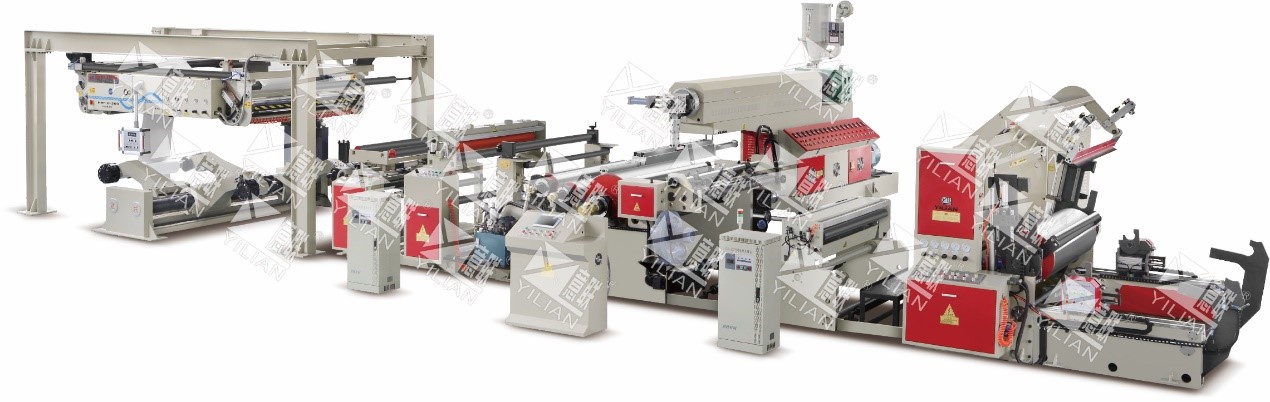

WSFM1300C Tsis Siv Neeg Ntawv PE Extrusion Txheej Tshuab

| Haum rau lamination resin | LDPE, PP thiab lwm yam |

| Cov khoom siv hauv paus | ntawv (80—400g/m²) |

| Maximum mechanical speed | 300m/min (ua haujlwm ceev nyob ntawm seb lub txheej tuab, dav) |

| Qhov dav ntawm txheej | 600—1200, qhov dav ntawm cov menyuam qhia: 1300 hli |

| Txheej tuab | 0.008—0.05 hli (Ib lub ntsia hlau) |

| Qhov yuam kev ntawm txheej tuab | ≤ ± 5% |

| Nws pib qhov chaw teeb tsa ntau yam | 3—100kg tag nrho cov npoo |

| Qhov ntau tshaj plaws ntawm cov extruder | 250 kg/teev |

| Cov menyuam txias sib xyaw | ∅800 × 1300 |

| Txoj kab uas hla ntawm cov ntsia hlau | ∅110mm piv 35: 1 |

| Max unwind diameter | ∅1600mm |

| Maximum rewind diameter | ∅1600mm |

| Txoj kab uas hla ntawm daim ntawv unwind: 3″ 6″ thiab txoj kab uas hla ntawm daim ntawv rewind: 3″ 6″ | |

| Extruder tsav los ntawm 45kw | |

| Tag nrho lub zog | txog 200 Kw |

| Qhov hnyav ntawm lub tshuab | txog li 39000 kg |

| Sab nraud qhov ntev | 16110 hli × 10500 hli × 3800 hli |

| Xim ntawm lub cev tshuab | Grey thiab Liab |

1. Tshem tawm ib feem (nrog PLC, servo unwinding)

1.1 Tso lub thav duab kom so

Qauv: Hydraulic ncej-tsis muaj unwinding ncej

Lub BA series splicer ua ib feem tseem ceeb ntawm cov kab lamination thiab tau teeb tsa rau saum lub rooj sawv ntsug hauv qab tus qauv choj. Nws tso cai rau kev sib txuas ntxiv ntawm cov ntawv yob uas twb muaj lawm mus rau cov ntawv yob tom ntej yam tsis muaj kev nres ntawm kev tsim khoom.

Hauv cov thav duab sab ntawm lub tshuab txuas yog 2 lub taub hau txuas uas txav tau thiab ib feem txhawb nqa nruab nrab uas txav tau. Saum toj no yog 2 lub yob txuas.

Lub capstan yob, reverse idler yob thiab ob chav dancer system tsim cov ntu sau ntawv uas muaj peev xwm sau ntawv txog li 4 npaug ntawm qhov ntev ntawm lub splicer.

Lub tshuab ua haujlwm los ntawm lub vaj huam sib luag ua haujlwm ntawm lub tshuab

Kev sib txuas ntawv ceev Max.300m / feeb

a) thaum daim ntawv muaj zog tshaj 0.45KG/mm, siab tshaj 300m/min;

b) thaum lub zog ntawv siab tshaj 0.4KG / hli, siab tshaj 250m / feeb;

c) thaum lub zog ntawv siab tshaj 0.35KG / hli, siab tshaj 150m / feeb; ; ;

Qhov dav ntawm daim ntawv

Qhov siab tshaj plaws 1200 hli

Yam tsawg kawg nkaus 500 hli

Ceev CE-300

Siab tshaj 300m/feeb

Cov ntaub ntawv txog cua

Teeb tsa siab 6.5 bar

Qhov siab tsawg kawg nkaus 6 bar

Qauv CE-300

Fais fab 3.2kVA, 380VAC/50Hz/20A

Kev tswj hwm hluav taws xob 12VDC / 24VDC

1.1.1 Tus kheej hydraulic ncej spindle clamp caj npab hom ob chav ua haujlwm-chaw nres tsheb unwinding, tsis muaj cua ncej, hydraulic loading, txuag tus nqi ntawm kev thauj khoom mechanical qauv. Tsis siv neeg AB ncej auto reel alternation, tsawg dua pov tseg ntawm cov khoom.

1.1.2 Qhov siab tshaj plaws ntawm txoj kab uas hla: ¢ 1600mm

1.1.3 Qhov chaw teeb tsa tsis siv neeg: 3-70kg tag nrho cov npoo

1.1.4 qhov kev nruj nruj: ± 0.2kg

1.1.5 ntawv tseem ceeb: 3 "6"

1.1.6 Lub kaw lus tswj kev nruj: hom ncej ntawm lub tshuab ntes kev nruj los ntawm qhov tseeb potentiometer nrhiav kev nruj, qhov kev tswj hwm ntawm lub programmable PLC

1.1.7 Lub kaw lus tswj hwm tsav tsheb: PIH lub tog raj kheej nres, lub rotary encoder tawm tswv yim sai sai, qhov tseeb siab tswj lub valve kaw lub voj voog tswj, programmable maub los PLC centralized tswj

1.1.8 Qhov chaw teeb tsa: Los ntawm qhov kev tswj hwm qhov siab ntawm lub valve

1.2 Khaws hom kev xaiv tsis siv neeg, txiav khoom siv

1.2.1 Khaws cia tsav los ntawm lub cev muaj zog pneumatic buffer, xyuas kom ruaj khov thaum xaiv daim ntawv.

1.2.2 cov qauv txiav sib cais

1.2.3 PLC pib xam qhov ceev ntawm lub qhov tshiab, thiab khaws qhov ceev nrog qhov ceev ntawm kab tseem ceeb

1.2.4 Tau txais cov ntaub ntawv nias rau cov menyuam, cov khoom siv txiav tawg. kev tswj hwm kev ntxhov siab hloov pauv, pib dua txhua yam tuaj yeem ua tiav tau

1.2.5 Kev hloov pauv ua ntej lub tswb ceeb toom,: txoj kab uas hla ua haujlwm thaum ncav cuag 150 hli., lub tshuab yuav ceeb toom

1.3 Kev tswj kom zoo: photoelectric putter rectifying control system (bst qauv)

2. Corona (Yilian customized)

Lub zog kho mob Corona: 20 kw

3. Chav tsev lamination hydraulic:

3.1 Peb lub log laminating compound qauv, rov qab nias roller, tuaj yeem ua rau cov menyuam sib xyaw ua ke muaj zog txawm tias, sib xyaw ruaj khov.

3.2 Tshem tawm cov roj hmab silicon roller: cov khoom sib xyaw yooj yim rau saib ntawm cov menyuam txias, Hydraulic tuaj yeem nias kom nruj.

3.3 Cov qauv nkhaus dov zaj duab xis flattening,: tuaj yeem ua rau zaj duab xis xa tawm sai

3.4 Cov khoom siv pub mis sib xyaw kho cov menyuam tuaj yeem kov yeej cov khoom siv zaj duab xis tuab tsis sib npaug thiab lwm yam tsis muaj zog

3.5 Lub tshuab cua siab nqus cov ntug seem sai sai.

3.6 Lub tshuab txiav qhov hluav taws xob sib xyaw

3.7 Cov menyuam sib xyaw ua ke yog tsav los ntawm lub cev muaj zog nyob ntawm seb

3.8 Lub cev muaj zog uas tsav los ntawm cov menyuam sib xyaw ua ke yog tswj los ntawm Nyiv Pooj tswj zaus

Cov Lus Qhia Tshwj Xeeb:

(1) Cov menyuam sib xyaw: ¢ 800 × 1300mm 1pcs

(2) cov menyuam roj hmab: ¢ 260 × 1300mm 1pcs

(3) nias lub menyuam: ¢ 300 × 1300 hli 1pcs

(4) lub tog raj kheej roj sib xyaw: ¢63 × 150 2pcs

(5) tev tawm cov menyuam: ¢130 × 1300 1pcs

(6) 11KW lub cev muaj zog (SHANGHAI) 1 teeb

(7) 11KW Zaus converter (Nyiv Pooj YASKAWA)

(8) tig lub connector: (2.5 "2 1.25" 4)

4. Extruder (tsis siv neeg qhov siab kho)

4.1 Lub hau ntswj: ¢ 110, Max extruder txog: 250kg / h (Japanese technology)

4.2 T-die ( Taiwan GMA )

4.2.1 Pwm dav: 1400mm

4.2.2 Pwm zoo dav: 500-1200mm

4.2.3 Qhov sib txawv ntawm daim di ncauj pwm: 0.8 hli, txheej tuab: 0.008—0.05 hli

4.2.4 Qhov yuam kev ntawm txheej tuab: ≤ ± 5%

4.2.5 Lub raj cua sov hluav taws xob sab hauv cua sov, cua sov zoo heev, kub nce sai sai

4.2.6 Txoj kab uas kaw tag nrho, Kev hloov kho qhov dav ntawm cov khoom ntim

4.3 Cov khoom siv network hloov pauv sai

4.4 Pem hauv ntej thiab nraub qaum taug kev, tuaj yeem nqa Trolley, nqa ntau yam: 0-100 hli

4.5 Pwm 7 thaj chaw tswj qhov kub thiab txias. Lub hau ntswj 8 seem tswj qhov kub thiab txias. qhov txuas 2 thaj chaw tswj qhov kub thiab txias siv cov khoom siv cua sov Infrared.

4.6 Lub thawv iav txo hwj chim loj, HARD TOOTH (Guo tai guo mao)

4.7 Lub tshuab tswj qhov kub thiab txias digital tswj qhov kub thiab txias tsis siv neeg

Cov khoom tseem ceeb:

(1) 45kw AC lub cev muaj zog (SHANGHAI)

(2) 45KW zaus converter (Nyiv Pooj YASKAWA)

(3) Cov tswj kub digital 18pcs

(4) 1.5KW lub cev muaj zog taug kev

5. Pneumatic Round riam trimming ntaus ntawv

5.1 Trapezoidal ntsia hlau transverse kho cov cuab yeej, hloov qhov dav ntawm daim ntawv txiav

5.2 Lub Tshuab Txiav Siab Siv Lub Tshuab Hluav Taws Xob

5.3 5.5kw siab siab ntug nqus dej

6. Chav Rewinding: 3D qauv hnyav

6.1 Rov qab ua dua:

6.1.1 Kev sib txhuam hom hluav taws xob ob chav nres tsheb rewinding tshuab, kev kub ceev txiav thiab xaiv cov khoom tiav, tsis siv neeg unloading.

6.1.2 Qhov siab tshaj plaws ntawm txoj kab uas hla rov qab: ¢ 1600 hli

6.1.3 dov-dhau ceev: 1r / feeb

6.1.4 kev nruj: 3-70kg

6.1.5 Kev ntsuas qhov nruj: ± 0.2kg

6.1.6 ntawv tub ntxhais: 3″ 6″

6.1.7 Lub Tshuab Tswj Kev Nruj: Lub cylinder cushion ntab cov qauv hom floating roller, qhov kev nruj yog ntes tau los ntawm lub precision potentiometer, thiab lub programmable maub los PLC tswj hwm qhov kev nruj. (Nyiv SMC qis kev sib txhuam lub tog raj kheej) 1 teeb

6.1.8 Lub Tshuab Tswj Tsav Tsheb: 11KW lub cev muaj zog tsav, lub zog teb ceev ntawm lub encoder, Senlan AC inverter ob lub voj voog kaw, lub tshuab tswj programmable PLC centralized tswj. 1 teeb

6.1.9 Kev Teeb Tsa Nruj Nruj: Kev Teeb Tsa Siab Precision (Nyiv Pooj SMC)

6.1.10 Qhov chaw teeb tsa ntawm lub zog taper: teeb tsa los ntawm lub vijtsam computer, PLC tswj, hloov pauv los ntawm hluav taws xob / cua piv (Nyiv Pooj SMC)

6.2 Tsis Siv Neeg Pub Noj thiab Txiav Khoom Siv

6.2.1 Cov Splicing Support Rollers raug tswj los ntawm PLC los tsav lub cev muaj zog kom tuav cov khoom kom deb ntawm cov menyuam txhuam.

6.2.2 Lub Tshuab Txiav Hydraulic Ywj Pheej

6.2.3 PLC tsis siv neeg suav ntawm cov txheej txheem xaiv, qhov hloov ntawm lub ntim tiav nrog tus yuam sij

6.2.4 Kev Ua Haujlwm ntawm Kev Txhawb Nqa Cov Menyuam, Cov Khoom Siv Txiav, Pib dua, thiab lwm yam. Ua tiav tsis siv neeg

6.2.5 Cov Lus Qhia Tshwj Xeeb

(1) Kev sib txhuam rau cov menyuam: ¢700x1300mm 1 bar

(2) Winding lub cev muaj zog: 11KW (Shanghai Lichao) 1set

(3) Dov lub thawv iav: lub iav reducer helical uas tawv tawv (Thailand Mau)

(4) Inverter: 11KW (Nyiv Yaskawa) 1 teeb

(5) Kev txhawb nqa lub thawv iav: 1 teeb tsa lub zog

(6) Kev txo qhov ceev: cov hniav tawv 1 teeb ntawm lub zog

(7) Kev txo qhov ceev ntawm kev taug kev: 1 teeb tsa lub zog

(8) Chaw nres tsheb hydraulic tawm

7. Lub tshuab rub cua pib

8. Tsav Tsheb

8.1 Lub cev muaj zog loj, txoj siv sia siv txoj siv sib dhos

8.2 Kev sib xyaw ua ke, rov qab thiab tsis siv lub cev muaj zog: Siv txoj siv sia siv arc iav, saw thiab synchronous siv kis

8.3 Lub thawv iav tsav tseem ceeb: Lub iav helical uas muab roj sib khi, Cov qauv iav helical sib kis kab

9. Chav Tswj Xyuas

Lub txee hluav taws xob ywj pheej, kev tswj hwm hauv nruab nrab, qhov chaw sib xyaw nrog kev ua haujlwm ntawm lub txee tswj hwm hauv nruab nrab. Lub tshuab automation system siv cov khoom siv PLC (hollsys) nrog lub peev xwm ua haujlwm siab, thiab cov lus sib tham ntawm tus txiv neej thiab tshuab siv kev sib txuas lus hauv network ntawm qhov interface. PLC, extrusion unit, kev sib tham ntawm tus txiv neej thiab tshuab ntawm lub kaw lus tsav tsheb thiab tsim ib qho kev tswj hwm tsis siv neeg. Rau txhua qhov kev teeb tsa tuaj yeem teeb tsa, nrog kev suav tsis siv neeg, nco, nrhiav pom, ceeb toom, thiab lwm yam. Puas tuaj yeem ntsuas qhov nro ntawm cov khoom siv tso saib pom, qhov ceev, tuab txheej, qhov ceev thiab lwm yam kev ua haujlwm.

10. lwm tus

11.1 Cov Menyuam Qhia: Kev ua kom tawv ntawm cov hlau txhuas qhia yob, cov txheej txheem txav mus los

11.2 Cov khoom siv hluav taws xob tsawg rau Fabkis Schneider, omron Nyiv Pooj, thiab lwm yam.

11. hom khoom seem

11.1 PLC (Beijing Hollysys)

11.2 Kov npo (TAIWAN)

11.3 zaus converter: Nyiv Yaskawa

11.4 Lub cev muaj zog loj: SHANGHAI

11.5 lub tog raj kheej tsis sib txhuam (Nyiv Pooj SMC)

11.6 AC CONTACTOR (Schneider)

11.7 khawm (Schneider)

11. Lub tshuab sib tov zoo li qub (Taiwan)

11.9 lub tog raj kheej siab tswj lub valve (Taiwan)

11.10 Lub qhov sib nqus sib pauv (Taiwan)

11.11 precision siab regulating valve (SMC)

12. Cov neeg siv khoom tus kheej muab cov chaw

12.1 Qhov chaw siv khoom thiab lub hauv paus

12.2 Cov khoom siv rau lub txee hluav taws xob tshuab

12.3 Muab dej rau cov chaw siv tshuab hauv thiab tawm ntawm lub rooj vag (tus neeg yuav khoom npaj lub tshuab dej txias)

12.4 Kev muab roj rau lub tshuab teeb tsa rau hauv thiab tawm ntawm lub stomatal

12.5 Cov yeeb nkab tso pa tawm thiab kiv cua

12.6 Sau, thauj khoom thiab tshem tawm cov khoom siv hauv paus ntawm cov cuab yeej tiav lawm

12.7 Lwm cov chaw tsis tau teev nyob rau hauv daim ntawv cog lus

13. Daim ntawv teev cov khoom seem:

| Tsis yog. | Lub Npe | Cov Lus Qhia Tshwj Xeeb |

| 1 | Lub thermocouple | 3M/4M/5M |

| 2 | Tswj qhov kub thiab txias | Omron |

| 3 | Micro-regulating valve | 4V210-08 |

| 4 | Micro-regulating valve | 4V310-10 |

| 5 | qhov sib thooj hloov | 1750 xyoo |

| 6 | Kev xa hluav taws xob khov kho | 150A 75 A |

| 7 | hloov mus ncig | 8108 |

| 10 | chav ua cua sov | ϕ90 * 150 hli, 700W |

| 11 | chav ua cua sov | ϕ350 * 100 hli, 1.7KW |

| 12 | chav ua cua sov | 242 * 218mm, 1.7KW |

| 13 | chav ua cua sov | 218 * 218mm, 1KW |

| 14 | chav ua cua sov | 218 * 120mm, 800W |

| 15 | Schneider khawm | ZB2BWM51C/41C/31C |

| 16 | cua qaib | |

| 17 | Daim kab xev kub siab | 50 hli * 33m |

| 18 | daim kab xev telflon | |

| 19 | Cover Corona roller | 200 * 1300 hli |

| 20 | Daim ntawv tooj liab | |

| 21 | lim dej ntawm qhov screen | |

| 22 | Tig cov qhov txiav | 150 * 80 * 2.5 |

| 23 | lub tshuab txuas cua | |

| 24 | phom cua | |

| 25 | dej sib koom ua ke | 80a40 ua |

| 27 | cov ntsia hlau thiab lwm yam | |

| 28 | rub saw hlau | |

| 29 | lub thawv cuab yeej |

Cov khoom tseem ceeb thiab daim duab:

Unwinder (Auto splicer) → web guiding → Corona treater → Extrusion thiab compounding ib feem Ntug Trimming → Rewinding