kamehla.

-Phanele ea ts'ebetso bakeng sa phetoho e ntle ka mosebetsi oa ho iketsa

-Phetoho e ntle ea khatello bakeng sa mojari

-Khatello e pakeng tsa rolara ea anilox, poleiti ea khatiso le thepa e tla lokisoa hantle ke bere eo

E laoloa ke enjene e nyane. E ka tsamaisoa habonolo ka senotlolo se hoketsoeng.

-Pase ea Bobeli ka sensor ea ngoliso (P+F)

-Ho bonolo ho tlosa rolara ea anilox

-Terei ea enke e bonolo ho e tlosa, e iketsa holimo/tlase

-Skrine ea ho ama e tsamaeang (ts'ebetso e bonolo)

-Mohala oa ho sireletsa mochini oohle (Schneider-France)

Sesebelisoa sa ho omisa UV (Setsi se pholileng sa fene sa 9KW ka yuniti)

Letšoao la -UV Ray le tsoang Italy, Stepless electronic UV

-Taolo ea matla e ikemetseng bakeng sa mochini o mong le o mong oa UV dryer

-E fetola motlakase ka bohona ho latela lebelo la ho hatisa

-Taolo e iketsang ka mosi oa UV

-Phanele ea taolo ea UV e ikemetseng

Sistimi ea ho Khutlela morao

-E khannoa ke enjene e ikemetseng ea servo (mosi oa moea oa lisenthimithara tse 3)

-Rewinder habeli bakeng sa khetho

-E iketsahalla ka bohona ebile e qhibilihile

-SMC Pneumatic swivel

Sistimi ea taolo ea tsitsipano ea RE e iketsang

-Rewinder e nang le lifti ea pneumatic (Bophara bo boholo:900mm)

Phetoho e ka Sehloohong

| ● TSAMAISO EA TAOLO | |||

| Tlhaloso | Hlokomela | Bongata | Lebitso la Letšoao |

| Sistimi ea Taolo ea Khomphutha | Sistimi ea Taolo ea Mekhahlelo e Mengata | 1 | Siemens(Jeremane) |

| PLC | 1 | Siemens(Jeremane) | |

| Mojule o Atolosang oa PLC | 1 | Siemens(Jeremane) | |

| Mojule oa Analoge | 1 | Siemens(Jeremane) | |

| Skrine ea ho Ama bakeng sa Mochini o ka Sehloohong | 'Mala oa 'Nete | 1 | Siemens(Jeremane) |

| Mojule oa IO o hole | 1 | Phoenix (Jeremane) | |

| Phetoho ea Moea | 1 | Schneider (Fora) | |

| Switjha/ Konopo | 8 | Schneider (Fora) | |

| Mokgokaganyi | 5 | Schneider (Fora) | |

| Phepelo ea Motlakase ea ho Fetola | 1 | Meanwell (Taiwan) | |

| Polaka ea Lifofane&Boloko ba Terminal | 6 | SIBAS | |

| ● YUNITI E 'NGOE LE E 'NGOE EA KHATISO | |||

| Tlhaloso | Hlokomela | Bongata | Lebitso la Letšoao |

| Mochini oa Servo oa Roller oa Metsi o Chesang | 1 | Siemens(Jeremane) | |

| Mochini oa Servo oa Roller oa Metsi o Chesang | 1 | Siemens(Jeremane) | |

| Mochini oa Servo oa ho Hatisa Foromo | 1 | Siemens(Jeremane) | |

| Foromo ea ho Hatisa Roller Servo e Tsamaiswang | 1 | Siemens(Jeremane) | |

| Setlolo se Ikhethileng sa ho Hlakola | 1 | SH1MPO-ABLEHA(Japane) | |

| Phetoho ea Moeli | 8 | Schneider (Fora) | |

| Tsela e Otlolohileng ea Tataiso | 4 | PMI (Taiwan) | |

| Silindara | 14 | SMC (Japane) | |

| href="#/javascript:;" SolenoidValve | 10 | SMC (Japane) | |

| ● TSAMAISO EA HO FETISA WEB | |||

| Tlhaloso | Hlokomela | Bongata | Lebitso la Letšoao |

| Enjene ea Servo | 3KW | 2 | Siemens(Jeremane) |

| Mokhanni oa Servo Motor | 2 | Siemens(Jeremane) | |

| Setlolo se khethehileng sa ho fokotsa mosi | 2 | SH1MPO-ABLEHA(Japane) | |

| Fothosele bakeng sa moqolo oa ho qetela | 1 | Schneider (Fora) | |

| ● TSAMAISO EA HO KHUTLISA TSELA | |||

| Tlhaloso | Hlokomela | Bongata | Lebitso la Letšoao |

| Enjene ea Servo | 1 | Siemens(Jeremane) | |

| Sensor | 1 | RE – Italy | |

| Fetola | Tse 'maloa | Schneider (Fora) | |

| ● TSAMAISO EA HO HLAKOLA | |||

| Tlhaloso | Hlokomela | Bongata | Lebitso la Letšoao |

| Tataiso ea webo ea Ultrasonic | 1 | RE – Italy | |

| Sesebelisoa sa phofo ea makenete | 1 | RE – Italy | |

| Sensor | 1 | RE – Italy | |

| Fetola | Tse 'maloa | Schneider (Fora) | |

| ● TSAMAISO E 'NGOE | |||

| Tlhaloso | Hlokomela | Bongata | Lebitso la Letšoao |

| Sistimi ea ho omisa UV |

| SETE e le 1 | Mahlaseli a UV-Italy |

| Sistimi ea Video |

| SETE e le 1 | BST (Jeremane) |

Mochini o sebetsang sebakeng sa rona sa mosebetsi:

KOPO EA RŌNA EA CNC

Mehlala e meng ea Khatiso: