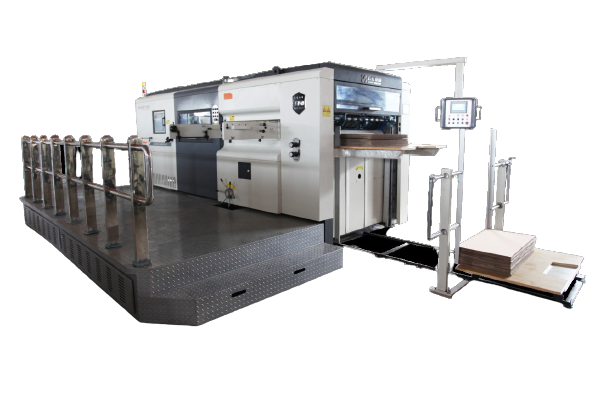

Century MWB 1450Q (oo leh xariijimo) Qalab-jarista Die-ka ee Semi-Auto ah

| Moodel | MWB1450Q |

| Cabbirka ugu badan ee Warqadda | 1480*1080 mm |

| Cabbirka Warqadda Ugu Yar | 550 * 480 mm |

| Cabbirka ugu badan ee Jarida | 1450*1050 mm |

| Cadaadiska ugu badan ee Jarida | 300x104N |

| Kala duwanaanshaha Kaydka | Loox jiingado leh ≤ 9 mm |

| Saxnaanta Jarida Die | ±0.5 mm |

| Xawaaraha ugu Badan ee Farsamada | 4000s/saacaddii |

| Hagaajinta cadaadiska | ±1 mm |

| Xadka Hore ee Ugu Yar | 8MM |

| Cabbirka Chase-ka Gudaha | 1480*1080 mm |

| Awood Guud | 21KW (ka reeb goobta shaqada |

| Cabbirka Mashiinka | 7750*4860*2440 mm (Ku dar goobta shaqada, qalabka quudinta kahor) MWB1620Q |

| Cabbirka Mashiinka | 5140*2605*2240 mm (Ka reeb goobta shaqada, qalabka quudinta kahor) MWB1620Q |

| Wadarta Miisaanka | 19t |

Qaybta Quudinta

√Nidaamka quudinta gacanta oo wax ku ool ah.

√Nidaamka qaadista xaashida xaashida ee otomaatiga ah.

√Tilmaamaha dhinaca ee booska xarunta tuulmada warqadda.

√Waxaa lagu dabaqi karaa E, B, C, A biibiile iyo derbi labanlaab ah.

Qaybta Jarida Die

√Habka qufulka badhanka riixitaanka ee pneumatic-ka ah si loo hubiyo in si ammaan ah oo fudud loo beddelo saxanka jarista.

√Nidaamka khadka dhexe ee loogu talagalay in si dhakhso ah loo jaro oo loo beddelo maaskaro.

√Nidaamka jilbaha si loo yareeyo cadaadiska ugu badan ee ilaa 400 tan

√Nidaamka is-saliidda otomaatiga ah iyo madaxa-bannaan si loogu shaqeeyo si habsami leh iyo cimri dheer

√Albaabka badbaadada iyo qalabka sawir-koronto si ammaan ah loogu shaqeeyo.

Qaybta Xarigga

√Qaab-dhismeedka sare ee xariijimaha ayaa kor loo qaadi karaa si loo furo qalabka lagu rakibayo oo loo beddelo.

√Nidaamka khadka dhexe ee loogu talagalay dejinta makiinada si dhakhso ah looga saaro qalabka iyo beddelka shaqada

√Qalab quful ah oo qaabaysan, dabacsan oo si fudud loo xidhi karo loona dabcin karo qalabka wax lagu xidho.

√Dareeraha sawirka iyo daaqadda badbaadada oo loo qalabeeyay hawlgal ammaan ah.

√Nidaamka jajabinta nus-xariiqdu wuxuu ka dhigayaa geeska qabsashada mid aan la furin.

Qaybta Bixinta

√Jiidashada dhinaca iyo hore si loo hubiyo in si fiican loo is dulsaaro.

√Nidaamka gaarsiinta baaldiga

√Qalabka baaridda sawir-qaadista ee loogu talagalay gelitaanka iyo hawlgalka badbaadada.

Qaybta Xakamaynta Korontada

√Tiknoolajiyadda Siemens PLC l si loo hubiyo socodsiinta aan dhibka lahayn.

√Qaybaha korontada waxay ka yimaadeen Siemens, Schneider.

√Dhammaan qaybaha korontada waxay buuxiyaan heerka CE

| Magaca qaybta | Summada |

| dhalista ugu weyn | NSK |

| Silsiladda wadista ugu weyn | RENOLD |

| Beddelaha Soo Noqnoqda | YASKAWA |

| Qaybaha Korontada | Siemens/Schneider |

| Encoder-ka | OMRON |

| Dareemayaasha sawirka | Panasonic/Omron |

| Matoorka ugu weyn | Siemens |

| Qaybta sambabada | AirTac/SMC |

| PLC | Siemens |

| Guddi Taabasho | Siemens |

Quudiyaha Hore

Quudinta hore waxay ka caawisaa diyaarinta xaashida xigta iyo sameynta beddelka degdega ah ee xaashida. Marka hawlwadeenku uu xaashida ku quudinayo mashiinka jarjaraha, hawlwadeen kale ayaa isku mar diyaarin kara xaashiyo kale. Marka xaashida lagu quudiyo, xaashida lagu diyaariyo qalabka quudinta hore waxaa loo riixi karaa qalab kor u qaadis ah oo otomaatig ah. Tani waxay badbaadin doontaa qiyaastii 5 daqiiqo oo diyaarinta xaashida mid walba waxayna kordhin doontaa wax soo saarka.

Guddi hawlgal oo leh gacan la dhaqaajin karo // Siemens Smart line Touch Panel

Qaybta Quudinta

√Kaamerada si loola socdo xaaladda qaybta keenista gudaha

√Nidaamka qaadista tuulmada otomaatiga ah

√ Qalabka hagaajinta farqiga quudinta ee u dhexeeya xaashiyaha iyo qabsatooyinka.

√Daaqadda badbaadada iyo dareemaha sawirka waxay bixiyaan ilaalin loogu talagalay hawlwadeenka iyo mashiinka marka daaqadda badbaadada furan tahay.

√ Riixista saxanka si loo hubiyo in xaashidu aysan waligood si xad dhaaf ah u quudin ilaa ay ka dhintaan

√Joojiyaasha dhinaca si ay u ilaaliyaan tuulmada had iyo jeer bartamaha oo ay u gaaraan go'yaal fudud oo sax ah.

Dareemaha sawirka si loo ilaaliyo qaadista tuulmada had iyo jeer waqtigii loogu talagalay quudinta xaashida.

Qaybta Jarida Die

√ Saxanka jarista ee Die wuxuu ka samaysan yahay 65Mn oo leh adkaysi HRC45 ah, oo ku habboon jarista die.

√Daaqad badbaado oo loogu talagalay badbaadada hawlwadeenka iyo mashiinka.

√Nidaamka xariiqda dhexe ee loogu talagalay goynta degdega ah ee qalabka wax lagu gooyo iyo beddelka shaqada.

√ Gacanta hagaajinta xoogga jarista. Fudud oo fudud.

Giraangiraha Gooryaanka oo leh farsamo gacmeed si loo hubiyo simanaanta dusha sare si loo jaro saxnaanta dhimaha.

Nidaamka is-saliidda otomaatiga ah

Mono-cast loo sameeyay gariir yar marka mashiinka shaqeynayo.

Gogosha taageerada waxaa loo hagaajin karaa cabbirro kala duwan si loo helo cabbirro kala duwan oo xaashiyo ah.

Qaybta Bixinta

√Nidaamka keenista balaastiga oo aan joogsi lahayn

√Guddiga Hawlgalka

√Daaqadda badbaadada

√ Dareemaha sawirka oo qalabaysan si loo hubiyo in mashiinku uu istaago marka wax soo galaan mashiinka qaybtan.

√Joogga dhinaca si loogu ururiyo go'yaal nadiif ah

Daaqadda fiirinta si aad u hubiso ururinta xaashida oo aad u sameyso hagaajin lagama maarmaan ah haddii loo baahdo.

Qalabka hagaajinta qaabka xaashida

Xakamaynta Korontada

CPU Module//Siemens Simatic S7-200

Beddelaha Soo Noqnoqda ee Yaskawa

Relays-ka Schneider, contactors-ka iyo wixii la mid ah.

Baararka Gripper, oo laga sameeyay agab aluminium ah oo hawada sare ah.

Laba qaybood oo dheeraad ah oo ah qalabka qabashada ayaa lala soo rari doonaa mashiinka iyagoo ah qaybo dayactir ah.

-300x179.jpg)

-300x204.jpg)

-300x179.jpg)

-300x200.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)