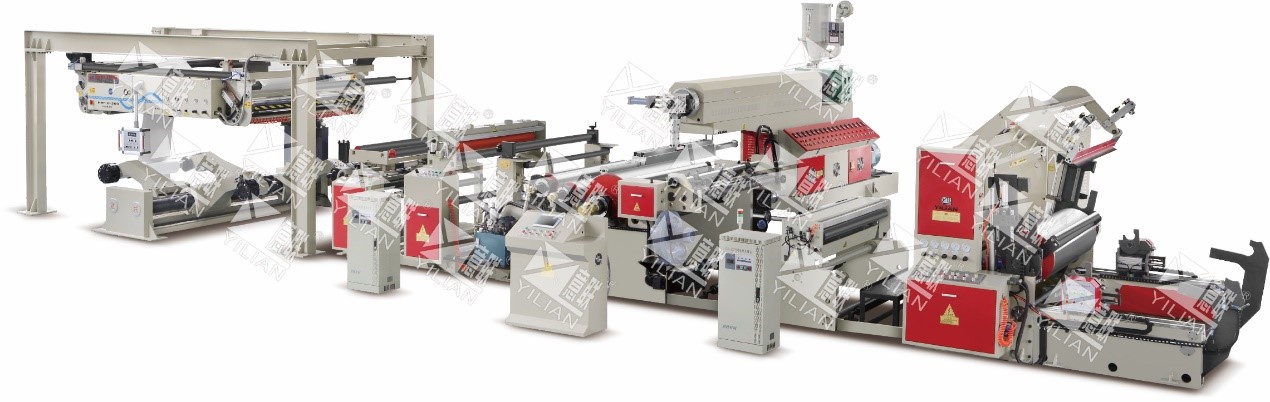

Mashiinka Dahaarka PE ee Waraaqaha Tooska ah ee WSFM1300C

| Resin laminating ah oo ku habboon | LDPE, PP iwm. |

| Waxyaabaha saldhigga ku habboon | warqad (80—400g/m²) |

| Xawaaraha ugu badan ee farsamada | 300m/min (xawaaraha shaqada wuxuu ku xiran yahay dhumucda daahan, ballaca) |

| Ballaca dahaarka | 600—1200, ballaca duubista hagaha: 1300mm |

| Dhumucda dahaarka | 0.008—0.05mm (Boorno keli ah) |

| Qalad dhumucdiisuna tahay dahaarka | ≤±5% |

| Kala duwanaanshaha dejinta xiisadda otomaatiga ah | 3—100kg oo ah faa'iido buuxda |

| Tirada ugu badan ee qalabka wax lagu shubo | 250 kg/saacaddii |

| Rullaluistemadka qaboojinta ee xarunta | ∅800 × 1300 |

| Dhexroorka boolal | Saamiga ∅110mm35:1 |

| Dhexroorka ugu badan ee dabacsan | ∅1600mm |

| Dhexroorka ugu badan ee dib u wareegida | ∅1600mm |

| Dhexroorka xudunta warqadda ee kala fog: 3″6″ iyo dhexroorka xudunta warqadda ee dib u socon kara: 3″6″ | |

| Extruder-ka waxaa ku shaqeeya 45kw | |

| Awood guud | qiyaastii 200 Kw |

| Miisaanka mashiinka | qiyaastii 39000kg |

| Cabbirka dibadda | 16110 mm × 10500 mm × 3800 mm |

| Midabka jirka ee mashiinka | Cawlan iyo Casaan |

1. Qaybta dabacsan (oo leh PLC, nasashada servo)

1.1 Qaab-dhismeedka furfuran

Qaab-dhismeedka: Qaab-dhismeedka dabacsan ee aan lahayn usha Haydarooliga

Kala-goysyada taxanaha BA waxay sameeyaan qayb muhiim ah oo ka mid ah xariiqda dahaarka waxaana lagu rakibayaa meesha laalaabka ah ee hoos timaada qaab-dhismeedka buundada. Waxay u oggolaanaysaa sii socoshada socodsiinta duubka warqadda ee jira ilaa duubka warqadda ee xiga iyada oo aan la joojin wax soo saarka.

Qaababka dhinaca ee isku-xidhka waxaa ku jira 2 madax oo is-xoqid ah iyo qayb taageero dhexe oo dhaqaaqi karta. Korkiisa waxaa ku yaal 2 rodol oo is-xoqid ah.

Nidaamka capstan roll, reverse idler roll iyo double dancer ayaa sameeya qaybta ururinta waraaqaha taasoo awood u leh inay ururiso warqad ilaa 4 jeer dhererka splicer-ka.

Mashiinka waxaa lagu shaqeeyaa iyada oo loo marayo guddiga hawlgalka ee mashiinka

Xawaaraha isku xirka warqadda Ugu badnaan.300m/daqiiqo

a) marka xoogga warqaddu ka sarreeyo 0.45KG/mm, ugu badnaan 300m/daqiiqo;

b) marka xoogga warqaddu ka sarreeyo 0.4KG/mm, ugu badnaan 250m/daqiiqo;

c) marka xoogga warqaddu ka sarreeyo 0.35KG/mm, ugu badnaan 150m/daqiiqo;

Ballaca warqadda

Ugu badnaan. 1200mm

Ugu yaraan 500mm

Xawaaraha CE-300

Ugu badnaan. 300m/daqiiqo

Xogta sambabbada

Deji cadaadiska 6.5 baar

Cadaadiska ugu yar 6 bar

Nooca CE-300

Koronto 3.2kVA, 380VAC/50Hz/20A

Danabka xakamaynta 12VDC/24VDC

1.1.1 Nooca gacanta ee madaxa-bannaan ee isku xidhka usha haydarooliga oo leh laba-jibbaaran oo ah nasasho, iyada oo aan lahayn usha hawada, rarista haydarooliga, waxay badbaadinaysaa kharashka rarista qaab-dhismeedka farsamada. Beddelka otomaatiga ah ee usha AB ee otomaatiga ah, qashin yar oo walxaha ah.

1.1.2 Ugu badnaan. dahaarka nasashada: ¢ 1600mm

1.1.3 Kala duwanaanshaha dejinta xiisadda otomaatiga ah : 3—70kg oo ah farqiga buuxa

1.1.4 saxnaanta xiisadda: ± 0.2kg

1.1.5 xudunta warqada: 3" 6"

1.1.6 Nidaamka xakamaynta xiisadda: nooca shabagga ee qalabka ogaanshaha xiisadda iyadoo la adeegsanayo xiisadda ogaanshaha potentiometer-ka saxda ah, xakamaynta dhexe ee PLC-ga la barnaamijin karo

1.1.7 Nidaamka xakamaynta darawalka: PIH silinda bareegga, jawaab celinta encoder-ka wareega si dhakhso leh, cadaadiska saxda ah ee nidaamiya waalka xakamaynta wareegga xiran, kontoroolka la barnaamijin karo ee PLC xakamaynta dhexe

1.1.8 Dejinta xiisadda: Iyada oo loo marayo dejinta waalka cadaadiska saxda ah

1.2 Nooca kaydinta ee qalabka goynta otomaatiga ah, soo qaadashada iyo jarista

1.2.1 Kaydinta oo ay wado kaydka matoorka ee pneumatic-ka ah, hubi xiisad deggan marka aad soo qaadayso warqadda.

1.2.2 Qaab-dhismeedka goynta gaarka ah

1.2.3 PLC si otomaatig ah u xisaabi xawaaraha cusub ee wareega ee usha, oo xawaaraha ku hay xawaaraha khadka ugu weyn

1.2.4 Hel duubka riixitaanka walxaha, gooyaha jabay . beddelka xakamaynta xiisadda, dib u deji dhammaantood si toos ah ayay u dhammaan karaan

1.2.5 Qalabka digniinta hore ee isbeddelka duubista,: dhexroorka shaqada marka la gaaro 150mm., mashiinka ayaa qaylo-dhaan doona

1.3 Xakamaynta sixitaanka: nidaamka xakamaynta hagaajinta qalabka sawir-qaadista (qaab-dhismeedka bst)

2. Corona (Yilian customized)

Awoodda daaweynta Corona: 20 kw

3. Cutubka dahaarka Haydarooliga:

3.1 Qaab-dhismeedka isku-dhafka saddex-rodol oo dahaadh ah, duubista gadaal-riix, waxay ka dhigi kartaa xoog orso-rogaal-rog isku-dhafan oo siman, adag isku-dhafan.

3.2 Ka saarista duubka caagga ah ee silikoon: badeecada isku dhafan way fududahay in laga fiirsado duubka qaboojinta, Haydarooliga si adag ayuu u riixi karaa.

3.3 Qaab-dhismeedka simitaanka filimka duuban ee qaloocan,: wuxuu ka dhigi karaa filimku mid si dhakhso ah loo hawlgeliyo

3.4 Qalabka quudinta ee isku-dhafka ah ayaa hagaajiya duubista si ay uga gudubto dhumucda walxaha filimka oo aan sinnayn iyo wixii la mid ah daciifnimada.

3.5 Qalabka afuufa ee cadaadiska sare leh ayaa si dhakhso ah u nuugaya geesaha qashinka.

3.6 Rullaluistemka goynta ee ka soo baxa isku-dhafka ah

3.7 Roogga isku-dhafka ah waxaa ku shaqeeya matoor ku tiirsanaan

3.8 Matoorka isku-dhafka ah ee lagu riixo waxaa maamula koontaroolaha soo noqnoqda ee Japan

Faahfaahin:

(1) Rullaluistem isku dhafan: ¢ 800 × 1300mm 1 xabbo

(2) Rullaluistemadka caagga ah: ¢ 260 × 1300mm 1 xabbo

(3) duubista riixa: ¢ 300 × 1300 mm 1 xabbo

(4) dhululubo saliid ah oo isku dhafan: ¢ 63 × 150 2 xabbo

(5) Ka soo bixi duubka: ¢130 × 1300 1 xabbo

(6) 11KWmotor(SHANGHAI) 1set

(7)11KW Beddelaha Soo noqnoqoshada (JAPAN YASKAWA)

(8) isku xidhaha wareega: (2.5"2 1.25"4)

4. Qalab-saare (hagaajinta dhererka otomaatiga ah)

4.1 Dhexroorka boolal:¢ 110, Qalabka ugu badan ee wax lagu shubo waa :250kg/saacaddii (Tiknoolajiyadda Japan)

4.2 T-die( Taiwan GMA)

4.2.1 Ballaca caaryada: 1400mm

4.2.2 Ballaca wax ku oolka ah ee caaryada: 500-1200mm

4.2.3 Farqiga bushimaha caaryada: 0.8mm, dhumucda dahaarka: 0.008—0.05mm

4.2.4 Khalad dhumucda dahaadhka ah: ≤±5%

4.2.5 Tuubada kulaylinta korontada ee gudaha kulaylinta, kululaynta si heer sare ah waxtar u leh, heerkulku si dhakhso ah ayuu u kordhaa

4.2.6 Meel gebi ahaanba xiran, Hagaajinta ballaca buuxinta

4.3 Beddel degdeg ah aaladaha shabakadda

4.4 Socodka hore iyo gadaal, si toos ah ayuu u qaadi karaa gaariga xamuulka qaada, masaafada kor u qaadista: 0-100mm

4.5 Qaab 7 meelood oo xakamaynta heerkulka ah. Foosto boolal ah 8 qaybood oo xakamaynta heerkulka ah. isku xirka 2 meelood oo xakamaynta heerkulka ah ayaa qaada cutubyada kululaynta Infrared.

4.6 Sanduuqa geerka ee yareeya awoodda weyn, ILKAHA ADAG (Guo tai guo mao)

4.7 Xakamaynta heerkulka dijitaalka ah ee xakamaynta heerkulka otomaatiga ah

Qaybaha ugu muhiimsan:

(1) Matoorka AC-ga 45kw (SHANGHAI)

(2) Beddelaha soo noqnoqda ee 45KW (JAPAN YASKAWA)

(3) Xakameeyaha heerkulka dijitaalka ah 18 xabbo

(4) Matoorka socodka ee 1.5KW

5. Qalabka jarista mindi wareegsan oo Pneumatic ah

5.1 Qalabka hagaajinta boolal trapezoidal ah, beddel ballaca jarista warqadda

5.2 Mashiinka jarista cadaadiska hawada

5.3 5.5kw oo ah gees cadaadis sare leh

6. Cutubka Dib-u-habaynta: Qaab-dhismeedka shaqada culus ee 3D

6.1 Qaab-dhismeedka Dib-u-soo-celinta:

6.1.1 Mashiinka dib-u-warshadaynta laba-geesoodka ah ee korontada nooca is-qabsiga, jarista otomaatiga ah ee xawaaraha sare leh iyo soo-qaadista walxaha la dhammeeyay, dejinta otomaatiga ah.

6.1.2 Dhexroorka ugu badan ee dib u rogidda: ¢ 1600 mm

6.1.3 xawaaraha rogrogmada: 1r/daqiiqo

6.1.4 xiisad:3-70kg

6.1.5 Saxnaanta xiisadda: ± 0.2kg

6.1.6 xudunta warqadda: 3″ 6″

6.1.7 Nidaamka Xakamaynta Xiisadda: Barkinta dhululubada ayaa dul sabeynaysa qaab-dhismeedka nooca duubista ee sabeynaya, xiisadda waxaa lagu ogaadaa potentiometer-ka saxda ah, kantaroolaha la barnaamijin karo ee PLC-na wuxuu si dhexe u xakameeyaa xiisadda. (Silsilad isjiidjiid hoose oo Japan SMC ah) 1 set

6.1.8 Nidaamka Xakamaynta Darawalka: 11KW darawalka matoorka, jawaab celinta xawaaraha cod-bixiyaha wareega, Senlan AC inverter laba-laab ah oo xiran, koontaroolka la barnaamijin karo ee PLC xakamaynta dhexe. 1 set

6.1.9 Dejinta Xiisadda Joogtada ah: Dejinta Xakamaynta Cadaadiska Saxda ah (Japan SMC)

6.1.10 Dejinta xiisadda taper: si aan kala sooc lahayn ayaa loogu dejiyay shaashadda kombiyuutarka, xakamaynta PLC, beddelka saamiga korantada/hawada (Japan SMC)

6.2 Qalabka Quudinta iyo Jarida ee Tooska ah

6.2.1 Rulabyada Taageerada Isku-xidhka waxaa maamula PLC si ay u wadaan matoorka si ay walxaha uga fogeeyaan rulabka xoqidda

6.2.2 Habka Jarjaridda Madaxa-bannaan ee Haydarooliga

6.2.3 Xisaabinta tooska ah ee PLC ee habka soo qaadista, beddelka mugga waxaa lagu dhammeeyaa fure

6.2.4 Shaqada Taageerida Roogga, Qalabka Jaritaanka, Dib u dejinta, iwm. Si Toos ah ayaa loo Dhammeeyay

6.2.5 Tilmaamaha

(1) Rullaluistemka is-jiidjiidka: ¢700x1300mm 1 baar

(2) Matoorka dabaysha: 11KW (Shanghai Lichao) 1 set

(3) Sanduuqa geerka oo rogrogaya: qalabka dib u habeynta geerka ee dusha sare ee adag (Thailand Mau)

(4) Beddelaha: 11KW (Japan Yaskawa) 1 set

(5) Sanduuqa qalabka duubista ee taageerada: 1 qalab oo xoog ah

(6) Yaraynta xawaaraha: ilig adag 1 set oo xoog ah

(7) Yaraynta xawaaraha socodka oo wareegaysa: 1 xabbo oo xoog ah

(8) Saldhigga haydarooliga ee sii deynaya

7. Jiidista usha hawada ee otomaatiga ah

8. Qaybta Darawalka

8.1 Suun gudbinta matoorka ugu weyn wuxuu qaataa suunka isku-dhafan

8.2 Matoorka isku-dhafka ah, dib-u-wareejinta iyo nasashada: Suun wadista ayaa qaata qalabka qaansada, silsiladda iyo gudbinta suunka isku-dhafan.

8.3 Sanduuqa geerka wadista ugu weyn: Shaabadaynta geerka helical-ka ee saliidda lagu dhex milmay, Qaab-dhismeedka gudbinta geerka helical-ka ee khadka ah

9. Cutubka Xakamaynta

Golaha korontada ee madaxa-bannaan, xakamaynta dhexe, goobta isku-dhafka ah oo leh hawlgalka golaha xakamaynta dhexe. Nidaamka otomaatiga ah ee mashiinka oo isticmaalaya qalab PLC ah (hollsys) oo leh awood farsamayn sare, iyo calaamadaha wadahadalka mashiinka oo isticmaalaya isgaarsiinta shabakadda ee u dhaxaysa is-dhexgalka. PLC, cutubka fidinta, is-dhexgalka wadahadalka mashiinka-mashiinka ee u dhexeeya nidaamka wadista iyo waxay ka kooban yihiin nidaam xakameyn otomaatig ah oo isku dhafan. Wixii cabbirro ah, waxaa la dejin karaa, iyadoo la adeegsanayo xisaabin otomaatig ah, xusuusta, ogaanshaha, qaylo-dhaanta, iwm. Ma xiisadda qalabka bandhigga muuqaalka, xawaaraha, dhumucda dahaarka, xawaaraha iyo xaaladaha shaqada ee kala duwan ayaa la samayn karaa.

10. kuwa kale

11.1 Roogga Hagaha: Anodization adag oo ah duubka hagaha aluminiumka, habka dhaqdhaqaaqa

11.2 Qalabka danab hooseeya ee France Schneider, omron Japan, iwm.

11. nooca qaybaha

11.1 PLC (Beijing Hollysys)

11.2 Shaashadda taabashada (TAIWAN)

11.3 soo noqnoqoshada Converter: Japan Yaskawa

11.4 Matoorka ugu weyn: SHANGHAI

Dhululubo 11.5 ah oo is jiidjiid yar leh (SMC Japan)

11.6 XIRIIRAHA AC (Schneider)

Badhanka 11.7 (Schneider)

11. Isku-darka taagan (Taiwan)

11.9 dhululubo oo cadaadis nidaamiya waalka (Taiwan)

11.10 Waalka sarrifka birlabta (Taiwan)

11.11 saxnaanta cadaadiska nidaamiya waalka (SMC)

12. Macmiilku wuxuu bixiyaa adeegyo

12.1 Booska qalabka iyo aasaaska

12.2 Sahayda qalabka ee armaajada korontada ee mashiinka

12.3 Biyo u sahlaya qalabka mashiinka ee gudaha iyo dibadda ka soo galaya albaabka (iibsadaha ayaa diyaarinaya qaboojiyaha biyaha)

12.4 Sahayda gaaska ee mashiinka lagu rakibayo caloosha iyo caloosha

12.5 Tuubada qiiqa iyo marawaxadda

12.6 Ururinta, rarista iyo dejinta walxaha salka ah ee qalabka la dhammeeyay

12.7 Qalab kale oo aan ku jirin qandaraaska

13. Liiska qaybaha dayactirka:

| Maya. | Magaca | Faahfaahin. |

| 1 | Heerkulka isku-xidhka | 3M/4M/5M |

| 2 | Xakamaynta heerkulka | Omroon |

| 3 | Waalka Micro-regulator | 4V210-08 |

| 4 | Waalka Micro-regulator | 4V310-10 |

| 5 | badhanka u dhowaanshaha | 1750 |

| 6 | Gudbinta adag | 150A和75A |

| 7 | badalka safarka | 8108 |

| 10 | cutubka kululaynta | ϕ90*150mm,700W |

| 11 | cutubka kululaynta | ϕ350*100mm,1.7KW |

| 12 | cutubka kululaynta | 242*218mm,1.7KW |

| 13 | cutubka kululaynta | 218 * 218mm, 1KW |

| 14 | cutubka kululaynta | 218*120mm,800W |

| 15 | Badhanka Schneider | ZB2BWM51C/41C/31C |

| 16 | Digsi hawada ah | |

| 17 | Cajalad heerkul sare leh | 50mm*33m |

| 18 | Cajalad Telflon ah | |

| 19 | Daboolka duubista Corona | 200 * 1300mm |

| 20 | Xaashi naxaas ah | |

| 21 | shaandhada shaashadda | |

| 22 | Kala wareeji jeexdinta | 150*80*2.5 |

| 23 | isku xira neef-mareenka | |

| 24 | qoriga cirka | |

| 25 | kala-goyska biyaha | 80A和40A |

| 27 | boolal iyo kuwa kale | |

| 28 | silsilad jiidid | |

| 29 | sanduuqa qalabka |

Qaybaha ugu muhiimsan iyo sawirka:

Unwinder (Isku-darka otomaatiga ah) → hagaha shabakadda → Daawaynta Corona → Qayb ka mid ah fidinta iyo isku-darka Jaritaanka Edge → Dib-u-hagaajinta