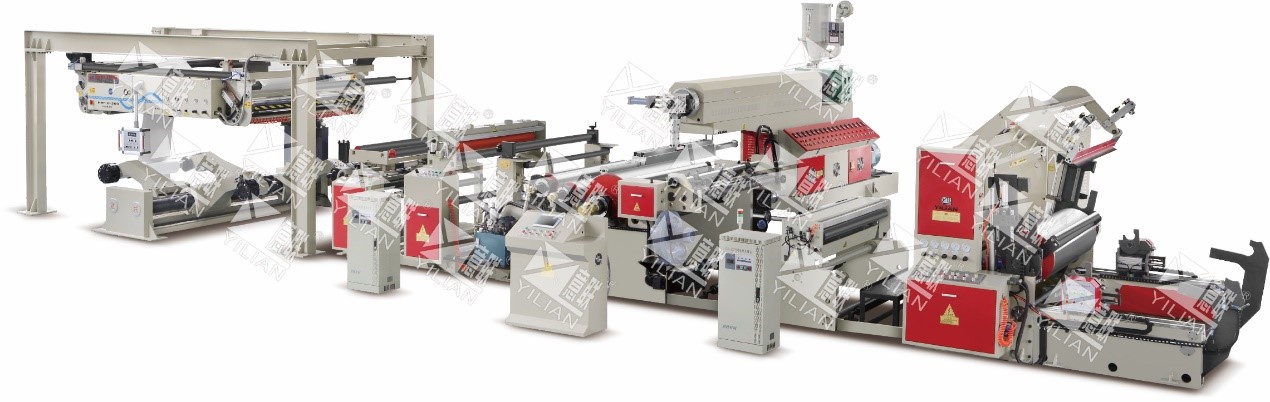

Muchina weWSFM1300C weKuputira Pepa rePE otomatiki

| Resin inotsvedzerera ine laminating | LDPE, PP nezvimwewo |

| Zvishongedzo zvepasi zvesuit | bepa (80—400g/m²) |

| Kumhanya kukuru kwemuchina | 300m/min (kushanda nekukurumidza kunoenderana nekukora kwekuputira, upamhi) |

| Upamhi hwekunamira | 600—1200, upamhi hwechitenderedza chinongedzo: 1300mm |

| Ukobvu hwekunamira | 0.008—0.05mm (Sikuruu imwe chete) |

| Kukanganisa kwekukora kwekunamira | ≤±5% |

| Ganda rekugadzika kwemagetsi otomatiki | 3—100kg yakazara |

| Huwandu hweextruder hwakanyanya | 250 kg/awa |

| Roller inotonhorera yemusanganiswa | ∅800×1300 |

| Dhayamita yeSikuruu | Chiyero che ∅110mm35:1 |

| dhayamita yepamusoro yekusunungura | ∅1600mm |

| Dhayamita yepamusoro yekudzosera shure | ∅1600mm |

| Dzorera dhayamita yepakati pepepa: 3″6″ uye dhayamita yepakati pepepa reDzorera shure: 3″6″ | |

| Extruder inotyairwa ne45kw | |

| Simba rose | anenge 200 Kw |

| Kurema kwemuchina | inenge 39000kg |

| Chiyero chekunze | 16110 mm×10500 mm ×3800 mm |

| Ruvara rwemuviri wemuchina | Gireyi netsvuku |

1. Chidimbu chekusunungura (nePLC, servo ichisunungura)

1.1 Furemu yekusunungura mhepo

Maumbirwo: Furemu yekusunungura isina shaft ye hydraulic

Chinovhara cheBA chinoumba chikamu chakakosha chemutsetse welamination uye chinoiswa pamusoro pechinomira pasi pebhiriji. Chinobvumira kuenderera mberi kwemupumburu wepepa uripo kusvika kune mumwe mupumburu wepepa unotevera pasina kumira kwekugadzirwa.

Mukati memafuremu edivi re splicer mune misoro miviri inosuduruka uye chikamu chepakati chinosuduruka. Pamusoro payo pane mapuranga maviri e nip.

Mupumburu wecapstan, mupumburu wereverse idler uye sisitimu yekutamba kaviri zvinoumba chikamu chekuunganidza mapepa chinokwanisa kuunganidza mapepa anosvika kana kupfuura kureba kwesplicer.

Muchina uyu unoshandiswa kuburikidza nepaneru yekushanda iri pamuchina

Kumhanya kwekubatanidza bepa Max.300m/min

a) kana simba repepa riri pamusoro pe0.45KG/mm, max. 300m/min;

b) kana simba repepa riri pamusoro pe0.4KG/mm, max. 250m/min;;

c) kana simba repepa riri pamusoro pe0.35KG/mm, max. 150m/min;;;;

Upamhi hwepepa

Kureba kwakanyanya 1200mm

Hurefu hwemaminiti 500mm

Kumhanya CE-300

300m/min

Ruzivo rwepneumatic

Kumanikidzwa kwekuisa 6.5 bar

Kudzvanywa kudiki kwebhaa 6

Muenzaniso CE-300

Simba 3.2kVA, 380VAC/50Hz/20A

Vheji yekudzora 12VDC/24VDC

1.1.1 Yakazvimiririra hydraulic shaft spindle clamp ruoko rwemhando mbiri rwekusunungura ruoko, isina air shaft, hydraulic loading, inochengetedza mari yekurodha chimiro chemuchina. Kuchinjana otomatiki AB shaft auto reel, kutambisa zvinhu zvishoma.

1.1.2 dhayamita yekusunungura yepamusoro: ¢1600mm

1.1.3 Auto tension setting range: 3—70kg full margin

1.1.4 kunyatsoita kwesimba: ± 0.2kg

1.1.5 pepa guru: 3” 6”

1.1.6 Sisitimu yekudzora kushushikana: mhando yemubato wekuona kushushikana nekuona kushushikana kwepotentiometer chaiyo, kutonga kwepakati kwePLC inorongwa

1.1.7 Sisitimu yekudzora dhiraivha: PIH silinda braking, mhinduro ye rotary encoder nekukurumidza, kudzvanya kwakaringana kudzora vharuvhu yakavharwa loop control, programmable controller PLC centralized control

1.1.8 Kugadzika kwesimba: Nekugadzika kwevharuvhu yekumanikidza kwakarurama

1.2 Rudzi rwekuchengetera rwechishandiso chekunhonga otomatiki, chekucheka

1.2.1 Kuchengeta kunofambiswa nepneumatic motor buffer, ita shuwa kuti kugadzikana kwakasimba pakusarudza bepa.

1.2.2 chimiro chekucheka chakasiyana

1.2.3 PLC inoverenga otomatiki kumhanya kweshaft itsva, uye chengetedza kumhanya nekukurumidza kwemutsetse mukuru

1.2.4 Gamuchira roller yekudzvanya zvinhu, chicheki chakatyoka zvinhu. chinja kudzora kwetension, gadzirisa zvese zvinogona kupedzwa otomatiki

1.2.5 Roller change pre alarm,: dhayamita yekushanda kana yasvika 150mm., muchina ucharidza alarm

1.3 Kudzora kugadzirisa: sisitimu yekudzora kugadzirisa putter yemagetsi (chimiro chekutanga)

2. Corona (Yilian customized)

Simba rekurapa Corona: 20 kw

3. Hydraulic lamination chikwata:

3.1 Maroller matatu ane laminating compound structure, back press roller, anogona kuita kuti compound roller bear ishande zvakaenzana, compound yakasimba.

3.2 Kubvisa silicon rabha roller: chigadzirwa chakagadzirwa zviri nyore kuona kubva painotonhorera roller, Hydraulic inogona kudzvanya zvakasimba.

3.3 Chimiro chefirimu rakakombama rinopetana,: chinogona kuita kuti firimu rikurumidze kuiswa

3.4 Compound feed zvinhu kugadzirisa roller inogona kukunda firimu zvinhu ukobvu zvisina kuenzana nezvimwewo kushaya simba

3.5 Muchina wekuputira une simba guru unokurumidza kudhonza mucheto wetsvina.

3.6 Chinotenderera chinocheka zvinhu zvinobuda pamwe chete

3.7 Roller inotenderera inofambiswa nemota zvichienderana nemota

3.8 Mota inofambiswa necompound roller inodzorwa neJapan frequency controller

Zvakatsanangurwa:

(1)chinotenderera chakabatanidzwa:¢ 800 × 1300mm 1pcs

(2)chinotenderera rabha: ¢ 260 × 1300mm 1pcs

(3)chinotenderera chinodzvanya:¢ 300 × 1300 mm 1pcs

(4)Silinda yemafuta akabatanidzwa:¢63 × 150 2pcs

(5)bvisa chinotenderera:¢130 × 1300 1pcs

(6)11KWmota(SHANGHAI) seti imwe

(7)11KW Frequency converter (JAPAN YASKAWA)

(8)chinobatanidza chinotenderera:(2.5"2 1.25"4)

4. Chinoburitsa zvinhu (chinogadzirisa kukwirira kwechinhu otomatiki)

4.1 Dhayamita yescrew: ¢ 110, Extruder yepamusoro inosvika :250kg/h (tekinoroji yeJapan)

4.2 T-die (Taiwan GMA)

4.2.1 Upamhi hwechiumbwa: 1400mm

4.2.2 Upamhi hunoshanda hweMould: 500-1200mm

4.2.3 Mukana wemuromo weFold:0.8mm, ukobvu hwekufukidza: 0.008—0.05mm

4.2.4 Kukanganisa kwekunamira ukobvu: ≤ ± 5%

4.2.5 Tubhu remagetsi rinodziya mukati, rinopisa zvakanaka, tembiricha inowedzera nekukurumidza

4.2.6 Nzira yakavharirwa zvachose, Kugadzirisa upamhi hwekuzadza

4.3 Midziyo yenetwork inochinja nekukurumidza

4.4 Kufamba mberi nekumashure, kunogona kusimudza otomatiki Trolley, kukwirira kwenzvimbo: 0-100mm

4.5 Mould 7 areas control. Screw barrel 8 area control. Connector 2 area control inogamuchidza infrared heating units.

4.6 Giya guru rekuderedza simba, ZANO RAKAOMA (Guo tai guo mao)

4.7 Dhijitari yekudzora tembiricha kudzora tembiricha otomatiki

Zvikamu zvikuru:

(1) mota yeAC ine simba re45kw (SHANGHAI)

(2) Chinoshandura mafrequency e45KW (JAPAN YASKAWA)

(3) Dhijitari tembiricha controller 18pcs

(4) injini yekufamba ine simba re1.5KW

5. Mudziyo wekucheka banga rakatenderera wePneumatic

5.1 Chishandiso chekugadzirisa chinochinjika cheTrapezoidal screw, chinja upamhi hwekucheka kwepepa

5.2 Mucheka wePneumatic Pressure

5.3 5.5kw mupendero wekumanikidzwa kwakanyanya unonyudza

6. Chikwata Chekudzosera Kumashure: 3D chimiro chebasa rinorema

6.1 Kudzosera shure Furemu:

6.1.1 Muchina wemagetsi wemhando yekukweshana unodzoreredza mafambiro emagetsi maviri, kucheka nekunhonga zvinhu zvakapedzwa otomatiki nekukurumidza, kuburitsa zvinhu otomatiki.

6.1.2 Dhayamita yepamusoro yekudzosera shure: ¢ 1600 mm

6.1.3 kumhanya kwekutenderera: 1r/min

6.1.4 kushushikana:3-70kg

6.1.5 Kunyatsonaka kweKunetsana: ± 0.2kg

6.1.6 pepa guru: 3″ 6″

6.1.7 Sisitimu Yekudzora Kushushikana: Chigadziko chesilinda chinoyangarara chimiro chemhando yeroller inoyangarara, kushushikana kunoonekwa nekushandisa potentiometer chaiyo, uye chinodzora chinorongwa PLC chinodzora kushushikana pakati. (Japan SMC low friction cylinder) seti imwe chete

6.1.8 Sisitimu Yekudzora Dhiraivha: 11KW mota inotyaira, kutenderera kwekumhanya kwe encoder, Senlan AC inverter dual closed-loop control, programmable controller PLC centralized control. Seti imwe chete

6.1.9 Kugadzika Kwekunetsana Kunogara: Kugadzika Kwekudzora Kudzvanywa Kwakakodzera (Japan SMC)

6.1.10 Kugadzika kwekubatidza kwetaper: zvakatemwa necomputer screen, PLC control, kushandurwa ne electric/air ratio (Japan SMC)

6.2 Chishandiso Chekudya Nekucheka Chinozvigadzirira

6.2.1 Kubatanidza Marongero Ekutsigira Anodzorwa nePLC kuti atungamirire mota kuti ibvise zvinhu kubva paroller inokwesha

6.2.2 Muchina wekucheka wakazvimiririra weHydraulic

6.2.3 Kuverenga otomatiki kwemaitiro ekutora kwePLC, kutsiviwa kwevhoriyamu kunopedzwa nekiyi

6.2.4 Basa rekutsigira roller, kucheka zvinhu, kugadzirisa patsva, nezvimwewo. Zvapedzwa otomatiki

6.2.5 Magadzirirwo

(1) Chinotenderera chinokweshana: ¢700x1300mm bhaa rimwe chete

(2) Winding mota: 11KW (Shanghai Lichao) 1 set

(3) Giya rinobururuka pasi: giya rinosimudza magiya rinorema pamusoro pechinhu chakaomarara (Thailand Mau)

(4) Inverter: 11KW (Japan Yaskawa) seti imwe

(5) Bhokisi regiya rinotenderera rinotsigira: 1 seti yesimba

(6) Chinoderedza kumhanya: zino rakaoma 1 seti yesimba

(7) Chinoderedza kumhanya kwekufamba uchitenderera: seti imwe yesimba

(8) Nzvimbo yekuburitsa mvura inoyerera

7. Auto air shaft puller

8. Chikamu cheDrive

8.1 Mota huru, bhandi rekutumira rinoshandisa bhandi rinoenderana

8.2 Mota inosanganisa, inodzosera kumashure uye inosunungura: Bhandi rekutyaira rinoshandisa giya re arc, cheni uye bhandi rinotenderera

8.3 Giya guru rekutyaira: Giya rehelical rinonyudzwa mumafuta, Chimiro chegiya rehelical rinotumirwa nemutsara

9. Chikamu Chekudzora

Kabhineti yemagetsi yakazvimirira, kutonga kwepakati, nzvimbo yakasanganiswa ine mashandiro ekabhineti yekudzora yepakati. Sisitimu ye otomatiki yemuchina inoshandisa seti yemudziyo wePLC (hollsys) ine kugona kwakanyanya kwekugadzirisa, uye masaini ekukurukurirana emuchina-muchina achishandisa network communication pakati peinterface. PLC, extrusion unit, man-machine dialogue interface pakati pe driving system uye inoumba system ye automatic control yakabatanidzwa. Kune chero ma parameter anogona kuiswa, ne automatic calculation, memory, detection, alarm, nezvimwewo. Inogona kudzvanywa kwechishandiso chekuona, kumhanya, coating thickness, speed uye mamiriro akasiyana ekushanda.

10. vamwe

11.1 Chinotenderera Chinotenderera: Anodization yakaoma yeruminiyamu alloy gwara rinotenderera, maitiro ekufamba

11.2 Mudziyo wemagetsi mashoma weFrance Schneider, omron Japan, nezvimwewo.

11. mhando yezvikamu

11.1 PLC (Beijing Hollysys)

11.2 Sikirini yekubata (TAIWAN)

11.3 frequency converter:Japan Yaskawa

11.4 Mota huru: SHANGHAI

Silinda yekukweshana yakaderera 11.5 (Japan SMC)

11.6 AC CONTACTOR (Schneider)

Bhatani re11.7 (Schneider)

11. Musanganiswa usingachinji (Taiwan)

Vharuvhu inotonga kumanikidzwa ye 11.9 cylinder (Taiwan)

11.10 Vharuvhu yekutsinhana yemagineti (Taiwan)

11.11 vharuvhu yekudzora kumanikidzwa kwakarurama (SMC)

12. Mutengi pachake anopa zvinhu

12.1 Nzvimbo yemidziyo nenheyo

12.2 Zvinhu zvinopihwa makabati emagetsi emuchina

12.3 Kupa mvura kumidziyo yemuchina mukati nekunze kwegedhi (mutengi anogadzira chitofu chemvura)

12.4 Kupa gasi kumuchina unopinda nekubuda mudumbu

12.5 Pombi yekuburitsa mweya nefeni

12.6 Kuunganidza, kurodha uye kuburutsa zvinhu zvepasi zvechishandiso chapera

12.7 Zvimwe zvinhu zvisina kunyorwa muchibvumirano

13. Rondedzero yezvikamu zvekuchengetedza:

| Aihwa. | Zita | Zvakatsanangurwa. |

| 1 | Thermocouple | 3M/4M/5M |

| 2 | Mutongi wekupisa | Omron |

| 3 | Vharuvhu inodzora zvinhu zvishoma | 4V210-08 |

| 4 | Vharuvhu inodzora zvinhu zvishoma | 4V310-10 |

| 5 | chinja chepedyo | 1750 |

| 6 | Kutumira kwakasimba | 150A pamwe ne75A |

| 7 | switch yekufamba | 8108 |

| 10 | mudziyo wekudziyisa | ϕ90*150mm,700W |

| 11 | mudziyo wekudziyisa | ϕ350*100mm,1.7KW |

| 12 | mudziyo wekudziyisa | 242*218mm,1.7KW |

| 13 | mudziyo wekudziyisa | 218*218mm,1KW |

| 14 | mudziyo wekudziyisa | 218*120mm,800W |

| 15 | Bhatani reSchneider | ZB2BWM51C/41C/31C |

| 16 | jongwe remhepo | |

| 17 | Tepi yekupisa kwakanyanya | 50mm*33m |

| 18 | tepi yetelflon | |

| 19 | Chifukidziro chekorona chinotenderera | 200*1300mm |

| 20 | Pepa remhangura | |

| 21 | sefa yechidzitiro | |

| 22 | Maburi anotenderera | 150*80*2.5 |

| 23 | chinongedzo chemhepo | |

| 24 | pfuti yemhepo | |

| 25 | pombi yemvura | 80A ne40A |

| 27 | screws nezvimwe | |

| 28 | cheni yekudhonza | |

| 29 | bhokisi rezvishandiso |

Zvikamu zvikuru nemufananidzo:

Kusunungura (Auto splicer) → web guides → Corona treatment → Kubvisa uye kusanganisa chikamu cheEdge Trimming → Kudzosera kumashure