Mashiinka Dahaarka Toosan ee FM-E ee Tooska ah

| Moodel | FM-E1080 |

| FM-1080-Cabbirka ugu badan ee warqadda-mm | 1080 × 1100 |

| FM-1080-Daqiiqo. Cabbirka warqadda-mm | 360×290 |

| Xawaaraha-m/daqiiqo | 10-100 |

| Dhumucda warqadda-g/m2 | 80-500 |

| Saxnaanta is dul saaran-mm | ≤±2 |

| Dhumucda filimka (mikrometer-ka caadiga ah) | 10/12/15 |

| Dhumucda xabagta caadiga ah-g/m2 | 4-10 |

| Dhumucda filimka hore ee dhejiska-g/m2 | 1005,1006,1206 (1508 iyo 1208 warqadda qoto dheer ee lagu dhejiyo) |

| Dhererka Quudinta ee aan joogsiga lahayn-mm | 1150 |

| Dhererka warqadda ururiyaha (oo ay ku jiraan baaldi) -mm | 1050 |

| Awoodda ugu weyn ee matoorka-kw | 5 |

| Awood | 380V-50Hz-3PMAwoodda istaagga mashiinka: 65kwAwoodda shaqada: 35-45kwAwoodda kuleylinta 20kwBaahida nasashada: 160A |

| 3 marxaladood oo lagu daray dhulka iyo dhexdhexaad oo leh wareeg | |

| Bamka faakuumka | 80psi Awood: 3kw |

| Duub cadaadiska shaqada-Mpa | 15 |

| Kombaresarada hawada | Socodka mugga: 1.0m3/daqiiqo, Cadaadis la qiimeeyay: 0.8mpa Awood: 5.5kw Mugga hawadu waa inuu ahaado mid joogto ah. Hawada soo socota: tuubo dhexroorkeedu yahay 8mm (Soo jeedi inaad la jaanqaado isha hawada ee dhexe) |

| Dhumucda fiilada-mm2 | 25 |

| Miisaanka | 8000kgs |

| Cabbirka (qaab-dhismeedka) | 8000 * 2200 * 2800mm |

| Soo raraya | Mid ka mid ah 40” Xarunta Dhexe |

Faallo: aqbal habayn cabbirka weyn ee mashiinka iyadoo ku xiran baahida macaamiisha. 1050*1250; 1250*1250mm; 1250*1450mm, 1250*1650mm

FM-E si buuxda otomaatig ah oo toosan oo leh laminator-ka shaqada badan leh oo ah qalab xirfad leh oo loo isticmaalo dahaarka filimada balaastikada ah ee dusha sare ee daabacaadda warqadda.

F Ku dhejinta biyaha ku salaysan (dhejinta polyurethane ee biyaha ku jirta) dahaarka qalalan. (xabagta biyaha ku salaysan, xabagta saliidda ku salaysan, filimka aan xabagta ku jirin)

F Dahaarka kuleylka (filim hore loo dahaadhay/kuleylka)

F Film: OPP, PET, PVC, BIRTA, iwm.

Si ballaaran ayaa loogu dabaqi karaa dahaarka baakadaha, sanduuqa warqadda, buugaagta, joornaalada, jadwalka, kartoonnada, boorsooyinka gacanta, sanduuqa hadiyadaha, warqadda baakadaha khamriga oo hagaajinaysa darajooyinka daabacaadda, iyo gaaritaanka ujeeddada u-adkaysiga boodhka, biyaha u-adkaysiga, iyo saliidda u-adkaysiga. Waa doorashada ugu fiican ee daabacaadda iyo dahaarka shirkadaha dhammaan miisaanka.

Cabbirka rarista warqadda iyada oo loo marayo shaashadda geli qor, oo si buuxda otomaatig u ah mashiinka oo dhan.

Naqshadeynta warshadaha ee xirfadeysan, habka rinjiga buufinta, waa mid wax ku ool ah oo qurux badan.

Quudiyaha warqadda gudbinta hawada oo tayo sare leh oo leh 4 nuuge oo loogu talagalay qaadista warqadda iyo 4 nuuge oo loogu talagalay gudbinta warqadda si loo hubiyo quudinta warqadda oo deggan oo degdeg ah. Aan joogsanayn oo leh cutub ka horreeya tuulmada.isku-darka waxaa xakameeya matoorka servo, hubi saxnaanta.

Saxanka raritaanka warqadda oo leh 304 saxan oo bir ah oo aan miridh lahayn.

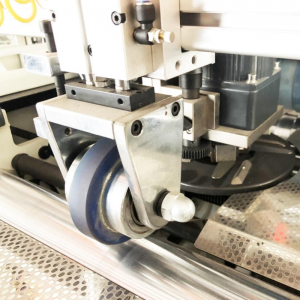

Cutubka laminator-ka laba-shaqo toosan, duubiyaha kululaynta birta ee dhexroorkiisu yahay 380mm waxaa lagu xakameeyaa nidaamka kuleylinta elektromagnetic-ka, hufnaan sare iyo keydinta tamarta, waxay hubin doontaa shuruudaha dahaarka filimka ee alaabada tayada sare leh. duubiyaha kululaynta qalajinta dhexroorkiisu yahay 800mm, duubiyaha cadaadiska caagga ah ee dhexroorkiisu yahay 380mm, duubiyaha sare ee chrome-ka lagu dahaadhay, duubiyaha hagaha iyo saxanka xabagta oo leh xabagta farsamaynta Teflon oo si fudud loo nadiifin karo.

Shaqada mindi dhulka ah oo ku habboon filimka BOPP iyo OPP. Shaqada mindi kulul oo ku habboon jarista filimka PET iyo PVC.

Qaab-dhismeedka korontada wuxuu inta badan qaataa nidaamka xakamaynta korontada ee Taiwan Delta iyo qalabka korontada ee Faransiiska Schneider.

Qaybta Ururinta: Si habsami leh oo otomaatig ah oo aan joogsi lahayn.

Qaadista gaadhiga dheeraadka ah ee filimka duubista, Hawlgal madax-bannaan oo qof keli ah.

| QAYBTA QAADAHA | FM-E | |

| 1 | Habka quudinta jet-ka | ★ |

| 2 | Quudiyaha Xawaaraha Sare | ★ |

| 3 | Darawalka adeegga quudinta | ikhtiyaari ah |

| 5 | Bamka faakuumka ee BECKER | ★ |

| 6 | Warqad quudin aan joogsanayn oo qalabka ka hor xidhmo | ★ |

| 7 | Xakamaynta servo-ga ee is dulsaaran | ★ |

| 8 | Dhinaca cabbiraadda | ★ |

| 9 | Saxan warqad ah oo leh Max & Min xaddidan | ★ |

| 10 | Qalabka ka saarista boodhka | ⚪ |

| 11 | Qalabka dahaarka daaqadda (dahaarka iyo qalajinta) | ⚪ |

| QAYBTA DAMINATADA | ||

| 1 | Foorno kuleyliye dheeri ah | ★ |

| 2 | Dhexroorka duubista qalalan | 800mm |

| 3 | Rooliga qalalan Nidaamka kuleylka elektromagnetka | ⚪ |

| 4 | Nidaamka heerkulka joogtada ah ee caqliga leh | ★ |

| 5 | Furitaanka pneumatic ee foornada dheeraadka ah | ⚪ |

| 6 | Duub kululeyn oo leh daaweynta Chromium | ★ |

| 8 | Nidaamka kuleylinta elektromagnetic-ka | ★ |

| 9 | Duub cadaadis caag ah | ★ |

| 10 | Hagaajinta cadaadiska tooska ah | ★ |

| 11 | Silsiladda Darawalka KMC-Taiwan | ★ |

| 12 | Ogaanshaha seegista warqadda | ★ |

| 13 | Daaweynta Teflon ee nidaamka dhejiska | ★ |

| 14 | Saliidaynta iyo qaboojinta otomaatiga ah | ★ |

| 15 | Guddiga xakamaynta shaashadda taabashada ee la saari karo | ★ |

| 16 | Qaadista gaadhiga dheeraadka ah | ★ |

| 17 | Filim duuban oo badan oo shaqeynaya - dhidibka simbiriirixan | ⚪ |

| 18 | Riixista duubista kulul ee labajibbaaran | ⚪ |

| 19 | Rullaluisteyaasha dhejiska ah | ⚪ |

| QAYBTA JARJIRKA OTOMAATIGA AH | ||

| 1 | Cutubka mindi wareegsan | ★ |

| 2 | Cutubka mindi silsilad ah | ⚪ |

| 3 | Cutubka mindi kulul | ⚪ |

| 4 | Qalabka filimka jebinta suunka ciidda | ★ |

| 5 | Rullaluistemka ka hortagga duubista warqadda | ★ |

| 6 | Kombaresarada hawada ee nooca boolal | ⚪ |

| URURIN | ||

| 1 | Gaarsiinta otomaatiga ah ee aan joogsiga lahayn | ★ |

| 2 | Qaab-dhismeedka ururinta iyo nadiifinta pneumatic | ★ |

| 3 | Miiska xaashida | ★ |

| 4 | Looxa warqadda sawir-qaadista ee sawir-qaadista ayaa dhacaya | ⚪ |

| 5 | Ururinta warqadda hoos u dhigista otomaatiga ah | ★ |

| QAYBAHA ELEKTRONIGA AH | ||

| 1 | Qaybaha korontada ee tayo sare leh | OMRON/SCHNEIDER |

| 2 | Nidaamka xakamaynta | Delta-Taiwan |

| 3 | Matoorka Adeegga | Tiknoolajiyadda Weikeda-Jarmalka |

| 4 | Shaashadda taabashada ee Kormeeraha Main-14 inji | Tiknoolajiyadda Samkoon-Japanese |

| 5 | Shaashadda taabashada mindi silsilad ah iyo mindi kulul - 7 inji | Tiknoolajiyadda Samkoon-Japanese |

| 6 | Beddelaha | Delta-Taiwan |

| 7 | Dareemaha/Encoderka | Omron-Japan |

| 8 | Beddel | Schneider-Faransiis |

| QAYBAHA CIRRIDKA | ||

| 1 | Qaybaha | Airtac-Taiwan |

| Dhalinyaro | ||

| 1 | dhalista ugu weyn | NSK-Japan |

①Quudiyaha xawaaraha sare leh ee aan joogsiga lahayn:

4 nuuge oo loogu talagalay qaadista warqadda iyo 4 nuuge oo loogu talagalay gudbinta warqadda si loo hubiyo quudinta warqadda oo deggan oo degdeg ah. Xawaaraha ugu badan ee quudinta 12,000 xaashi/saacaddii.

Quudiyaha xawaaraha sare leh

Gaadiidka warqadda deggan

Tilmaamaha Dhinaca ee Tooska ah Ku hay is dulsaarka ≤±2mm

②Cutubka laminating:

Moodeelka E oo leh diameter weyn. 800mm oo duuban qalalan iyo foorno kaaliye ah oo loogu talagalay qalajiyaha degdega ah.

Nidaamka kuleylinta elektromagnetka (roller kuleyliyaha oo keliya)

Faa'iidooyinka: kululaynta degdega ah, cimri dheer; ammaan ah oo la isku halleyn karo; wax ku ool ah oo keydin tamar; xakamaynta heerkulka saxda ah; dahaarka wanaagsan; hagaajinta jawiga shaqada.

Elektromagnetic kululaynta xakameeye silsiladda wadista cutubka laminating laga bilaabo Taiwan.

Foornada Qallajinta Kaaliyaha ah ee Dahaarka xabagta iyo duubista cabbirka xabagta oo leh dhumuc dahaarka Chromium

daahan sax sare matoorka ugu weyn

Qalab jarista iyo duubista filimka dheeraadka ah

Dareemaha jebinta warqadda, mashiinka quudinta gaaban ayaa joogsan doona, shaqadani si wax ku ool ah ayay uga fogaan doontaa in lagu duubo xabag.Mashiinku wuu shaqeeyaa, waana hawlgal fudud oo uu sameeyo hal hawlwadeen.

Mashiinku wuu shaqeeyaa, waana hawlgal fudud oo uu sameeyo hal hawlwadeen.

③Mindi wareegsan

Jarista mindi wareegsan waxaa lagu dabaqi karaa in ka badan 100 garaam oo warqad ah, sameynta 100 garaam oo warqad ah waa inay si habboon u yareysaa xawaaraha. Hubi in warqadda siman tahay ka dib marka la jaro. Mindida duulista oo leh 4 daab, wareeg laba jiho ah, iyo isku-dubaridka xawaaraha mashiinka ugu weyn, ayaa sidoo kale hagaajin kara saamiga xawaaraha. Iyada oo la adeegsanayo qaab-dhismeedka giraangiraha hagaha, xalli dhibaatada geeska filimka.

Bixinta warqadda Qaybaha pneumatic waxay qaataan Taiwan Airtac.

Qalabka jarista mindi wareegsan iyo qalabka duubista boodboodka.

④mindi kulul iyo mindi wareegsan

Habka Jarida 1: Goynta duulista-jarista ee Rotary farsamo.

Jarista mindi wareeg ah waxaa lagu dabaqi karaa in ka badan 100 garaam oo warqad ah, soo saarista 100 garaam oo warqad ah ayaa loo baahan yahay si loo yareeyo xawaaraha. Hubi in warqadda siman tahay ka dib marka la jaro. Mindida duulista oo leh 4 daab, wareeg laba jiho ah, iyo isku-dubaridka xawaaraha mashiinka ugu weyn, ayaa sidoo kale hagaajin kara saamiga xawaaraha. Iyada oo la adeegsanayo qaab-dhismeedka giraangiraha hagaha, xalli dhibaatada geeska filimka.

Habka Jarida: Habka mindiyaha silsiladda ah. (IKHTIYAARI AH)

Mindi silsilad ah iyo qalab goynta mindi kulul oo si gaar ah loogu talagalay jarista warqad khafiif ah oo loogu talagalay filimka PET, Waxay ku habboon tahay jarista BOPP, filimka OPP.

Filimka PET oo leh xoog dhegdheg iyo waxqabad ka hortag ah oo ka sarreeya filimka caadiga ah, mindi silsilad ah oo si fudud loo jari karo filimka PET, aad ayuu ugu habboon yahay ka dib-u-samaynta, si weyn ayuu u yareeyaa shaqada, waqtiga iyo qashinka aan caadiga ahayn, sidaas darteed wuxuu yareeyaa kharashka, waa caawiye wanaagsan oo loogu talagalay jarista warqadda. Qalabka silsiladda waxaa si madax-bannaan u maamula matoorka servo, waa hawlgal iyo dayactir fudud.

Habka jarista: farsamada mindi kulul. (IKHTIYAARI AH)

Haystaha mindiyaha wareegga.

Kuleylinta geeska mindi si toos ah, iyadoo la shaqeyneysa koronto yar oo ammaan ah 24v, Kuleylin degdeg ah iyo qaboojin.

Dareemaha, ogaanshaha xasaasiga ah ee isbeddellada dhumucda warqadda, si sax ah u go'aami booska jarista warqadda.

Muuji. Mindi kulul ayaa si toos ah u soo saarta heerkul kala duwan, iyadoo loo eegayo cabbirrada iyo cabbirrada kala duwan ee warqadda, si loo hubiyo jarista siman.

Encoder-ka Dareemaha booska mindi kulul (la soco dhumucda warqadda: Sidoo kale ku habboon kartoonka dahabka iyo lacagta.)

⑤Unug ururin aan joogsi lahayn

Mashiinka ururinta waraaqaha ee otomaatiga ah ee aan joogsiga lahayn ee mashiinka dahaarka leh wuxuu leeyahay shaqada ururinta waraaqaha iyada oo aan la xidhin; cabbirka ururinta waxaa la jaan qaadayaa quudiyaha warqadda.

Qaadaha filimka

Qaybaha dayactirka

| Maya. | Magaca | Summada | Asal ahaan |

| 1 | Matoorka ugu weyn | Bolilay | Zhejiang |

| 2 | Quudiyaha | Runze | Zhuji |

| 3 | Bamka faakuumka | Tongyou | Jiangsu |

| 4 | Dhalista | NSK | Jabaan |

| 5 | Beddelaha soo noqnoqda | Delta | Taiwan |

| 6 | Badhan fidsan oo cagaar ah | Schneider | Faransiiska |

| 7 | Badhan cas oo fidsan | Schneider | Faransiiska |

| 8 | Badhanka xoqidda | Schneider | Faransiiska |

| 9 | Badhanka Rotary | Schneider | Faransiiska |

| 10 | kontoroolka AC | Schneider | Faransiiska |

| 11 | Matoorka Adeegga | Weikeda | Shenzhen |

| 12 | Darawalka Servo | Weikeda | Shenzhen |

| 13 | Qalabka dhimista adeegga | Taiyi | Shanghai |

| 14 | Awoodda badalka | Delta | Taiwan |

| 15 | Qaybta heerkulka | Delta | Taiwan |

| 16 | Xakameeyaha macquulka ah ee la barnaamijin karo | Delta | Taiwan |

| 17 | Iska caabbinta biriiga | Delta | Taiwan |

| 18 | Silsilad | AIRTAC | Shanghai |

| 19 | waalka elektromagnetic-ka | AIRTAC | Shanghai |

| 20 | Shaashadda taabashada | Xiankong | Shenzhen |

| 21 | Jebiye | CHNT | Wenzhou |

| 22 | bamka Haydarooliga | Tiandi Haydarooliga | Ningbo |

| 23 | Silsilad | KMC | Hangzhou |

| 24 | Suunka gudbiyaha | Hulong | Wenzhou |

| 25 | Bamka diaphragm-ka ee hal-jid ah | FAZER | Wenzhou |

| 26 | Marwaxad jiidid | Yinniu | Taizhou |

| 27 | Encoder-ka | Omroon | Jabaan |

| 28 | Matoorka rogrogaya | Shanghe | Shanghai |

| 29 | Dareemaha mindi silsilad ah | microsonic | Jarmalka |

| 30 | Mindi silsilad ah oo adeeg ah-Ikhtiyaar | Weikeda | Shenzhen |

| 31 | Shaashadda taabashada mindi silsilad ah-Ikhtiyaar | Weinview | Taiwan |

| 32 | Mindi kulul oo adeeg ah | Keyence | Jabaan |

| 33 | Mindi kulul oo adeeg ah | Weikeda | Shenzhen |

| 34 | Shaashadda taabashada mindi kulul - ikhtiyaar | Weinview | Taiwan |

Fiiro gaar ah: sawirrada iyo xogta loogu talagalay tixraac keliya, way isbeddelaan iyada oo aan ogeysiis la bixin.

Wax soo saarka hal wareeg ah:

Filim BOPP ah oo leh warqad cad oo caadi ah 9500 xaashi/saacaddii (sida ku cad warqadda quarto).

Tirada hawl wadeennada:

Hal hawlwadeen weyn iyo hal hawlwadeen caawiye ah.

Haddii isticmaaluhu uu bilaabo laba shaqo maalintii, boos kasta wuxuu kordhiyaa hal hawlwadeen.

Koollo iyo filim:

Badanaa waxaa loo hayaa xabagta biyaha ku salaysan ama filimka aan ka badnayn 6 bilood; Ku dheji si fiican u qalaji ka dib habka daminta, waxay hubin doontaa in tayada daminta ay deggan tahay.

Koolada ku salaysan biyaha, sida ku cad nuxurka qiimaha kala soocida adag, content adag waa sare, qiimuhuna waa qaali.

Filimka dhalaalaya iyo roogagga, sida waafaqsan shuruudaha badeecada, badanaa waxay isticmaalaan 10, 12 iyo 15 micrometer, filimadu waxay ka dhumuc weyn yihiin qiimaha sare; Filimka kuleylka (Horay loo dahaadhay), sida waafaqsan dhumucda filimka iyo qaybta dahaarka EVA, oo si caadi ah loo isticmaalo 1206, dhumucda filimka 12 micrometer, dahaarka EVA 6 micrometer, waxaa loo isticmaali karaa inta badan dahaarka, haddii loo baahdo shuruudo gaar ah oo loogu talagalay badeecada qoto dheer ee la embossed, soo jeedi in la isticmaalo noocyo kale oo filim hore loo dahaadhay, sida 1208, 1508 iwm., iyo koror u dhigma oo kharashka ah.

Xarunta Suuqgeynta iyo Adeegga FarsamadaTababar Farsamo Injineero xirfadlayaal ah oo ay soo dirtay GREAT ayaa mas'uul ka ah rakibidda qalabka iyo shaqada guddi-samaynta isku mar, tababarka hawl-wadeennada isticmaalaha.

Macaamiishu waa inay qaataan Visa-ga, tigidhka soo laabashada, qolka safarka oo dhan iyo cuntada, isla markaana ay awoodaan mushahar dhan 100.00 USD maalintii.

Mawduuca Tababarka:

Dhammaan mashiinnada waxaa la dhammeeyay dhammaan hagaajinta iyo tijaabinta aqoon-is-weydaarsiga GREAT ka hor inta aan la keenin, qaab-dhismeedka farsamada, hagaajinta qaybaha, hawlgalka korontada ee badhanka, iyo arrimaha u baahan fiiro gaar ah, dayactirka maalinlaha ah ee qalabka, iwm., Si loo hubiyo shaqada caadiga ah ee qalabka, ka dib.

Dammaanad:

13 bilood oo loogu talagalay qaybaha korontada, adeeggu waa cimri dhan, marka aad weydiisato qaybaha dayactirka, waan kuu soo diri karnaa isla markiiba, macaamiishu waxay awoodaan inay bixiyaan khidmadda rarista. (Tan iyo taariikhda iibka laga bilaabo keenista iyo sabuuradda, 13 bilood gudahood)

Sharaf shirkad

Soo rarista iyo baakadaynta

Aqoon-is-weydaarsi

Warshadda kooban